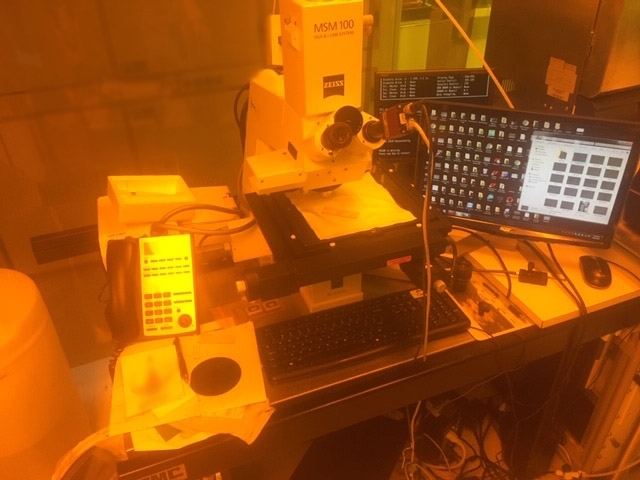

Used CARL ZEISS AIMS 248 / MSM 100 #9275806 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

CARL ZEISS AIMS 248 / MSM 100 is a mask and wafer inspection equipment designed to provide high-precision automated microscope imaging of mask and wafer surfaces. The system is capable of acquiring images of masks and wafers with high accuracy, providing advanced image processing features such as Adaptive Scanning Technology (AST) and area-of-interest (AOI) to ensure repeatable and reliable image quality. AIMS 248 / MSM 100 operates with an array of optical components which include a large field-of-view, low light level conditions, a telecentric lens, and a 100x objective lens. This provides the required resolution for fast, efficient, and reliable imaging of semiconductor surfaces. Additionally, the unit is equipped with a range of features to further ensure precision, including color encoders, image stitching, pixel-level pattern recognition, and automated cropped and filtered viewing. This enables unparalleled image clarity and accuracy for demanding applications such as process control and troubleshooting. CARL ZEISS AIMS 248 / MSM 100 has an integrated wafer mapping feature that enables efficient selection of inspection area as well as pinpointing erroneous areas in the mask or wafer. Additionally, its high-precision autofocus microscope acquisition machine provides automated acquisition of both high-resolution digital images and front-lit contact images of the mask or wafer surface. Moreover, its algorithms can detect nearly any pattern error, from simple defects to complex patterns or structures with precision. This makes it ideal for inspecting highly complex designs. In addition, the tool is designed to work with other common imaging tools such as X-ray, FTIR, SEM, UV, plasma-enhanced chemical vapor deposition (PECVD) and atomic force microscopy (AFM). This allows users to compare the data obtained from each technology for a more comprehensive view of the mask/wafer surface. Finally, the asset is fully automated, providing automated operation during inspection, measurement, and analysis. This eliminates any potential for human errors, and enables quick validation and analysis of mask and wafers. In summary, AIMS 248 / MSM 100 is an advanced mask and wafer inspection model designed to provide high-precision imaging of mask and wafer surfaces. The equipment has a range of features to ensure precision, including color encoders, pixel-level pattern recognition, automated cropped and filtered viewing, and an integrated wafer mapping feature. Additionally, it has the capability to work with other imaging technologies, allowing users to obtain a more comprehensive view of the surface in question. Finally, its automated operation ensures consistent and reliable results while eliminating potential for human errors.

There are no reviews yet