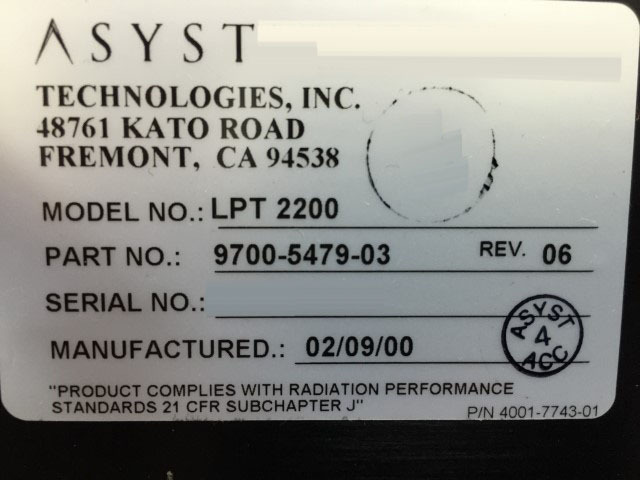

Used ASYST LPT 2200 #9111899 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ASYST LPT 2200 is a wafer handler designed for use in manual to semi-automatic wafer-handling operations. It is designed to provide fast and efficient wafer access for through-hole, surface-mount and area array components. It is capable of working with all types of wafer configurations, such as 2", 2.5" and 3" diameter. It is a fully automated equipment with a wide range of features that make it suitable for a variety of wafer-handling applications. ASYST LPT2200 features a main frame body with a handle which provides easy mobility of the system. The unit includes a variety of interchangeable and user configurable components, such as a cassette loader, semiconductor device and pick-and-place robot, wafer chuck and wafer carriers, wafer ID and finger print reader, and a vision machine. The main frame also features a lockable drawer and a selection of up to eight vacuum lamps. The cassette loader allows for storing up to 16 wafers at any given time and can perform a variety of tasks, such as loading and unloading wafers, alignment and loading of the chuck and carriers, automated check for physical defects and other tests. The robotic pick-and-place offers highly reliable handling of the wafers and components, and is capable of performing up to 250 simultaneous pick-and-place moves per second. The wafer chuck and carriers allow for secure and reliable handling of wafers and components, and have integrated protective covers to prevent contamination. The wafer ID and fingerprint reader allows the tool to quickly detect any incorrect components, who placed them and which wafer they were placed on. This helps ensure accuracy and traceability. The integrated vision asset offers intelligent inspection capability to assist in the inspection, upload and detect quality issues. LPT 2200 is an ideal model for handling of highly sensitive components as it is designed to maximize equipment uptime, minimize maintenance costs and improve productivity. The equipment also has a versatile and secure control system, allowing for centralized control and automation of all processes. Additionally, the unit is designed for ease of use and features a comprehensive set of safety features, such as automatic shut-off, protective covers and secure access. This makes it a reliable and safe machine for use in production environments.

There are no reviews yet