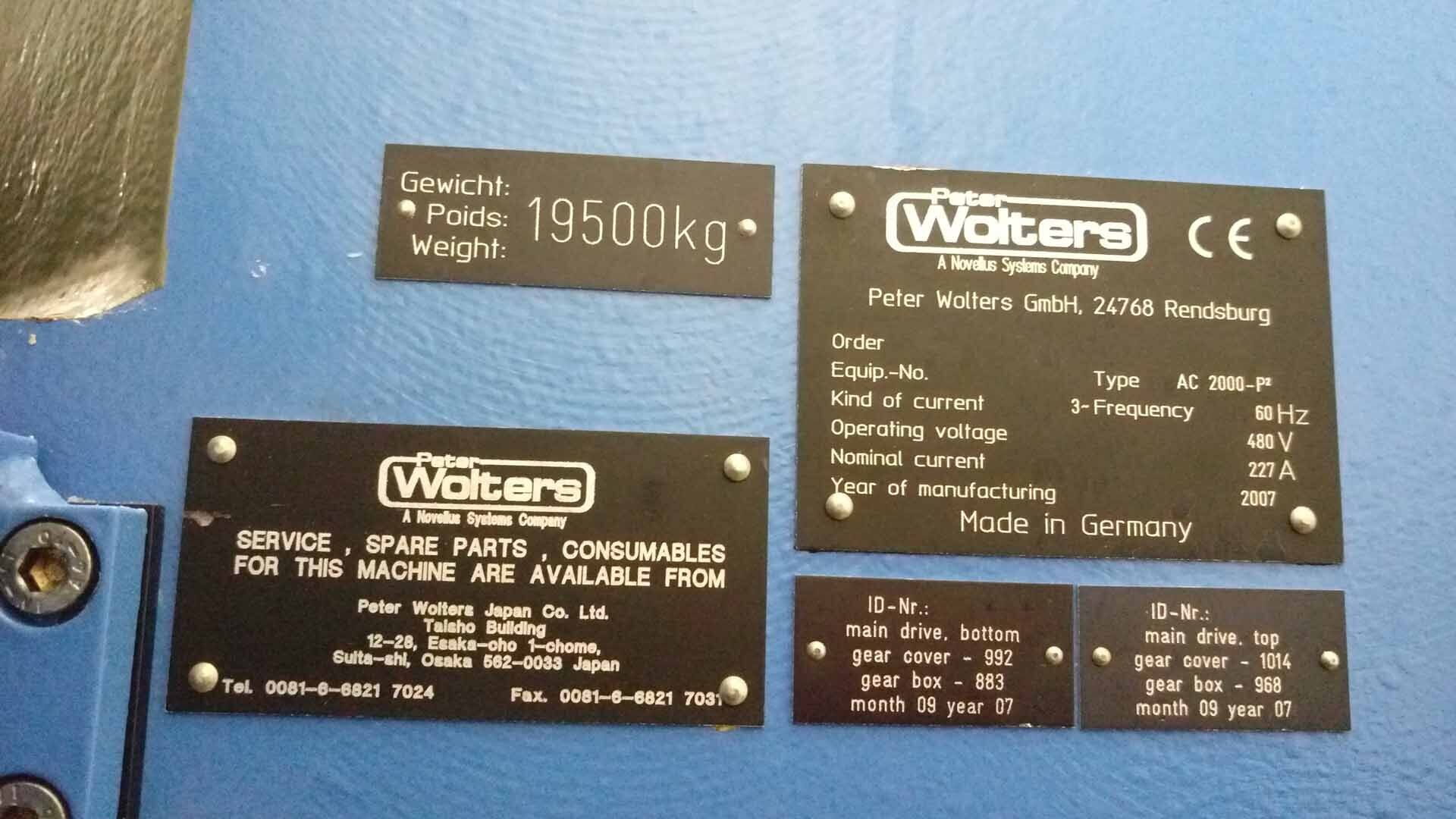

Used PETER WOLTERS / LAPMASTER microLine AC 2000-P2 #9352425 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9352425

Wafer Size: 12"

Vintage: 2007

Double side polishing machine, 12"

Wheel dimensions:

Outer: 1935 mm

Ring width: 686 mm

Thickness: 80 mm

Wheel distance: 190 mm With 80 mm wheel thickness

Pneumatic:

Maximum load pressure: 3500 daN

Compressed air: 6,5 Bar

Electronic equipment:

Servo drives digitally controller

Upper wheel: 46 kW/40 min⁻¹

Lower wheel: 46 kW/40 min⁻¹

Inner workpiece drive: 7,5 kW/min⁻¹

Outer workpiece drive: 7,5 kW/min⁻¹

Hold the drive aggregates for lower working wheel and workpiece drive

Electromechanical height adjustment for outer and inner pin ring

Splash guard pan

Assembly connections for easy access

Pneumatic load control

Interception device

Weighting device

Drives

Working wheels

Safety device

Corrosion resistant design

Electric switch cabinet (Air cooled)

CNC Controller

Operating panel

Polishing media connection and metering

Slurry distribution system

Polishing media collecting channel

Tool kit

Basical range of CNC Control S7-400 With visualization

Pressure control via proportional valve and pressure sensor

Display of the actual pressure value

13-Pressure ranges

Variable speed of rotation change in each pressure range of each drive

Variable change of rotation direction

Automatic swiveling in / out

5-Conditioning program with recorded inception heights

Alternative list for selective programming functions:

Swiveling device

Starting of the drives

Feeding of the polishing media

Wet mode

0020: Brush program

0030: Cooling water temperature monitoring

0040: Rinsing and spraying device (Chemical polishing)

0050: Spraying device

0060: Levelling device for horizontal adjustment of the upper working wheel

0070: Epicyclic work holder drive system

0080: (2) Polishing wheels

0090: Back up

Options:

0100: Power backup

0110: Polishing compound connection

0120: Cable identification

0130: Mixing block

0140: Taiwan electrics

Electrics: 460 V

UPS: 230 V

0150: Packing

0160: Commissioning

0170: Status light

0180: Loading counter

0190: Second hand operation station

0200: Shower guns for DI- Water

0210: (2) Heating / Cooling aggregate (WRK) 12760 W

0220: Heating / Cooling aggregate Heating possibility up to 55°C

0230: Fittings for cooling water circulation system with refrigeration unit

0240: 6-Step polishing program

0260: Fiberglas cable

0270: Separate drive security

0290: Signal tower with LED

0300: Indication of signal tower

0310: Upgrades

0320: 80-Polishing feed holes

0330: Anti-syphoning package

0340: Measuring device (Flatness)

0350: Distance block set

0360: Steel straight edge, 2000-0 mm

0370: Additional cable length

0380: Engineering costs

0390: PDR System

Power supply: 400 V + 6%-10% (Acc. DIN IEC 38)

Frequency: 50 Hz

Control voltage: 203 V / 24 VDC

2007 vintage.

LAPMASTER AC 2000-P2 is a wafer grinding, lapping, and polishing equipment for semiconductor wafers. It is a precision instrument with a computerized controller, a modular error-free spindle drive, and a wide range of high-quality abrasive materials and quick-change-over mounted on an industrial grade granite base. The system is designed to handle 200-300 mm wafer lapping and grinding with the highest accuracy and repeatability. The AC 2000-P2 features a two-stage lapping and polishing process. Each stage is divided into two parts: the first stage consists of a mounting station, a wafer clamping plate, and a robust lapping wheel. The second stage uses a different lapping wheel and features a polishing pad holder and a coarse-to-fine progression of abrasive agents. Both stages include a variable speed adjustment, allowing the operator to increase or decrease the speed as needed. The AC 2000-P2 also features a computerized controller, which provides the operator with detailed data, including run time, process settings, automatic shutoff, and machine status indicators. The controller is extremely flexible and can accept a wide range of input choice options, such as manual, semi-automatic and fully automatic mode. The unit also offers adjustable parameters like pressure, slip, and vibration limit regulation to ensure the highest process accuracy. The machine also has an integrated dust removal tool. Air blades sweep away generated abrasive dust while disposing it external to the machine. The dust collection meshes also have adjustable settings to meet the most stringent particle requirements. PETER WOLTERS AC 2000-P2 is equipped with a modular error-free spindle drive that offers high-precision operation. This sophisticated design, combined with the principles of ergonomics and AC motor technology, provides a reliable and safe operation. The asset also includes a variety of optional modules, such as an air-unit for wafer clamping and overpressure-control, as well as a high-accuracy vibration protection model. These features make PETER WOLTERS / LAPMASTER AC 2000-P2 an ideal machine for the mass production of high-precision wafers. Its precision engineering and flexibility offer a true 'all-in-one' equipment, capable of lapping, polishing, air-blowing, and any other refinements required in the production process. The system's controller gives the operator full control over the process, allowing for superior process quality. The AC 2000-P2 is an ideal choice for producers looking for a reliable unit for the manufacturing of semiconductor wafers.

There are no reviews yet