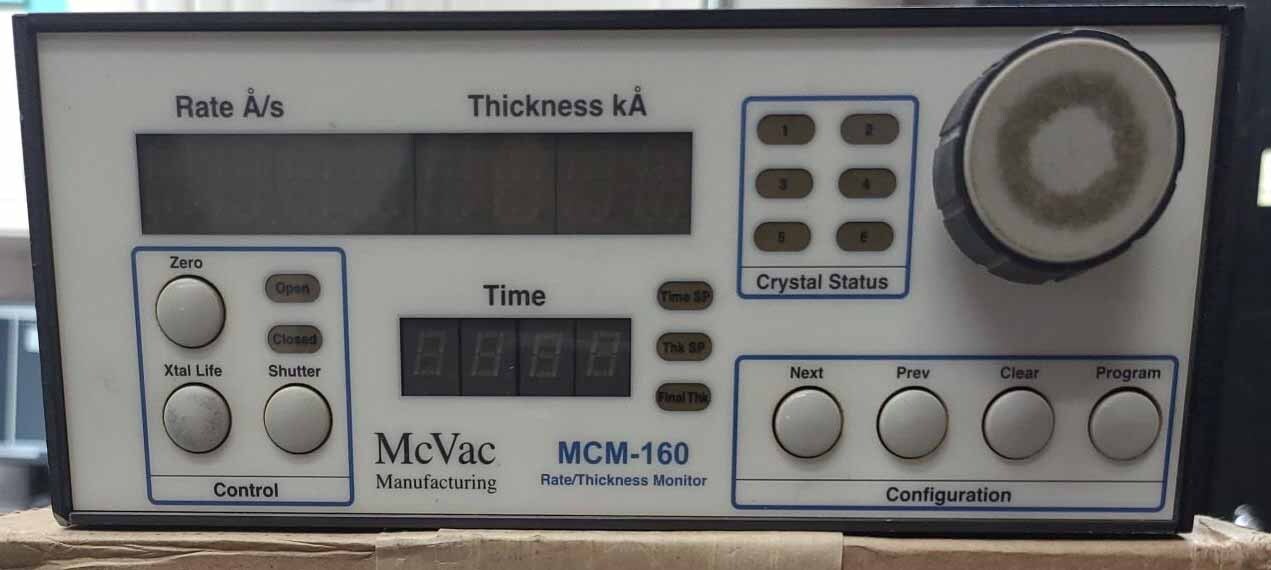

Used MCVAC MCM-160 #9266954 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

MCVAC MCM-160 Mask and Wafer Inspection equipment is an advanced imaging and inspection device that provides high-resolution imaging for wafers and masks used in semiconductor wafer fabrication. MCM-160 is an all-in-one system that includes both wafer scanning capabilities and mask inspection capabilities. MCVAC MCM-160 utilizes a novel lens array technology to acquire microscopic images of each pattern on the wafer or mask. This unit can inspect for defects and substrate-related features on wafer substrates and masks up to 200mm in diameter. MCM-160 features a 5 megapixel CCD sensor for imaging wafers. The CCD sensor has a field of view of 2.5×38×2.5 mm, and can scan a 9mm wide field of view across the active area of a single wafer at a resolution of up to 5µm. The CCD sensor can be configured to scan in different directions and directions to capture both vertical and lateral features on the wafer. This enables precise imaging of fine details on the wafer, making MCVAC MCM-160 a particularly suitable inspection machine for the detection of pinholes, small oxide features, small contact/via anomalies, small particles, and line breaks down to 5µm. MCM-160 also has mask inspection capabilities, which can be used to inspect masks up to 200mm in diameter. The tool is equipped with a 4 megapixel filter array CCD and an adjustable focus lens that work together to acquire microscopic images of each pattern on the mask. The asset is capable of detecting defects such as line breaks, shorts and contamination at resolutions down to 6µm. The model also has a feature detection capability, which can be used to detect line-end or pattern position discrepancies that may affect the quality of the mask. In addition to high-resolution image acquisition, MCVAC MCM-160 can also perform wafer alignment and critical dimension measurements. The equipment is equipped with an auto alignment feature that is capable of accurately positioning the wafer and aligning the system to the imaging direction of the wafer. This ensures the unit can properly capture the features on the wafer. MCM-160 also has a critical dimension analysis feature, which can measure feature edges and diameter sizes accurately. Overall, MCVAC MCM-160 Mask and Wafer Inspection machine is an advanced imaging and inspection device that provides high resolution imaging of wafers and masks. The tool has both wafer scanning and mask inspection capabilities that enable precise detection of defects and substrate-related features on the wafer or mask. It is also capable of performing wafer alignment and critical dimension measurements.

There are no reviews yet