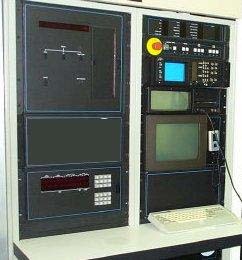

Used EATON NOVA / AXCELIS NV 10-160 #9358247 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9358247

Ion implanter

Monitor:

TFT Panel, 10"

With LED and slow scan-technology.

The Eaton/NovaEATON NOVA / AXCELIS NV 10-160 ion implanter and monitor is a semiconductor fabrication device used to control the depth and distribution of ion implantation in the manufacture of integrated circuits and other semiconductor devices. It incorporates a high-voltage DC generator, a power supply, and a vacuum system, as well as a wide range of ion sources such as GaAs, PFC, and XeCl. This machine is capable of implanting ions up to 1.6 million volts, providing a high degree of accuracy and control. The machine is equipped with an auto-oscillating shutter system which controls the spot size and depth of ions impinging on the semiconductor materials, and a source-to-target distance of up to 1.25 meters. This enables the user to precisely control the dose, energy, and ion species implanted into the substrate. This is essential for proper doping control and profile control in the fabrication process. The machine has a built-in ion beam monitor and a digital readout that continuously measures each ion species concentration and the rate of change in ion concentration from the source. The ion current is also measured during each implantation, giving a real-time status as to the consistency of the implantation process. The monitor is also capable of measuring the resistivity of implanted layers in the substrate material to ensure that the desired resistivity values are achieved. The DV 10-160 is further equipped with a computer control for loading and unloading wafers and ions, as well as for monitoring the process parameters. The software package also contains an independent verification system which allows the user to check the parameter settings of each wafer before and after implantation, thus allowing a high degree of quality control during production. In addition, this machine is equipped with mechanical jigs, which are used to hold the substrate during implantation and the target material afterwards, ensuring accurate placement and orientation of both. This further increases accuracy and precision of the implantation process. The Eaton/NovaAXCELIS NV10-160 ion implanter and monitor is an indispensable part of the semiconductor fabrication process, providing optimum control of doping profiles, resistivity, and implant dose, as well as aiding quality control and production processes.

There are no reviews yet