Used ASYMTEK C 740 #9160279 for sale

URL successfully copied!

Tap to zoom

ID: 9160279

Vintage: 2004

Conformal coating machine

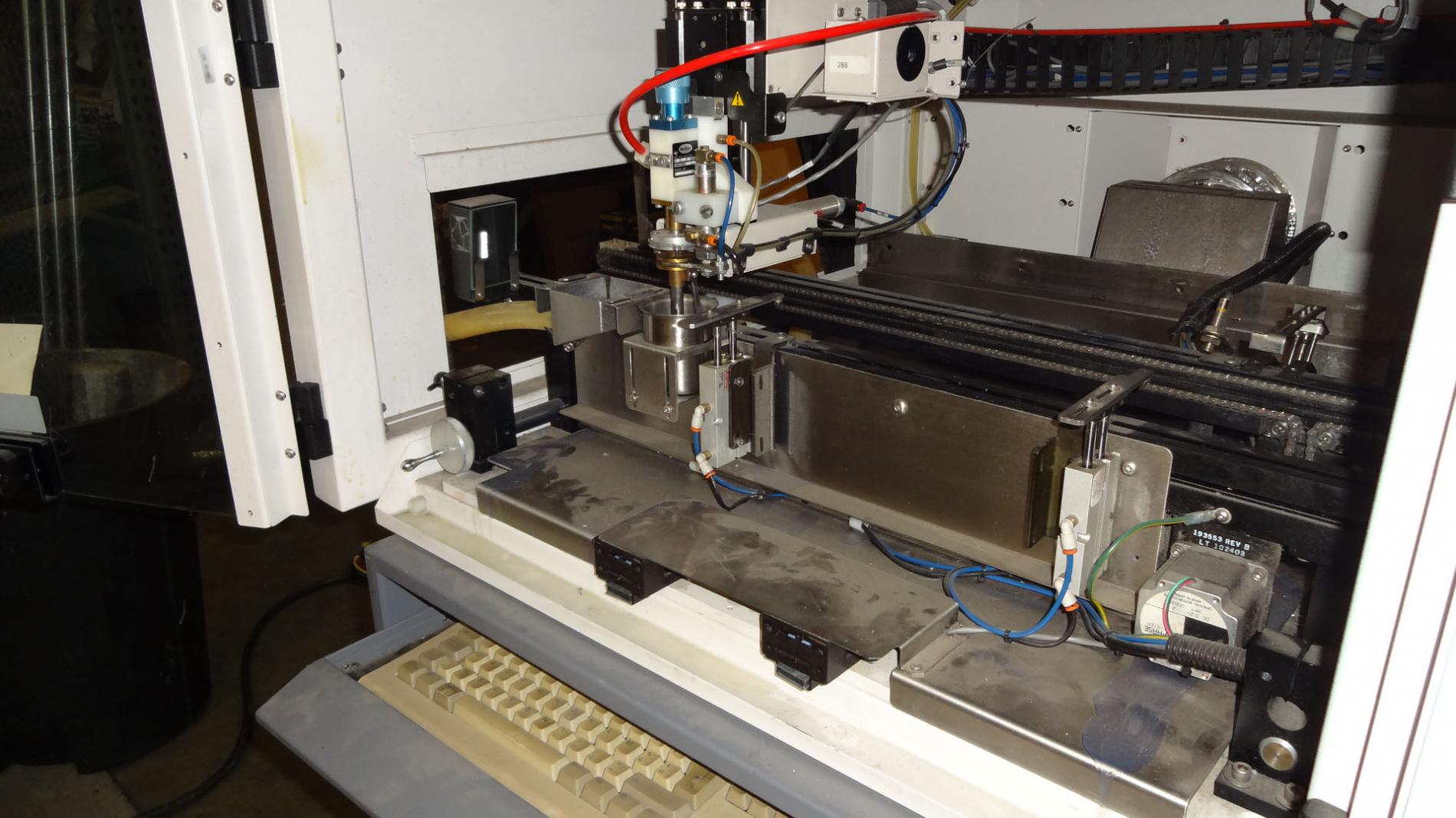

Single head

User environment: Easy coat fluid move

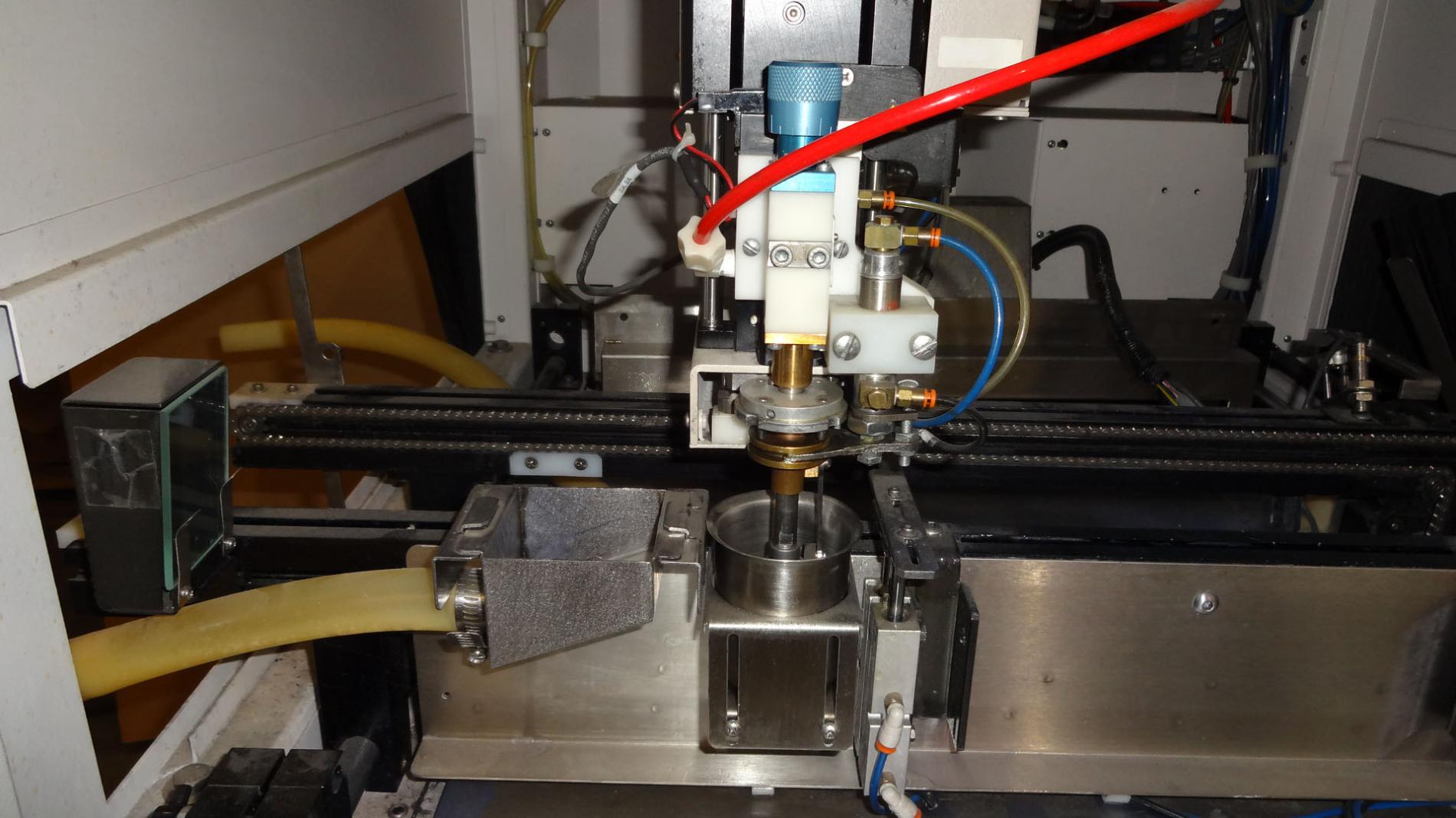

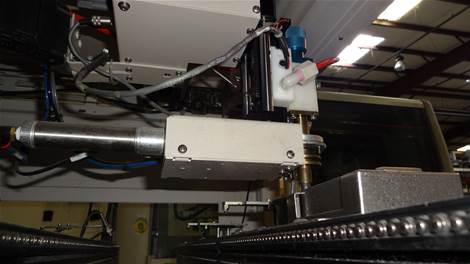

SC-200 valve

Operating system: Windows NT

Laser fan width control

Dispense area: 457 x 432 mm

Purge and solvent cups:

Door interlocks

Light beacon

Conveyor:

Chain conveyor with queue stop and pinning set

Manual width adjust 2-18 inches

System foot print: 36 x 41 inches

Power: 100 / 120 / 220 / 240

50/60 Hz, 10 amps

Motion system:

Type: Brush-less DC stepper motor

X-Y velocity:

Maximum: 508 mm/s (20 in./s)

Default: 381 mm/s (15 in./s)

Z axis velocity: 203 mm/s (8 in./s)

X-Y repeatability: ±0.025 mm (0.001 in.), 3 sigma

Z-axis repeatability: ±0.025 mm (0.001 in.), 3 sigma

X-Y resolution: ±0.025 mm (0.001 in.), 3 sigma

Z-Axis resolution: ±0.025 mm (0.001 in.), 3 sigma

Positional accuracy: ±0.13 mm (0.005 in.), 3 sigma

Dispense area:

Inline: 457 x 432 mm (18 x 17")

With solvent-purge station: 457 x 400 mm (18 x 15.75")

With fan width control: 457 x 387 mm (18 x 15.25")

Board size up to 400 mm (15.5") wide can be accommodated

Conveyor:

Inline: Standard chain conveyor with queue stop and pinning set

Manual width adjustment from 51 to 457 mm (2 to 18")

Maximum clearance: 89 mm (3.5") above and below PCB

Maximum pallet / PCB weight: 2 kg (5.5 lbs)

Computer:

Computer: Pentium PC

User interface: Monitor, keyboard and mouse

User environment: Easy coat for Windows NT

Operating system: Windows NT

Fluid delivery method: SC-104/105

Film coater module: Non-atomizing, heat-circulating system SC-204/205

Film coater module: Non-atomizing, non-circulating system

Swirl coat module: Tri-mode swirl system

Facilities requirements:

Air supply: 620 kPa (90 psi, 6.2 Bar), up to 57 liter/min (2 SCFM) max depending on configuration

Ventilation air: 0.28 m3/s @ 25 mm water column (600 SCFM @ 1.0" water column)

Nitrogen source: Required for moisture-sensitive materials – 410 kPa (60 psi, 4.1 Bar) @ 14 liter/min. (0.5 CFM)

Power (Mains): 100/120/220/240 VAC 50/60 Hz, 10 A

Noise: <70 dBA

Standard compliance: SMEMA, CE

Configured with valve, SC204 film coater

Inline machine

2004 vintage.

ASYMTEK C 740 is a high-performance automated syringe dispensing equipment designed to provide precise and repeatable dispensing of photoresist. The system offers industry leading dispensing accuracy of ± 1% (by volume), ensuring that parts of an assembly or circuit board are accurately sized. The user interface has been developed to allow fast, easy and intuitive operation, allowing users to maximize throughput and cycle time. The unique modular design of C 740 enables users to achieve greater levels of flexibility and control over the dispensing process. The unit is expandable, with up to five dispensing axes and can be configured for wide variety of applications. The machine is also optimized for low fluid pressure and usage, reducing residue and contamination. ASYMTEK C 740 is equipped with a multi-angle vision tool, ensuring accurate placement of parts and reliable dispensing onto a variety of target surfaces, including metal, plastic, glass, and foam. The vision asset also supports the automatic generation of masks, allowing photoresist patterns to be accurately and repetitively placed. The model incorporates advanced, high-speed software which can integrate into the production line for a truly automated process. Many components of the equipment can be accessed remotely, thus increasing operational efficiency. C 740 is designed for compatibility with a wide range of materials, including photoresist, epoxy, solder paste, and adhesives - allowing users to optimize process parameters and increases throughput. The system is also designed to work in both cleanroom and outdoor environments, allowing users to extend flexibility within multiple locations. ASYMTEK C 740 delivers reliable dispensing with the highest level of production quality for a wide range of photoresist applications. Easy setup and operation combined with industry leading dispensing accuracy allows this unit to provide production close tolerance in a wide variety of applications.

There are no reviews yet