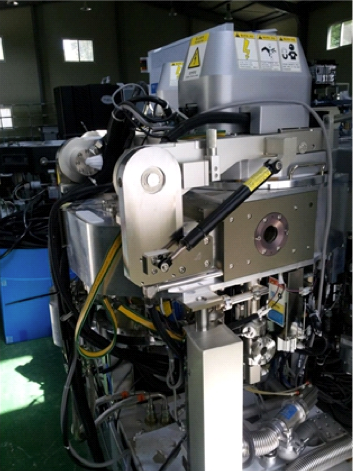

Used ULVAC Ceraus ZX-1000 #195210 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 195210

Wafer Size: 8"

Vintage: 2004

Sputtering system, 8"

Process: 8" metal sputtering

Type: 7 bay (7 module attachable)

Structure:

RF Process module + DC Process

(3) Module

Heat treatment

TM (7 Angle)

(2) L/L

(2) Control rack

Features:

Target changeable

Module changeable

Parts list:

(3) TMP Shimadzu 1002 LM

(3) Controller EI-1002MA

(3) TMP Shimadzu 202 LM

(3) Controller EI-202MA

(3) DC Power Kyosan, 1000V, 50A

(4) Heater Power Hercules, 100V, 25A

(2) UPS Upaco7

Robot module

PC rack

Compressor: HE C30ZR

Cable and dry pump missing

2004 vintage.

ULVAC Ceraus ZX-1000 is a versatile sputtering equipment that provides reliable end-user control for vacuum-based deposition processes. This deposition system is capable of ultra-thin, high-performance coatings of thin films onto materials both organic and inorganic. ULVAC CERAUS ZX 1000 features a robust cast aluminum and ceramic-painted frame, making it highly durable and stable. The design incorporates a full-view chamber with clear observation windows for visibility, and is compliant with both domestic and international safety regulations for use in industrial environments. Adjustable parameters are available for optimized processing conditions, such as process time, pressure, and temperature. The unit's loadlock also facilitates repeatable deposition runs, with rapid evacuation, accurate target storage and a quick-chuck for part unloading and loading. Ceraus ZX-1000 operates using sputtering, a physical vapor deposition (PVD) method which involves accelerated particles released from a cathode target inside the vacuum chamber. These particles are accelerated to a speed that causes collisions with gas molecules, forming a plume of neutral atoms and molecules. The high-velocity sputtered particles react with the substrates to form thin films of desired material. This deposition machine is capable of sputtering of metals, compounds, and circuit components. The adjustable parameters allow for control over the deposition rate and film thickness. CERAUS ZX 1000 also features temperature control, which is essential for high quality depositions and to increase process efficiency. It is capable of quick ramp rate temperature control with a range of 20° celsius to 1000° celsius that can be adjusted over the course of the deposition cycle. This tool also comes with a compressor, clean air dryer, and exhaust pump for exhausting reaction products. In conclusion, ULVAC Ceraus ZX-1000 is a reliable and high-quality sputtering asset with a wide range of adjustable parameters and process control capabilities. It is suitable for use in various PVD applications requiring high-quality, thin film coatings.

There are no reviews yet