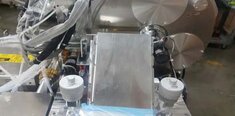

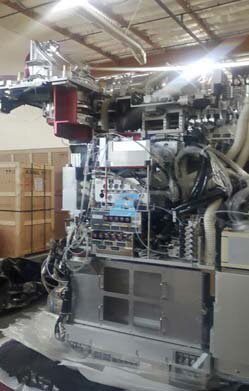

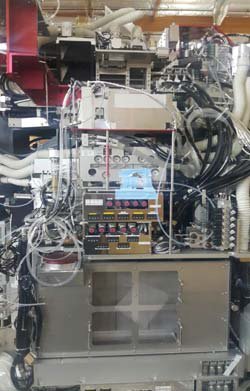

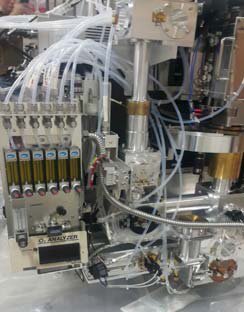

Used NIKON NSR S306C #9379645 for sale

URL successfully copied!

Tap to zoom

ID: 9379645

Wafer Size: 8"

Vintage: 2003

Scanner, 8"

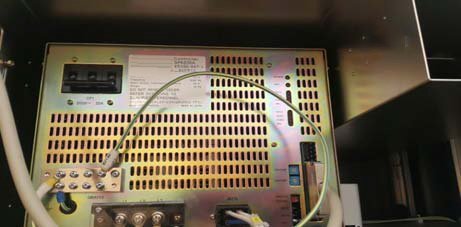

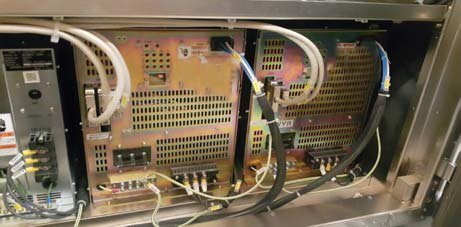

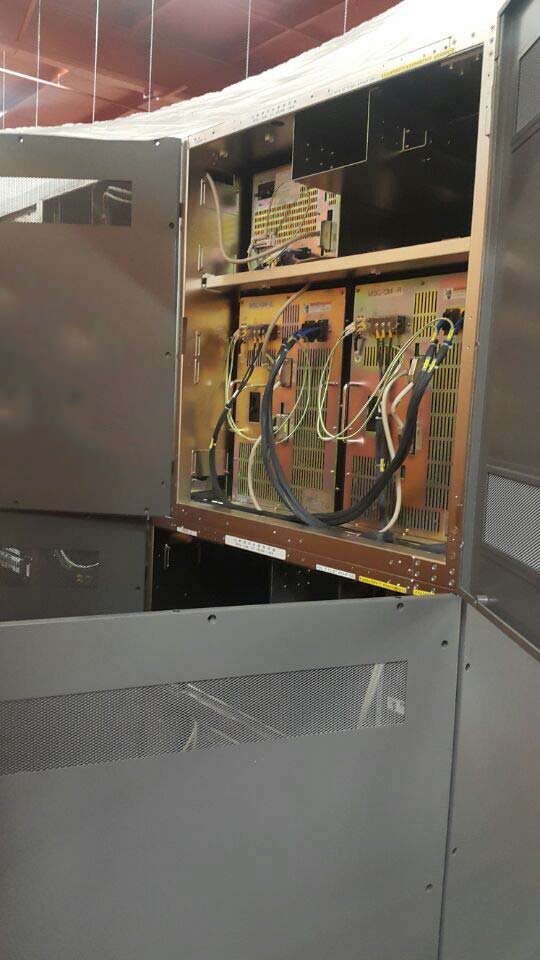

Main system: MCSV

Operating system: Open VMS / Windows NT / Linux

Hard Disk Drive (HDD)

Floppy Disk Drive (FDD) / CD Drive

PPD

Unit system:

Wafer stage: Air

Chuck type: Pin chuck, 8"

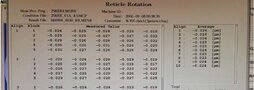

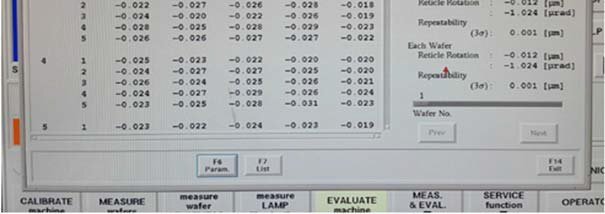

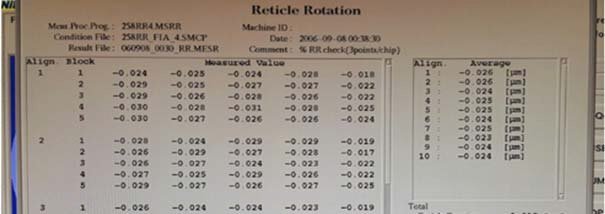

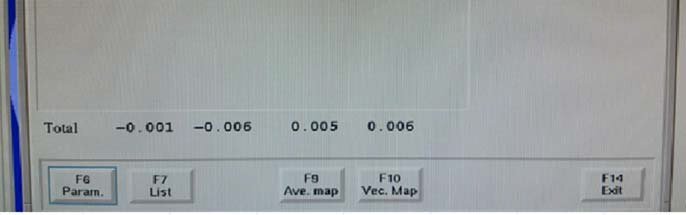

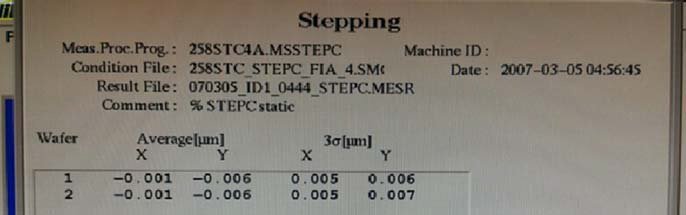

Reticle alignment: SRA, VRA

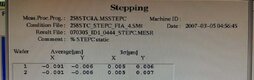

Wafer alignment: LSA, FIA

BMU: Normal type

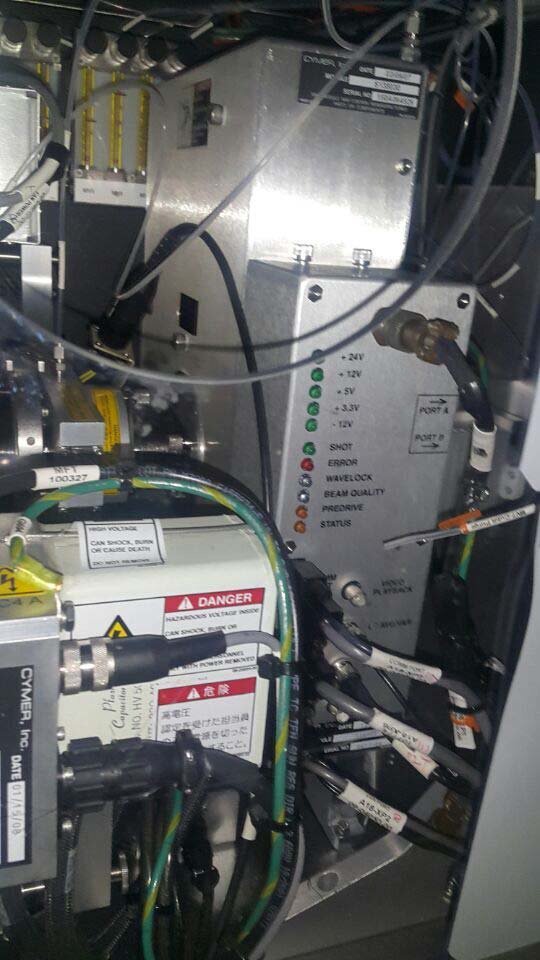

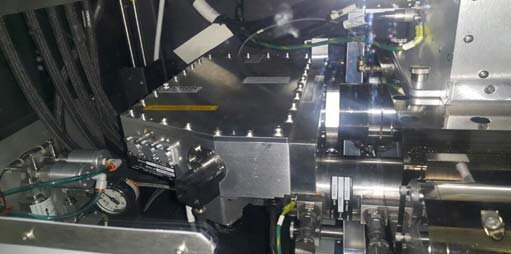

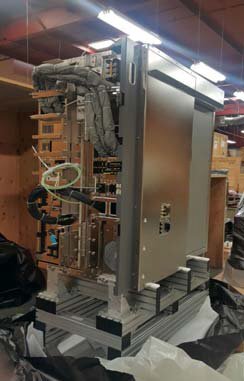

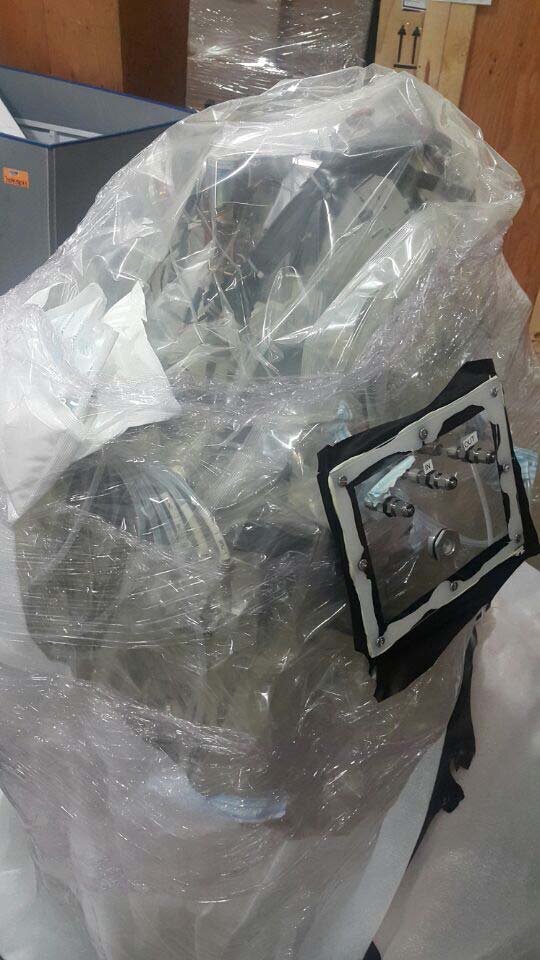

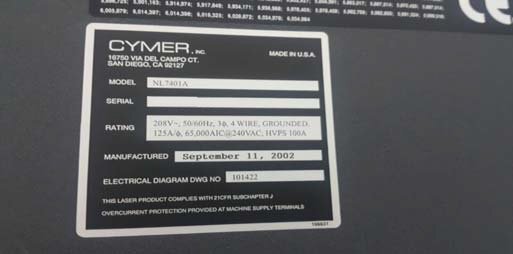

KRF Laser: CYMER Laser 7401

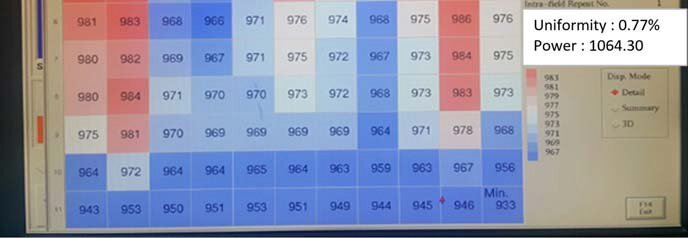

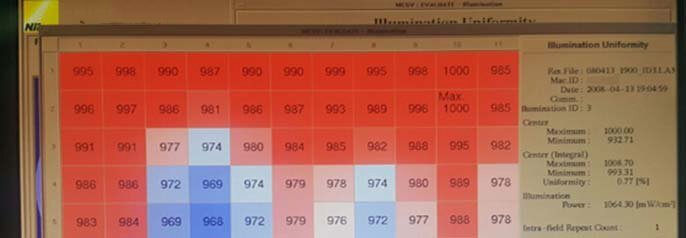

Auto focus: Multi

Chamber type: Sendai

Model no: S37

Wafer loader:

Loader type: Type 4

Wafer type: Notch

Flat zone position: 6 o'clock

In-Line: Left

Cassette: Right

Control rack position: Left

Reticle loader:

Reticle size, 6"

Library: 20-Slots

Bar code system:

No case

Reticle

2003 vintage.

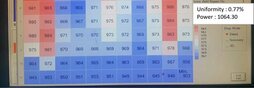

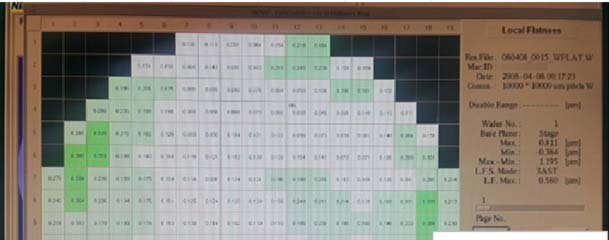

NIKON NSR S306C is a high-performance wafer stepper used for photolithography in semiconductor manufacturing processes. It utilizes advanced optics and high-precision motion control systems for accurate aligning of a wafer in order to pattern various circuit levels onto the surface. NIKON NSR-S306C's 6" round base production wafer consists of two independent sensor heads, which allow for higher throughput and greater flexibility. The wafer stepper is capable of inspecting multiple different levels, including resist and ground layers, as well as inspection of cuts and adhesion layers. Additionally, the equipment can perform scan magnifications of 10x and 20x. NSR S306C has a high-speed auto-focus system that utilizes a liquid lens for fast and accurate alignment. Additionally, the stepper features a 12 station lens changer with optimized algorithms for automatic lens changing and wafer loading. This unit enables high-speed scanning and reduces cycle times of the production process. NSR-S306C also features advanced lighting sources that allow for optimal exposure for advanced patterning processes. The adjustable exposure level ensures higher accuracy and improved coverage in different exposure zones. NIKON NSR S306C also features advanced data acquisition and control systems. This enables automatic exposure days and results logging, for optimization of the exposure process. In terms of maintenance, the machine has an easy to use automated maintenance tool with built-in test patterns which helps minimize downtime and extend the lifespan of the wafer stepper. Furthermore, NIKON NSR-S306C is also an environmentally friendly asset as its low power consumption helps to reduce CO2 and other emissions. Overall, NSR S306C is a high-performance wafer stepper which offers high accuracy and throughput, reducing model cycle times while maintaining optimal quality of the process. Its advanced optics, high-precision motion control systems, lighting sources, and maintenance equipment provide excellent results during semiconductor manufacturing processes.

There are no reviews yet