Used CANON / ANELVA SPF-710H #157670 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 157670

Chrome sputtering system

Includes:

SPF-710H Instruction Manual

922-9252 Pumping Controller, MIG-820 Wide

Range Ionization Gauge Operation Manual

PRF-503 RF Generator

OF Gauge Selector

Diffusion Pump Forepressure Controller

2” Pneumatic Valve, Heating Power Controller with a temperature controller

2033/2063 Alcatel Mechanical Rotary Pump

CDP-2400/3700 Oil Diffusion Pump, Vacuum Breaker (M.P. Vent Valve)

Bridge Type Main Valve

BN86-E

NB-86S Flow Switch

Gas Feed Valve Controller

MTG-012 Thermocouple Vacuum Gauge

CMS-301 Orifice Controller and CMS-201 Flow Controller/CMS-221 Mass Flow Meter

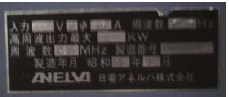

922-953 Power Supply: / 220 V / 3 Phase / 40A.

CANON / ANELVA SPF-710H is a high-end analytical sputtering equipment that is used in thin film deposition and metalization processes. It is designed for use in production and large-scale research and development applications. The system consists of various components, including a sputter source, substrate heater, drive assembly, vacuum chamber, control panel, and exhaust unit. CANON SPF-710H sputter source features a low-pressure chamber and a tungsten target. Unlike traditional sputter sources which use a radio-frequency (RF) glow discharge to vaporize the target, ANELVA SPF-710H uses a direct-current (DC) bias voltage to facilitate ion sputtering. This improves the emission uniformity and the rate of sputtering. The substrate heater is designed to maintain the temperature of the substrate during deposition, while the drive assembly provides precise control over positioning and substrate movement. The vacuum chamber of SPF-710H is constructed of high-grade stainless steel, and features a large spacious area for substrates up to 8 inches in size. A powerful vacuum pump, coupled with a noble gas delivery machine, maintains a high degree of vacuum in the chamber. This allows for fast and efficient thin film deposition. The control panel of CANON / ANELVA SPF-710H is highly sophisticated and provides the user with precision control over the various functions and parameters of the tool. It includes an intuitive graphical interface and is pre-programmed with commonly used operating conditions. Additionally, it includes various safety features to protect the user from hazardous gases and electrical shock. Finally, CANON SPF-710H includes a powerful exhaust asset to quickly and efficiently evacuate sputtered particles and gases. This is especially critical in high-vacuum deposition processes, as it helps reduce contamination and maintains a safe and healthy working environment. In summary, ANELVA SPF-710H is a comprehensive, high-end analytical sputtering model that is suitable for a wide range of thin film deposition and metalization applications. Its sophisticated components, including a sputter source, substrate heater, drive assembly, and control panel, provide a robust platform for reliable and efficient operation. Furthermore, its advanced safety features and powerful exhaust equipment ensure a safe, contamination-free working environment.

There are no reviews yet