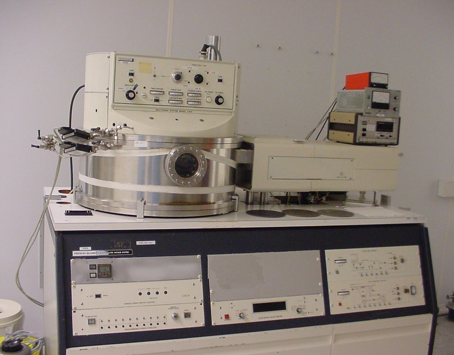

Used PERKIN ELMER 2400-8L #39101 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 39101

Vintage: 1990

Sputtering system

System:

Multi-target RF-Diode sputtering system w/ 8" load-lock

substrate table 6 1/2" dia.

PLC controlled

substrate heating for 650°C

Sputter Sources

3x 8" DC-Cathodes, 1 etch station(optional 4. target)

Vacuum:

Leybold TurbVac450

Power Supplies:

DC-Power supply, 2.5kW

1990 vintage.

PERKIN ELMER 2400-8L Sputtering Equipment is a versatile tool for thin film deposition, designed for precision and repeatability. The system is equipped with advanced features and capabilities, including chamber sizes up to 8 inches in diameter, high power target sputter sources, and advanced chamber automation. The target and substrate can be independently moved and positioned, enabling enhanced process control and uniformity of deposition. The sputtering process is highly repeatable, making 2400-8L an ideal unit for depositing thin films with accuracy and precision. The machine features an automatic substrate movement mechanism, allowing for efficient and reproducible results. The tool utilizes RF or DC power to sputter the film onto the substrate. Both processes are independent of each other, which allows for a higher degree of control and customization. The flexibility of the process means that different material layers can be sputtered on top of one another, giving rise to more sophisticated nanostructures. The asset utilizes a high-vacuum chamber, allowing for uniform deposition of materials at high pressure without compromising the integrity of the surface. Vacuum levels as low as 4x10-6 Torr can be achieved, in a uniform and cycling chamber. This allows for very precise, homogeneous deposition of conformal layers and reliable device performance. The adjustable temperature chamber design provides an additional level of flexibility and control to the deposition process, enabling the application of materials to dissimilar substrates, or to compensate for the intrinsic typing of components. The model features integrated protective shields to ensure minimal exposure to sputtered material. The inclusion of an end-of-run interrupt and automatic substrate return features also aid in protecting the equipment and its components. The high performance and precision of the system is further improved by the automatic calibration and power balance features, an available digital display, remote access and control capability, and active PFPE protection. PERKIN ELMER 2400-8L is designed for longevity and dependability, with a variety of safety functions built-in, and a robust electronic unit built for reliable operation over extended periods of time. The machine is ideal for a wide range of thin film deposition applications, from small pilot-scale parts to high-volume manufacturing.

There are no reviews yet