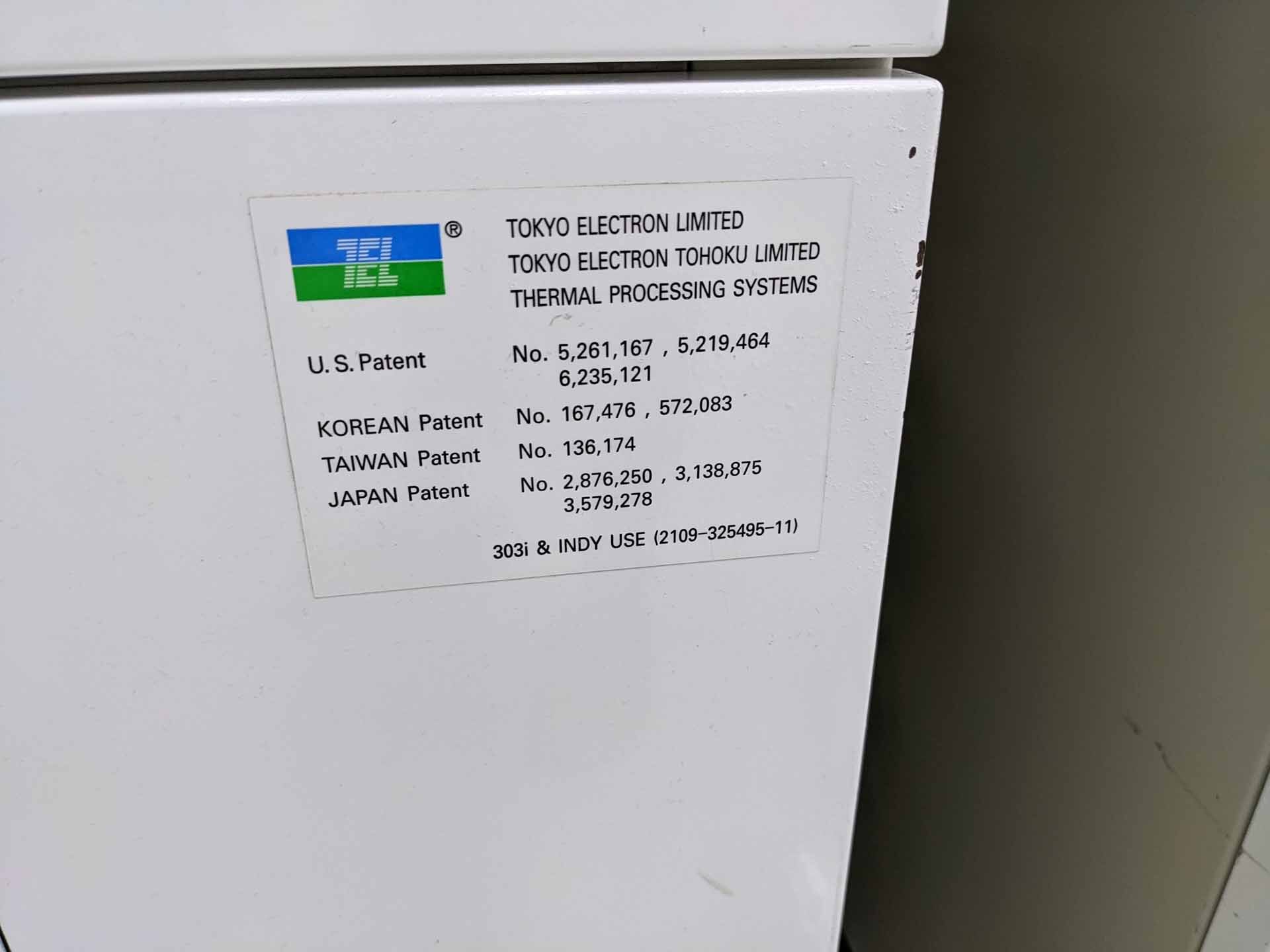

Used TEL / TOKYO ELECTRON Indy-I-L #293643279 for sale

URL successfully copied!

Tap to zoom

ID: 293643279

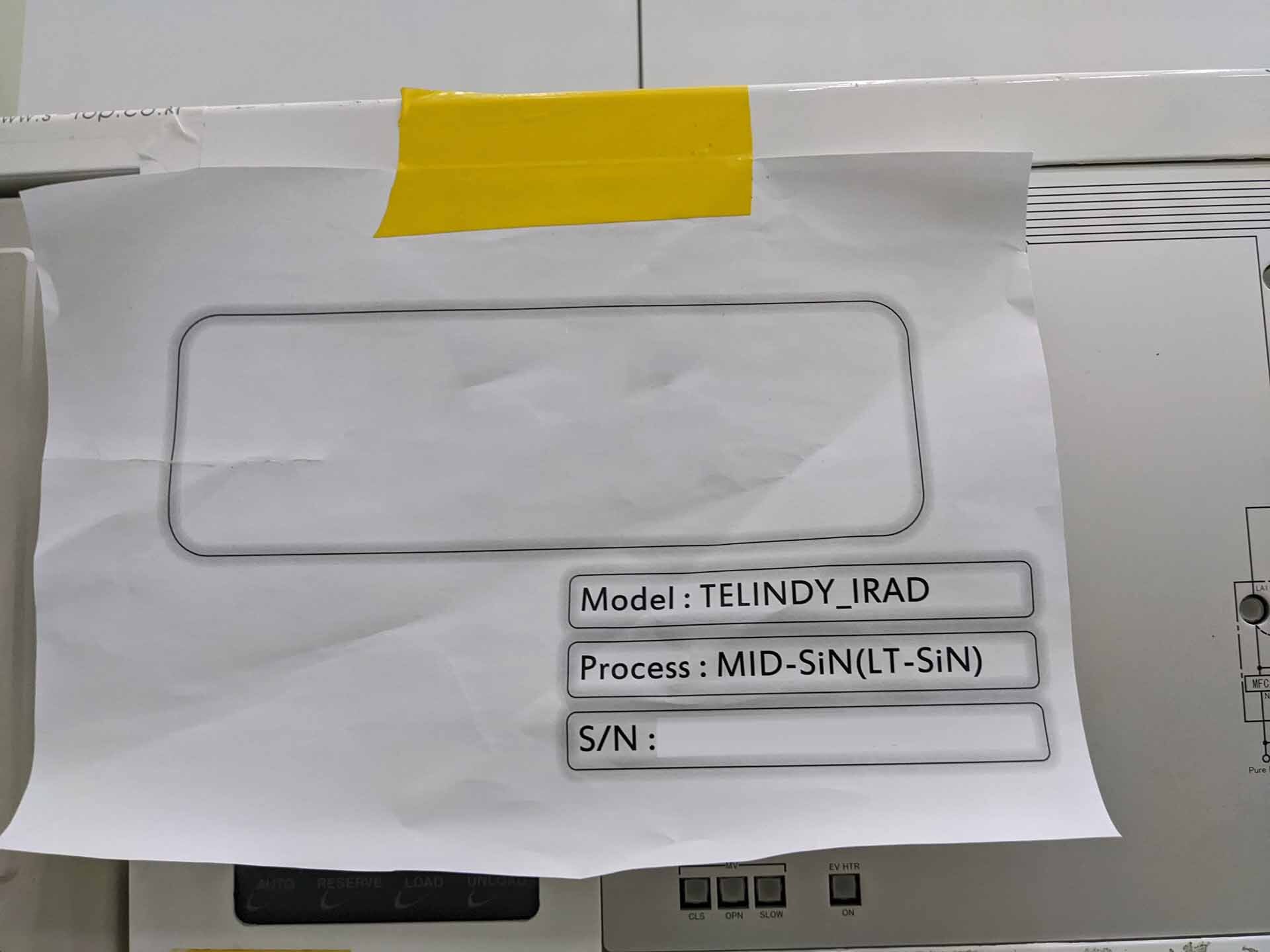

Wafer Size: 12"

Vintage: 2008

Furnace, 12"

Process: LT-NIT

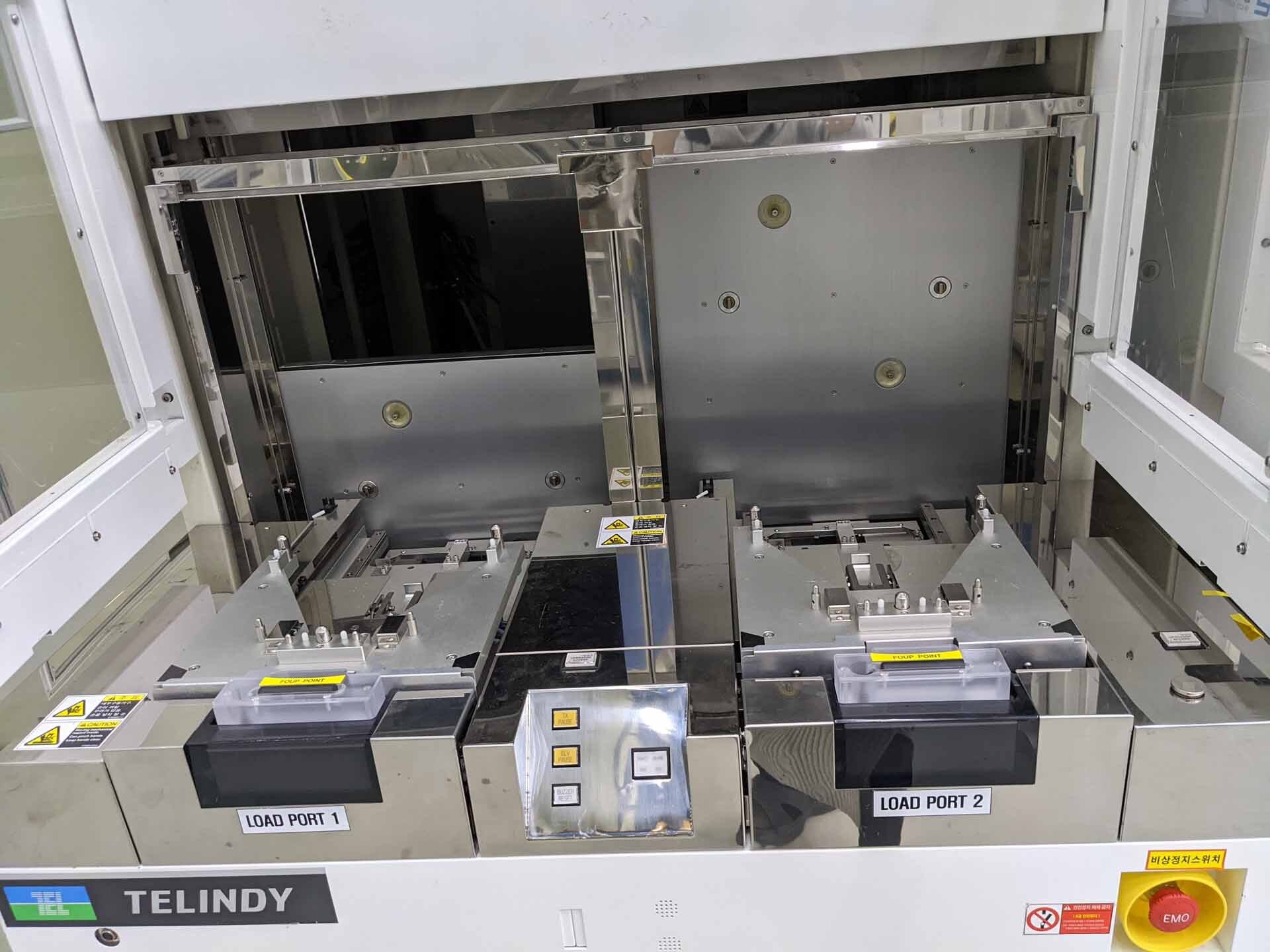

Load lock system

KAWASAKI W/T Robot

2008 vintage.

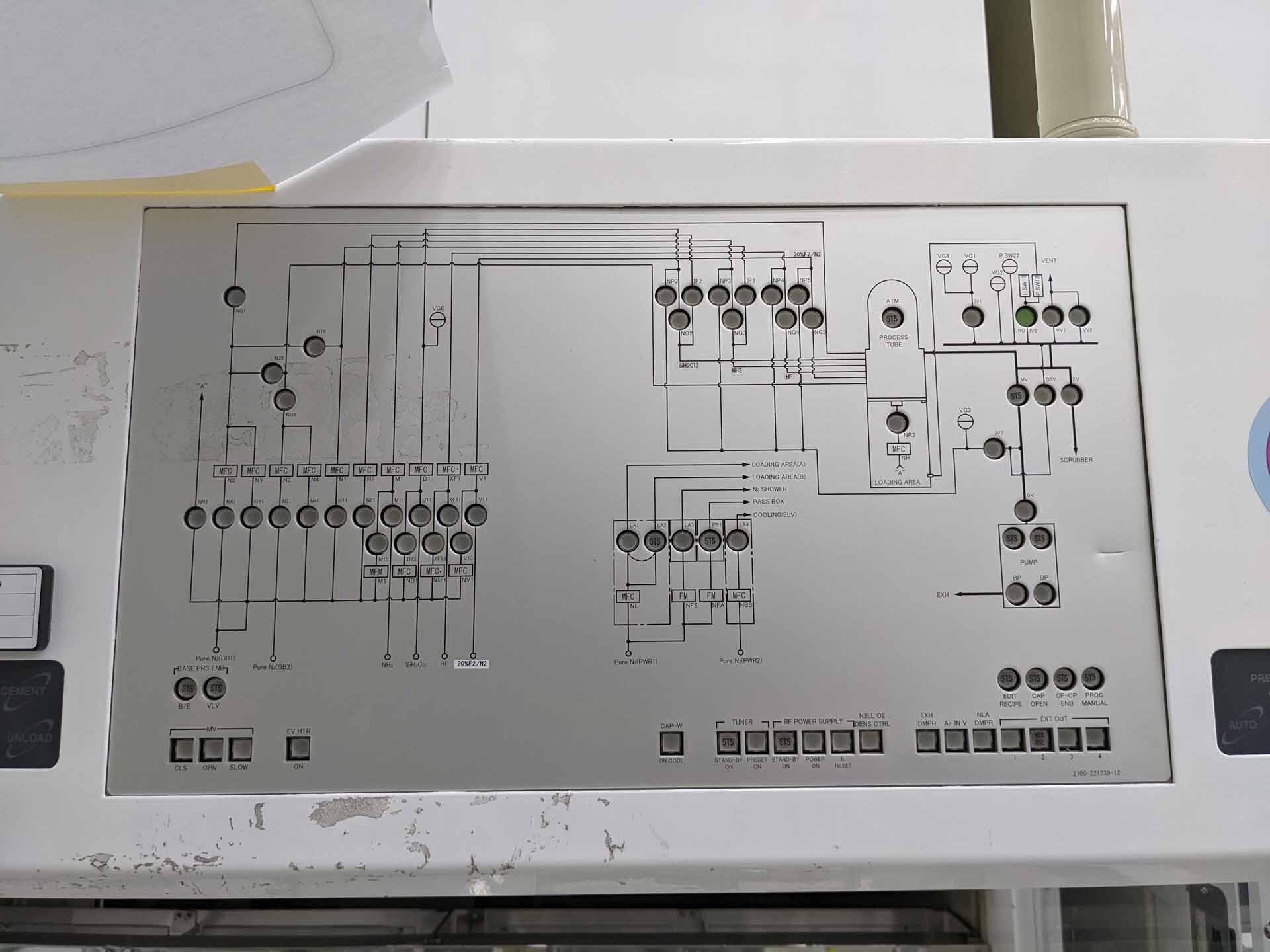

TEL / TOKYO ELECTRON Indy-I-L is an etcher/asher developed by TEL, a Japanese manufacturer of semiconductor production equipment. It is widely used for the etching and deposition of magnetic and compound semiconductor materials for a variety of applications. TEL Indy-I-L is equipped with a wide range of functions for uniform etching and deposition of large wafers up to 300mm. TOKYO ELECTRON Indy-I-L utilizes innovative technology to facilitate efficient, stable, and uniform processing. It is equipped with advanced technology, including variable temperature RF (Radio Frequency) power source and laser-interference control, to ensure uniform etching and deposition, as well as optical and topographic feedback control to ensure repeatable and stable results. Additionally, its smart controller functions allow customizable and automated control of etching and deposition processes. Indy-I-L has a large chamber capacity of 1,200L and is designed to provide a wide etching/deposition range. It is capable of processing temperature of up to 900°C with a 50mA/m 2 RF power source, and up to 2.5kV DC (Direct Current) bias voltage. TEL / TOKYO ELECTRON Indy-I-L can etch and deposit a number of wide range of materials, including rare-earth and heavy ion intosilicates, silicon, titanium, aluminum and other metals, as well as compound semiconductors like gallium arsenide, indium-phosphide and aluminum nitride. TEL Indy-I-L also has an industry leading 45µ/min etching rate, as well as an easily adjustable deposition rate of up to 20nm/min. Additionally, it is capable of high productivity with multiple wafer cluster handling of up to 40 wafers. TOKYO ELECTRON Indy-I-L can be used for a variety of different etching and deposition applications, ranging from specialized semiconductor applications to the production of everyday consumer electronics. Indy-I-L is user-friendly and designed for efficient operation. Its intuitive user interface and simple etch/deposition control functions offer easy setup and accurate control of processes, while its auto-stop function helps reduce cost and improve reliability of the etching/deposition process. Overall, TEL / TOKYO ELECTRON Indy-I-L is a powerful and versatile etcher/asher, designed to provide efficient, stable, and uniform etching/deposition of a wide range of materials for various applications. It is the perfect addition to any semiconductor fabrication facility.

There are no reviews yet