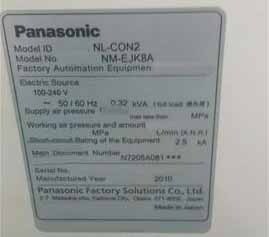

Used PANASONIC NL-CON2 #9120574 for sale

URL successfully copied!

Tap to zoom

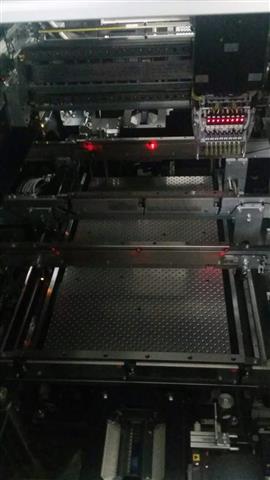

PANASONIC NL-CON2 is a highly versatile PC Board Assembly and Manufacturing Equipment. It is a reliable and efficient solution for producing high-performance products. It features two independent auto-mated production lines which can be configured for different needs. It can be used as a standalone system or with other production systems in a network configuration. NL-CON2 is designed for high-throughput production requiring short lead-times. With robust and repeatable processes, high-performance cycle times and an intuitive user interface, the unit ensures efficiency and high throughput. Advanced features include pick-and-place handling, in-line inspection, and online monitoring of production runs. For handling, PANASONIC NL-CON2 can be equipped with in-feed and out-feed conveyors, robotic handling and flexible handling in combination with its automated pick-and-place functions. This enhances the machine's throughput and repeatability, while ensuring a secure and efficient handling process. The tool also includes an offline programming mode which facilitates training and setup of the line for new components. The asset also features a vision alignment model, which allows for precise placement of components on the board. This feature makes it ideal for high-density parts and fine pitches requiring great precision. The equipment also provides in-line inspection and testing functions that enable quick and efficient feedback on component quality and board end results. Furthermore, NL-CON2 is integrated with built-in traceability and production monitoring functions. This allows the user to monitor the progress of the production runs as well as keep an accurate history of the components used in the production. This feature is also integrated with the other functions of the system, so that production data can be accessed and analyzed quickly and accurately. In conclusion, PANASONIC NL-CON2 is an innovative and efficient PC Board Assembly and Manufacturing unit. With its high-throughput capabilities, wide range of customization options, and advanced features, the machine ensures efficient production of high-performing products. Its user-friendly interface and built-in traceability and monitoring functions provide additional value to the tool. The versatile nature of the asset allows it to be easily integrated with existing production systems, thus making it an attractive solution for various large-scale production requirements.

There are no reviews yet