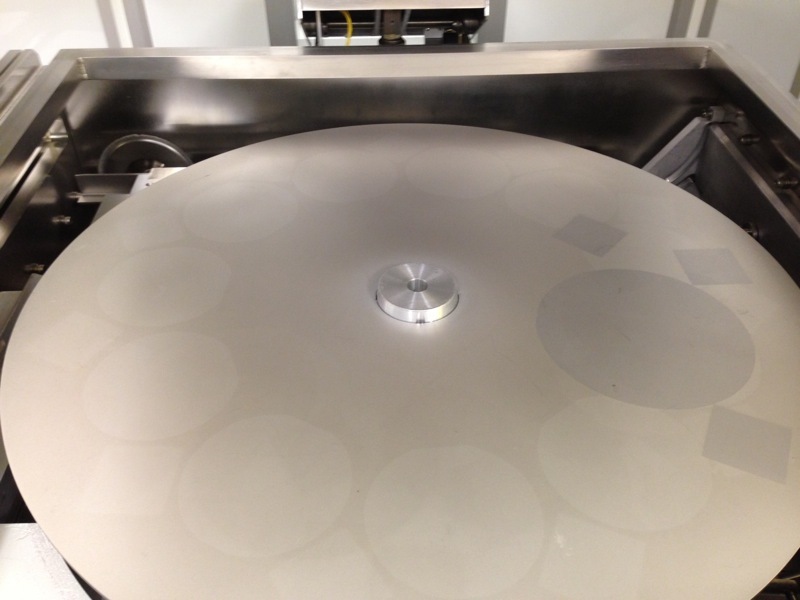

Used PERKIN ELMER 4400 #9026902 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

PERKIN ELMER 4400 is a powerful sputtering equipment widely used in industrial laboratories and production facilities. It is designed for the deposition of thin film layers on large substrates such as semiconductor wafers. The system utilizes several vacuum systems components such as a sputtering chamber, and an electron beam gun to form uniform film layer thickness within a few nanometers. The chamber of the unit consists of bell-jars made of stainless steel with Glomex float optics. These float optics provide efficient trapping of sub-micron particles and a magnetic shield to ensure the homogeneity of the vacuum conditions and reduce impurity contamination. The sputtering chamber is filled with sources of high purity argon or other gas to provide a low pressure atmosphere for the target deposition. At the heart of the sputtering process is the electron beam gun that creates the flux of energetic electrons for bombarding the sputtering target and extraction of film layer material from the target. The electron gun operates using an electronic beam controller and a pre-focus coil for maintaining a focused beam. The gun is adjustable to accommodate different substrate sizes. The source targets are usually made of pure metals or alloys such as titanium, chromium, cobalt, nickel and others during the process. The deposition rate is usually 1-2 nm/s and can be adjusted with respect to the size and shape of the target and the speed of the deposition process. The target rotation speed can also be adjusted to optimize the film deposition rate. The machine also has an overall temperature control that helps to maintain the substrate temperature at a desired level. The tool also includes an in-situ diagnosis asset with tunable lasers and an energy analyzer. This helps to monitor the progress of the film deposition process, ensuring that the desired film layers are being homogeneously deposited on the substrate. The model also provides features such as step coverage and directionality control to ensure the uniformity and integrity of the film layers. In summary, 4400 is a powerful and versatile sputtering equipment designed for the deposition of thin film layers for a variety of applications. Its design ensures a uniform distribution of the deposited film layer, which makes the system an ideal choice for a variety of complex deposition processes.

There are no reviews yet