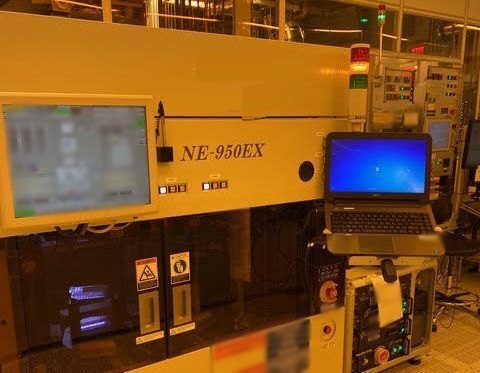

Used ULVAC NE-950EX-V #9298684 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9298684

Vintage: 2015

CCP Etcher

Capable of running: Single, 12" / Three, 6"

Automated cassette to cassette handling

(3) Wafers batch: 6" dia

(7) Wafers batch: 4" dia

(12) Wafers batch: 3" dia

(29) Wafers batch: 2" dia

Equipped ICP with magnetic field

ULVAC P/N: 3188353 High density plasma source

(2) ULVAC P/N: 3429391 Proprietary star electrodes

Dry etching technology

GaN, Sapphire, metal, ITO, SiC, AlN, ZnO

(4) Elements compound semiconductor materials

Option included

2015 vintage.

ULVAC NE-950EX-V is an etcher / asher used for etching and ashing processes in the production of semiconductor devices. This model of etcher / asher combines a wide range of etching and ashing processing capabilities in a single machine. With a substrate area of 450mm × 450mm, NE-950EX-V has a processing capacity of up to three glass wafers, one metal or organic substrate, or one piece of quartz glass. It provides a variety of etching and ashing processes including parallel etching, clip etching, deep etching, ion milling, reactive ion etching, electron beam trimming and wafer cleaning. ULVAC NE-950EX-V is equipped with a high-resolution etching microscope equipment, which utilizes diffused optical illumination for clear observation and precise alignment of each substrate. The microscope system is able to magnify up to 100x and accurately process wafers to tolerances of ± 10 microns. It is also possible to conduct etching with self-replaceable O-ring seals, as well as enables dry etching with a variety of gases. NE-950EX-V features a built-in ECR (electron cyclotron resonance) source with an electron density up to 3 x 10¹º cm⁻¹, allowing the creation of high-density plasma for etching and trimming within a total unit pressure of 5 Pa or less. This ultra-low pressure allows for improved etching uniformity and reduced departure rate from wafer surfaces. The ECR source also features a built-in digital controller, which controls electron cyclotron frequency, current mode, and automatic phase synchronizing to ensure optimum etching and trimming on all substrates. ULVAC NE-950EX-V also includes a unique secondary-field plasma lamp capable of providing ultra-high frequency plasma for superior cleaning performance. The plasma lamp runs at frequencies up to 500MHz, ensuring fast and consistent wafer cleaning. It includes an outer chamber for preventative maintenance with a 5-stage gas control machine, allowing for accurate control of all gases used during the process. NE-950EX-V also supports safety and environmental measures for semiconductor production. This includes hoods and other security devices to reduce the risk of odor and noise around the machine, as well as properly designed exhaust systems to minimize air pollution. In conclusion, ULVAC NE-950EX-V is a reliable and advanced etcher / asher, capable of providing exceptional etching and ashing performance for a variety of semiconductor devices. With its high-resolution etching microscope tool, ECR source, and ultra-high frequency plasma lamp, it sets a standard for quality and dependability in semiconductor production.

There are no reviews yet