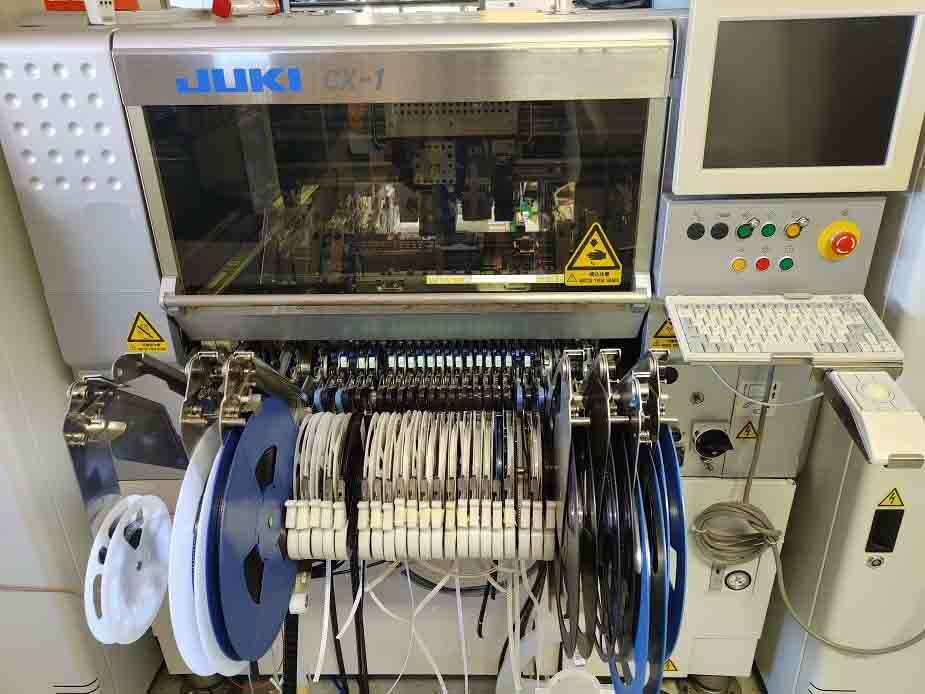

Used ZEVATECH / JUKI CX-1 #293659681 for sale

URL successfully copied!

Tap to zoom

ID: 293659681

Vintage: 2009

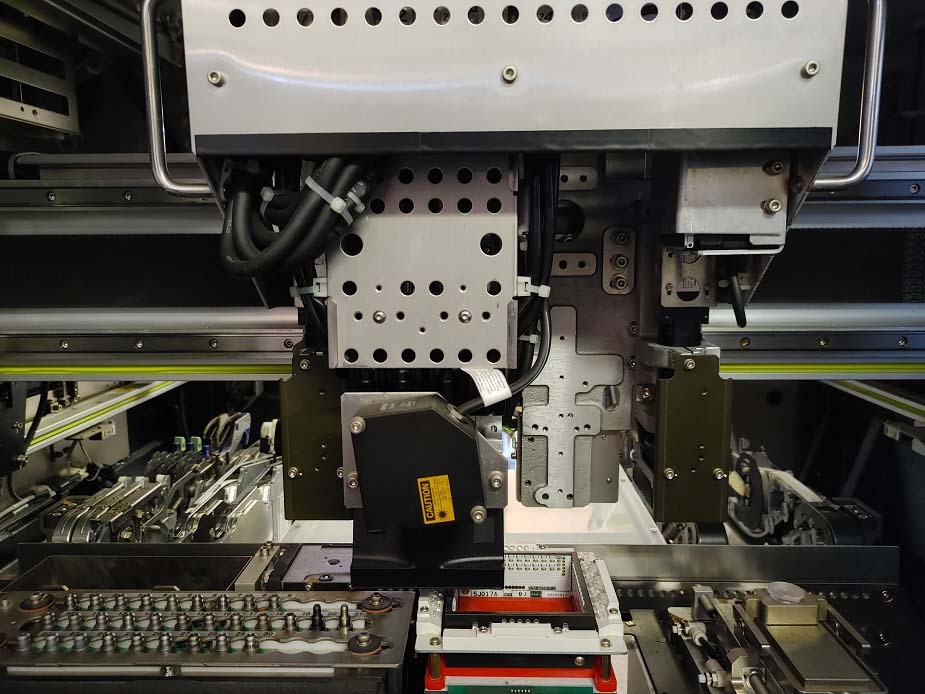

Pick and place machine

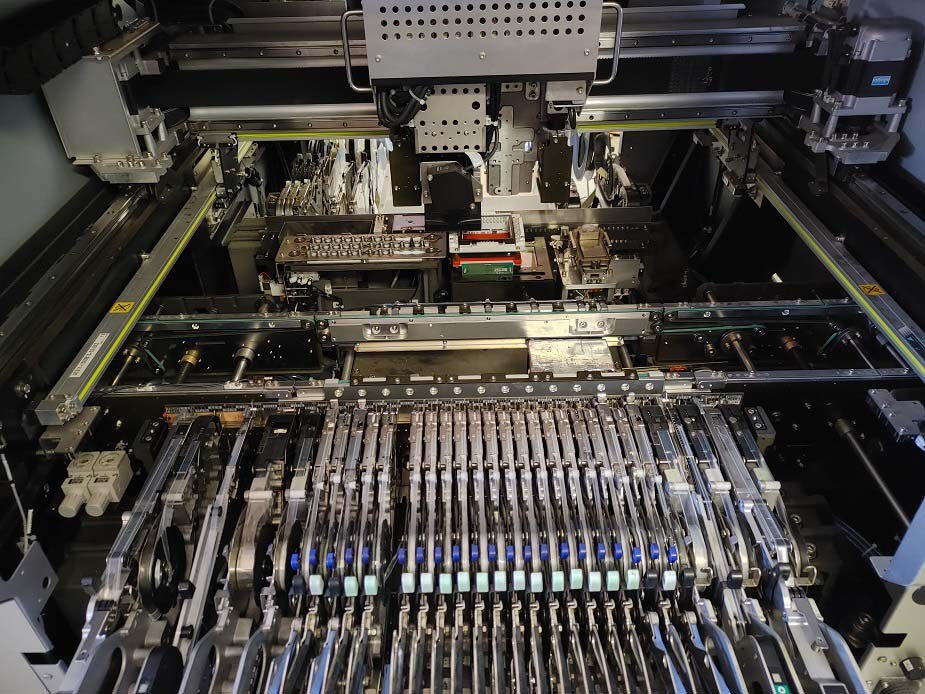

Multi nozzle laser head

(4) Nozzles

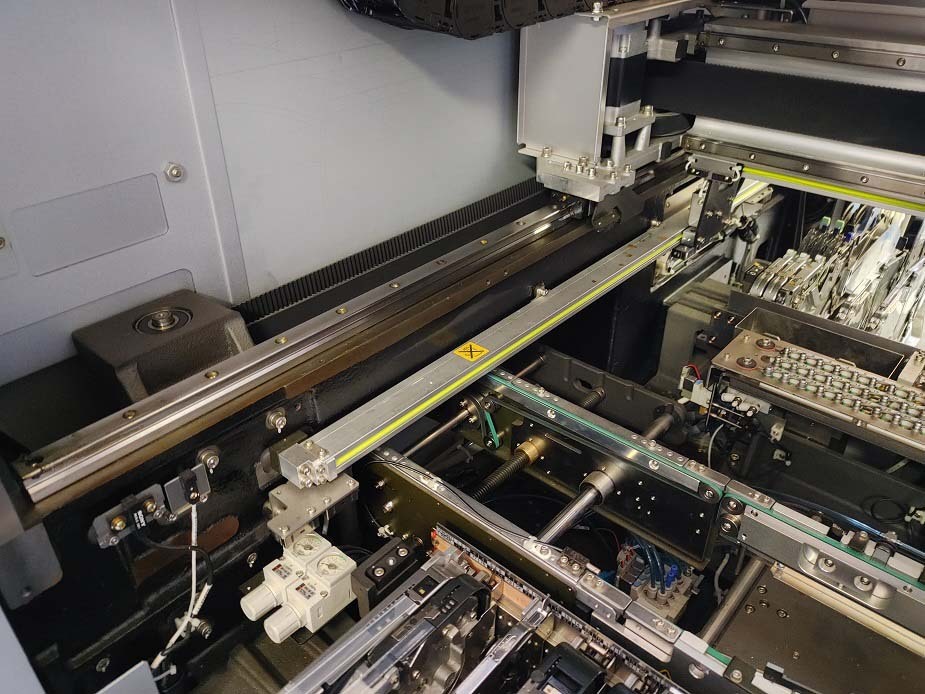

Micron optical linear scale

Placement force control

High-resolution motor theta control: 0.01° resolution

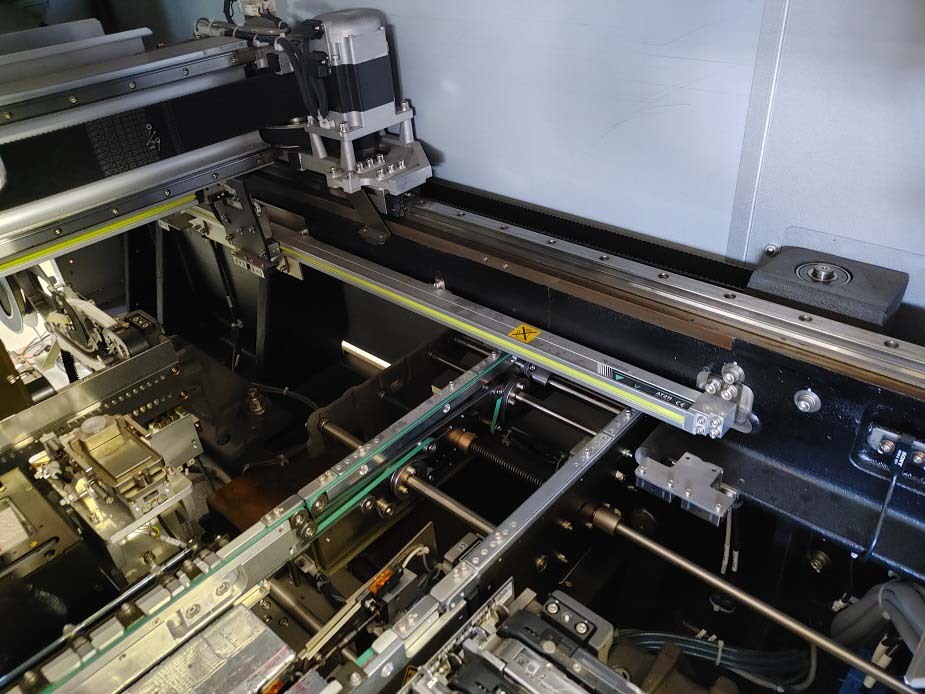

Precise substrate conveyor unit

Height measurement system

Front and rear feeder float detectors

Board fiducial offset correction system

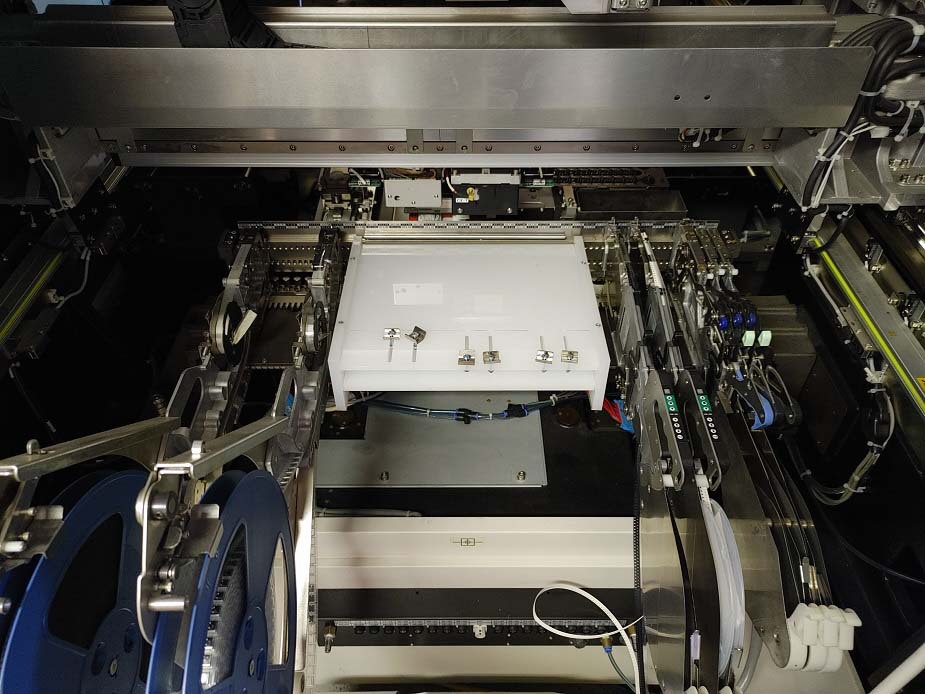

(3) Stage pass thru conveyor

Automatic nozzle

Teach pendant

Board edge clamping system

Bad mark reading via OCC

LCD Color monitor, 12"

PC

Keyboard

Trackball

High resolution vision centering system:

Tri-color

Tri-directional lighting

All-ball recognition

Mutli-imaging

Operating system: Windows XP

Running hours 442.8

2009 vintage.

ZEVATECH / JUKI CX-1 is one of the most advanced PC board assembly and manufacturing systems on the market. The equipment features a fully automated process that provides dependable and highly accurate production of high quality products. JUKI CX-1 is designed to facilitate a wide range of applications, from standard through-hole assembly to complex, high-density component placement and SMT. It is capable of quickly completing the assembly process with unparalleled precision. One of the primary benefits of ZEVATECH CX-1 is its speed. With three full-time, on-board cameras that can recognize and place components with an accuracy of greater than 800μm (0.8mm), it is able to greatly reduce production time and realize a significantly higher level of throughput compared to other assembly and production systems. To further enhance speed and accuracy, the system is also equipped with advanced vision recognition and self-tune capabilities that allow it to quickly adapt to various production conditions. In addition to speed, CX-1 is also fully programmable and comes with a full suite of user-friendly software tools that enable users to customize and personalize their production processes with seamless integration into existing systems and platforms. The unit also offers an array of advanced features such as automatic pick-and-place sequencing, recognition of overlapping components, and automatic detection of part location, making it the most efficient and capable machine in its class. In terms of performance, ZEVATECH / JUKI CX-1 is capable of delivering up to 90,000 CPH (Components Placed per Hour), which allows for a fast and reliable production process. The tool is powered by a reliable and robust motion control asset that has been specifically designed to optimize accuracy, speed, and safety. JUKI CX-1 is also capable of carrying out a variety of motion control, management, and inspection processes, including X-ray inspection, laser marking, and solder joint inspection. ZEVATECH CX-1 also features an open and modular architecture that allows it to easily integrate into existing production lines and systems. The model is designed to be user-friendly and allow for seamless integration with other computer systems, making it easy for users to quickly learn and use. Additionally, CX-1 is designed to be highly reliable, robust, and energy-efficient, allowing for flexible and cost-effective operation. In conclusion, ZEVATECH / JUKI CX-1 is a top-of-the-line PC board assembly and manufacturing equipment that offers an unprecedented level of productivity and accuracy. With its robust features, speed, and flexibility, it is the ideal system for businesses looking to produce high-quality, reliable products with precision and efficiency.

There are no reviews yet