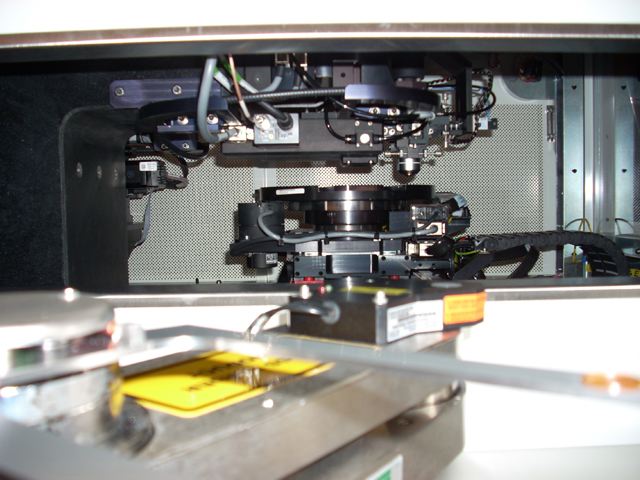

Used KLA / TENCOR Archer AIM #64588 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 64588

Overlay inspection system with MPX option

MPX - Focus Exposure Monitoring

Software Version : 3.10.06SP6

Software Options :

Archer Analyzer

SECS/GEM/HSMS

Klass Client

RDM Client

Objective FOV : 50um

No Klass Station

Configured for 8" Wafers

Two Cassette Platens

Brooks Dual Arm robot

Brooks Prealigner

Flat Display Monitor for User Interface

Keyboard and Mouse for User Interface

Push and Lock EMO

CE Marked

2000 vintage.

KLA / TENCOR Archer AIM is an automated and intuitive mask and wafer inspection equipment that is designed to enable fast, reliable and high-performance mask inspection. The system is designed to be a fast and efficient tool, capable of finding and correcting defects before they become critical and expensive. It is designed to deliver enhanced performance at higher resolutions and with fewer defects. The unit is capable of detecting and correcting defects in photomask, as well as lithographic (wafer) defects. It is designed to be user friendly, enabling non-experts to perform automated routine tasks quickly and easily, as well as to quickly detect and correct defects when found. The machine is equipped with a wide range of automated mask inspection capabilities, such as defect imaging, signature analysis, classification and quantification, defect classification analysis and pattern recognition. It also includes the latest in slit-scanning imaging and alignment, capable of capturing defects on both photomask and lithographic levels. The tool has been designed to inspect both positive and negative photomask layouts, and is capable of finding and correcting errors on a 1x nm to 5xnm resolution scale. It is also capable of detecting a broad range of defects, ranging from particles, opaque foreign material and dust to pinholes, pattern defects and misalignments. The asset is capable of detecting and correcting both medium defects, ie, those that are visible or have been detected in the field and large defects, those in the otherwise invisible range of pattern imperfections. The model is also equipped with a suite of flexible imaging tools, enabling each mask layer to be viewed at the highest resolution available. The tool also has the ability to shift focus between densely packed and spaced areas as desired, and zoom to give the user closer look at the affected region. The equipment also offers built-in fault management and logging capabilities that enable the user to quickly and easily review corrective action taken and data on automated inspection results. The system is also capable of providing fast updates on new defect information in the field and generating reports for further analysis. Finally, the unit has been designed to provide the most cost-effective solution for detecting and correcting defects, with a comprehensive suite of services, such as training, software updates and systems maintenance. The machine is also highly scalable and can be easily upgraded when necessary.

There are no reviews yet