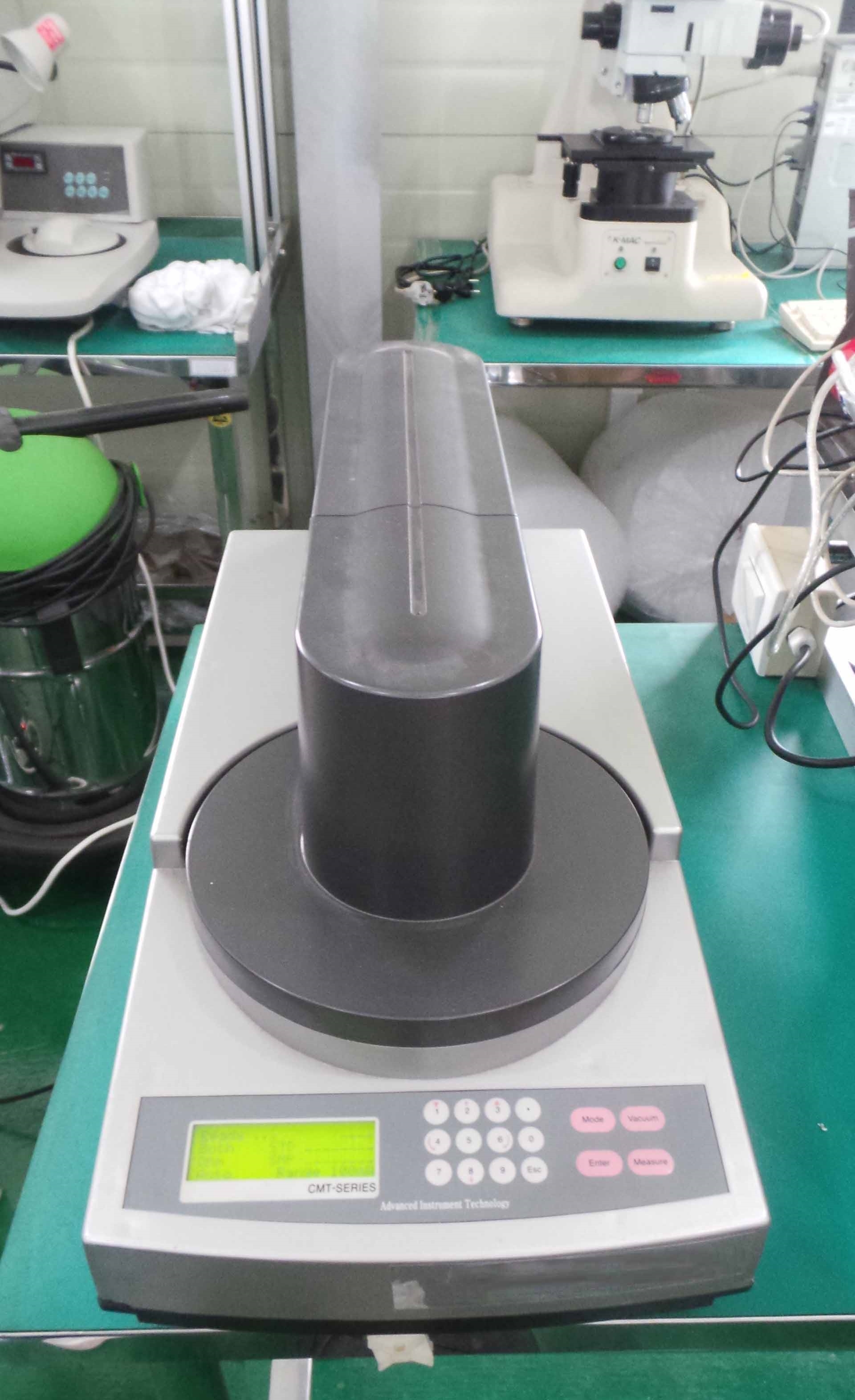

Used ADVANCED INSTRUMENT TECHNOLOGY / AIT CMT-SR2000N #9218034 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9218034

Wafer Size: 8"

Automatic system, 8"

XYZ-Axis fully automatic system

High precision JANDEL P-point probe head

Auto / Manual range selection

Built-in temperature sensor

Remote control by operating PC

Data analysis (2D, 3D map)

ASTM & SEMI Quick measurement mode

Includes:

JANDEL 4-Point probe head unit

Z-Axis robot arm

Revolution sample stage chuck (XY-Axis)

Membrane keyboard panel

LCD Display window

Remote control communication port

Vacuum hose connector (200 mm Hg)

Accessories

Operating PC

Power cable & USB Cable for remote control

AIT Reference, 3"

Specifications:

Sheet resistance measurement:

Measuring method: Contacted by 4-Point probe

Measuring range: 1 mohm / sq ∼ 2 Mohm / sq

Resistivity measurement:

Measuring method: Contacted by 4-Point probe (Input thickness)

Measuring range: 10.0 μohm·cm ∼ 200.0 kohm·cm

Measurement accuracy:

± 0.5 % (Precision resistor)

JANDEL 4-Point probe

Pin spacing: 25 mils ∼ 50 mils by 5 mil increments

Pin load: 10 gram / pin ∼ 250 gram / pin

Pin radius: 12.5 micron∼500 micron (polished 2μ diamond)

Tolerance: ± 0.01 mm

Needles: Solid tungsten carbide φ0.40 mm

Measurement condition: Wafer type, measure point interval

Save & load: Data, wafer type, measure point

Data analysis: 2D, 3D Mapping, data map

On / Off: Remote, vacuum

Data export: Excel format & printout

Measurement mode:

Auto measurement: Point interval designation by user

Quick measurement: ASTM & SEMI Mode

Point measurement: Appointment on wafer by mouse

Manual measurement: Appointment on wafer by arrow key

Measuring time:

Approximately 2 ± 1 sec / point

Operating personal computer: IBM PC / AT compatible

USB Communication

Stage chuck vacuum requirements:

Vacuum: 200 mm Hg

Vacuum hose: Urethane 4 mm

Operating & service manual

Power:

Line voltage: AC 220 V ± 10%

Electric power: 40 W, 500 mA

Line frequency: 50/60 Hz

Current source:

10 nA to 100 mA

DVM 0V to 2,000 mV.

ADVANCED INSTRUMENT TECHNOLOGY / AIT CMT-SR2000N is a high precision prober for automated component testing. It is a compact, flexible and economical combination of a wafer prober and an automated component tester. This prober provides unmatched accuracy and fast, reliable data capture. AIT CMT-SR2000N is designed to test components ranging from 100 microns to 1.5 millimeters. It features a high resolution prober based on a precise piezo motor, providing up to 10 microns of displacement resolution. This prober has an advanced motion control system, providing consistent, repeatable probing accuracy with high speed processing. It can also be programmed to capture data from multiple components simultaneously. ADVANCED INSTRUMENT TECHNOLOGY CMT-SR2000N includes an advanced probe head and advanced software capabilities for testing a variety of components. It features a high stability probe head with automatic calibration and repeatable force determination, ensuring accurate results with every test. The force range of the unit is adjustable to a maximum of 10 Newtons, making it suitable for testing a variety of components. The prober can be used in combination with any computer system to control the automated component testing. It is compatible with PC based computers, providing an open platform for fast data access and control of the prober. CMT-SR2000N also features a color touchscreen display for easy visual operation. ADVANCED INSTRUMENT TECHNOLOGY / AIT CMT-SR2000N is an excellent choice for component testing in a variety of environments. Its powerful, precise, and reliable performance, along with a range of features, makes it an ideal prober for both industrial and educational laboratories. With its easy to use interface, this prober is ideal for automating any component testing process quickly and accurately.

There are no reviews yet