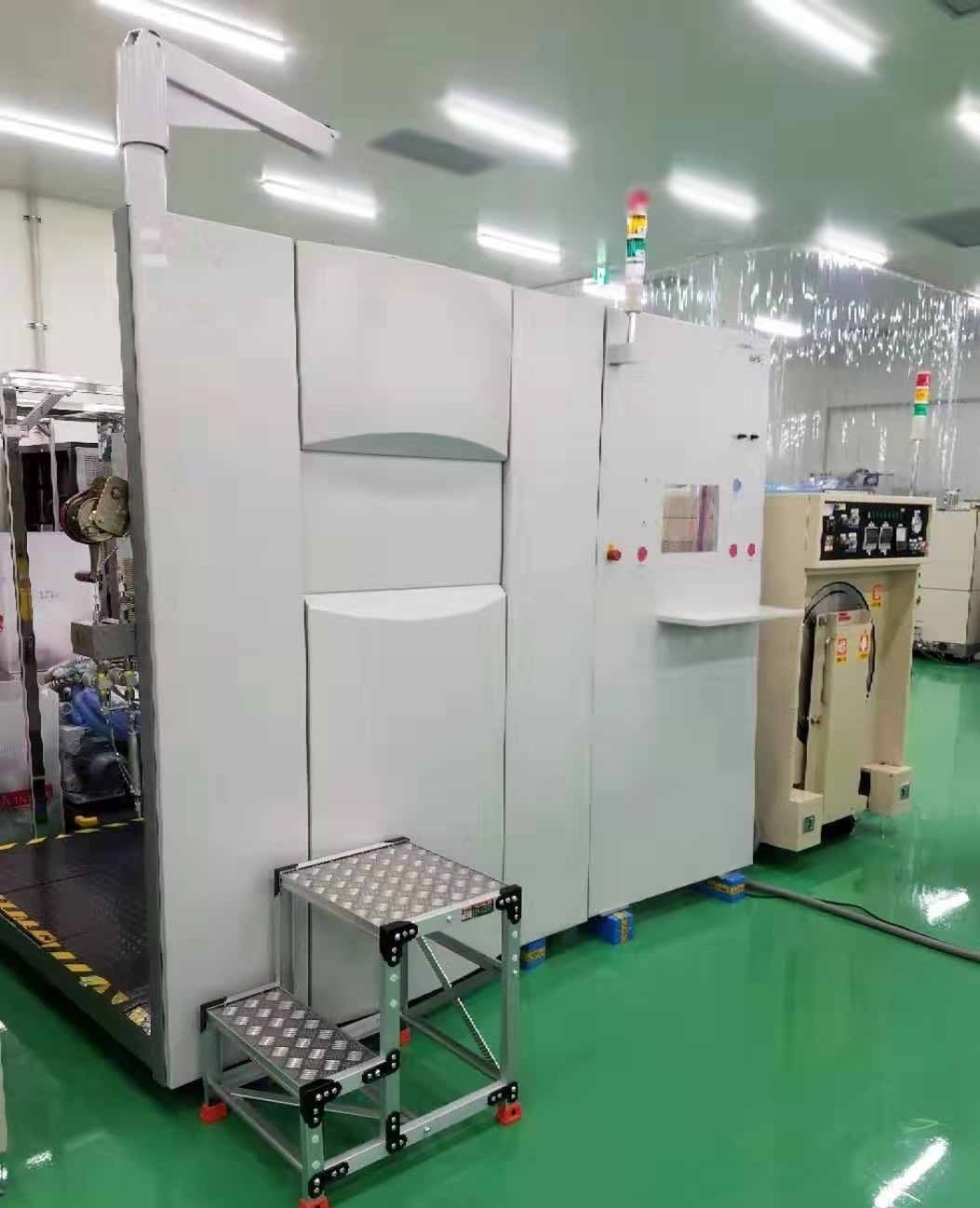

Used UNAXIS / BALZERS LLS EVO #9284249 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

UNAXIS / BALZERS LLS EVO is a sputtering equipment that uses magnetron-sputtering technology to deposit material onto a substrate. This sputter deposition system utilizes specially designed magnetrons with multiple cathode sources and a rotating target wheel to create a uniform and consistent coating. The target is held in place by a rotating wheel and the sputtering is done with a strain-free sputter source. The sputtering process works by using a DC magnetic field and an applied bias voltage to create an electrical arc which produces energetic ions. These ions strike the substrate (workpiece), eroding and removing material that then deposits on the substrate. The eroding material continuously deposits on the substrate, building up a uniform and even layer of the chosen material. Depending on the parameters set such as substrate bias voltage, DC magnetic field strength, and rotor speed, the end result can vary from a thin film or oxide-like layered coating, to a thick coating for protection or wear resistance applications. UNAXIS LLS EVO offers a variety of materials to be deposited, including aluminum, copper, gold, silver, and titanium, as well as customized materials for specific applications. The unit can also be used with a wide variety of substrates, including glass, ceramics, metals, and plastics. The sputtering process is safe, as the substrate does not reach high temperatures and is not subject to any environmental concerns during or after the deposition process. BALZERS LLS EVO is an ideal machine for producing high-end coatings for a variety of industries. The high deposition rate and high precision of the sputter deposition process allow for a faster production rate and more cost-effective solutions. Thanks to the precise control of the magnetrons, the tool produces clean, uniform coatings that are ideal for microelectronics, semiconductors, optics, and other high accuracy applications. Furthermore, the asset can be adjusted to cover surface areas of different shapes and sizes without worrying about width variation or voids, ensuring high consistency and repeatability. As a result, LLS EVO sputtering systems are a cost-effective and reliable alternative for creating coatings for many different applications.

There are no reviews yet