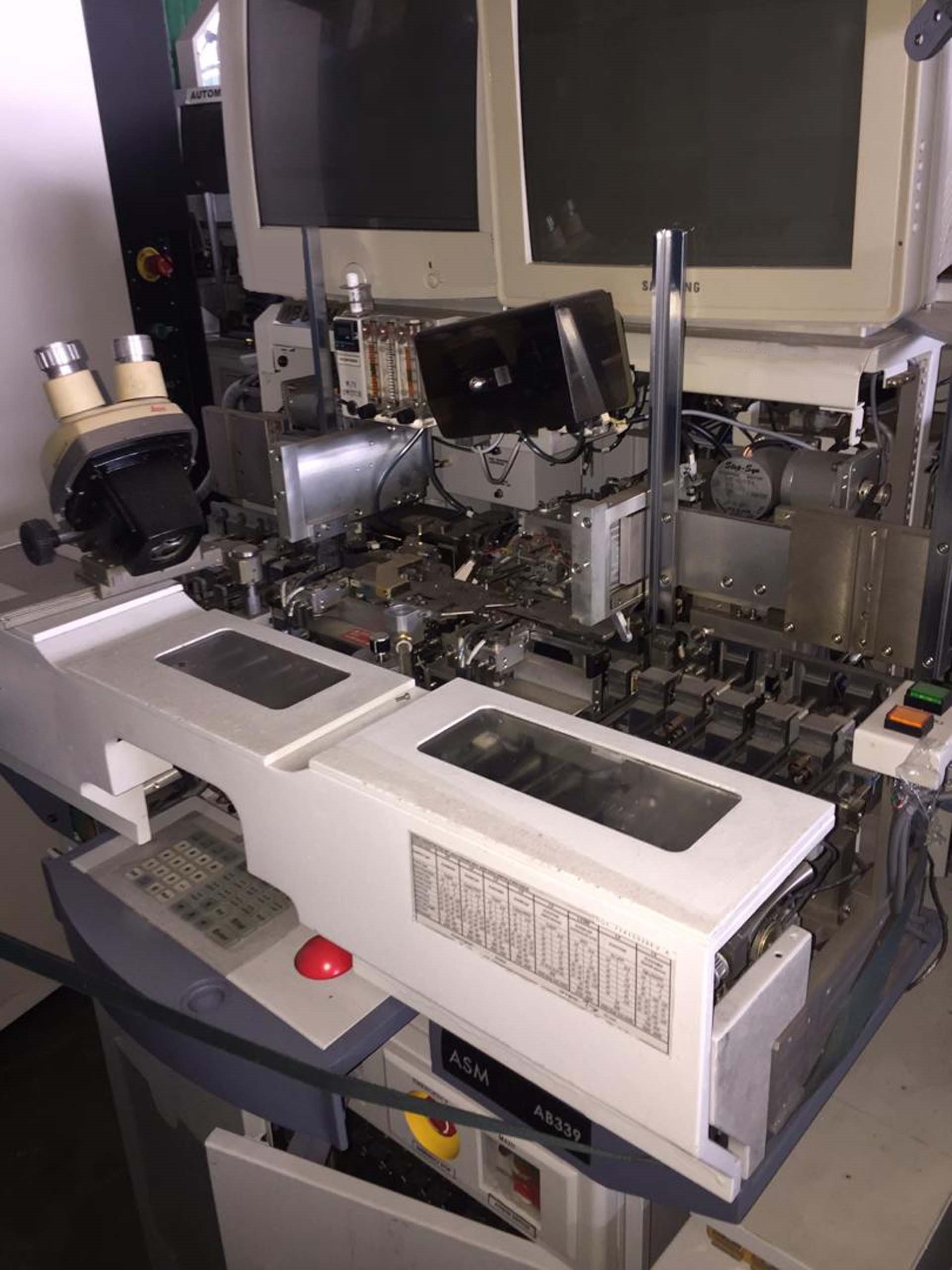

Used ASM AB 339 #9032255 for sale

URL successfully copied!

Tap to zoom

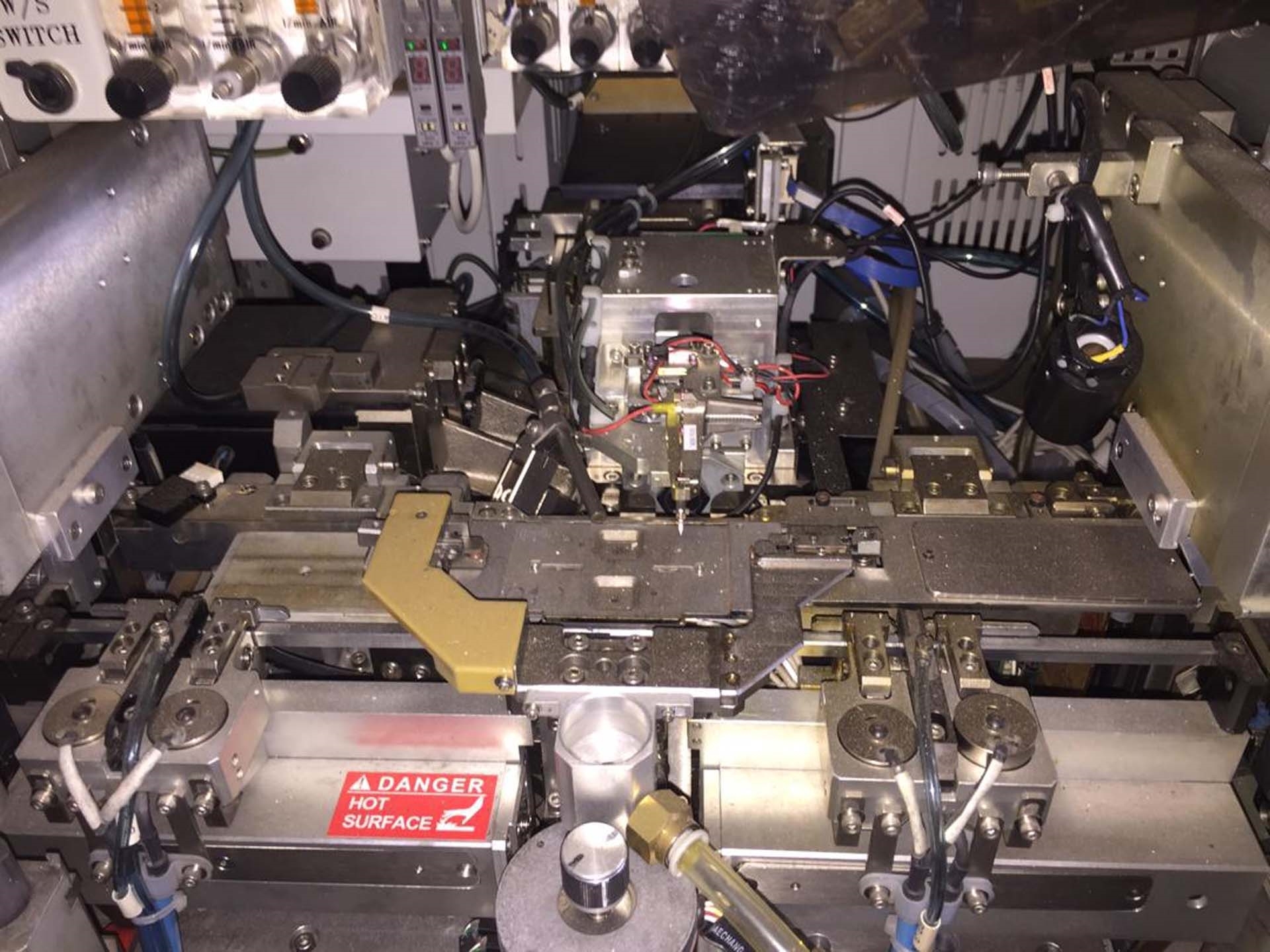

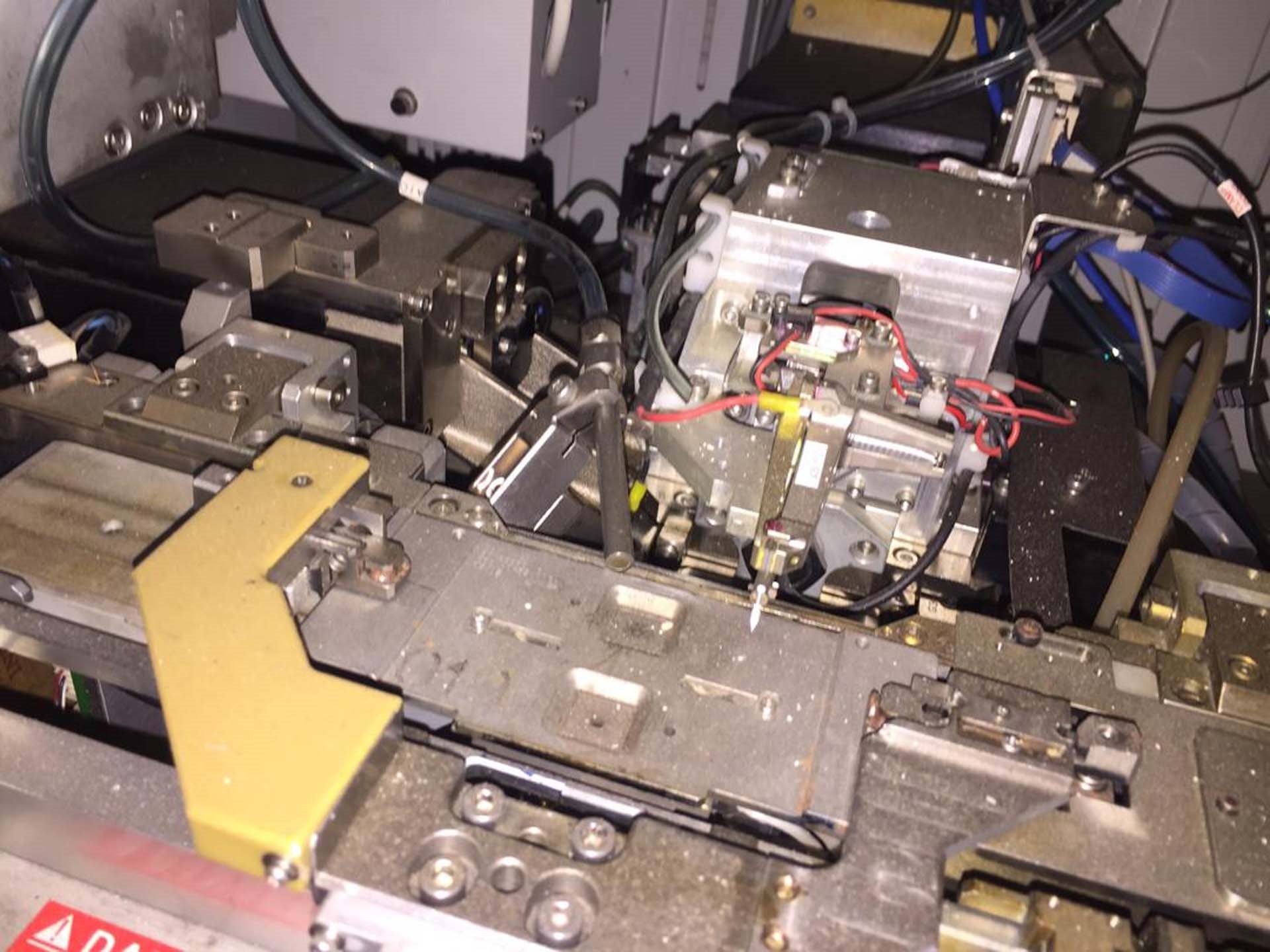

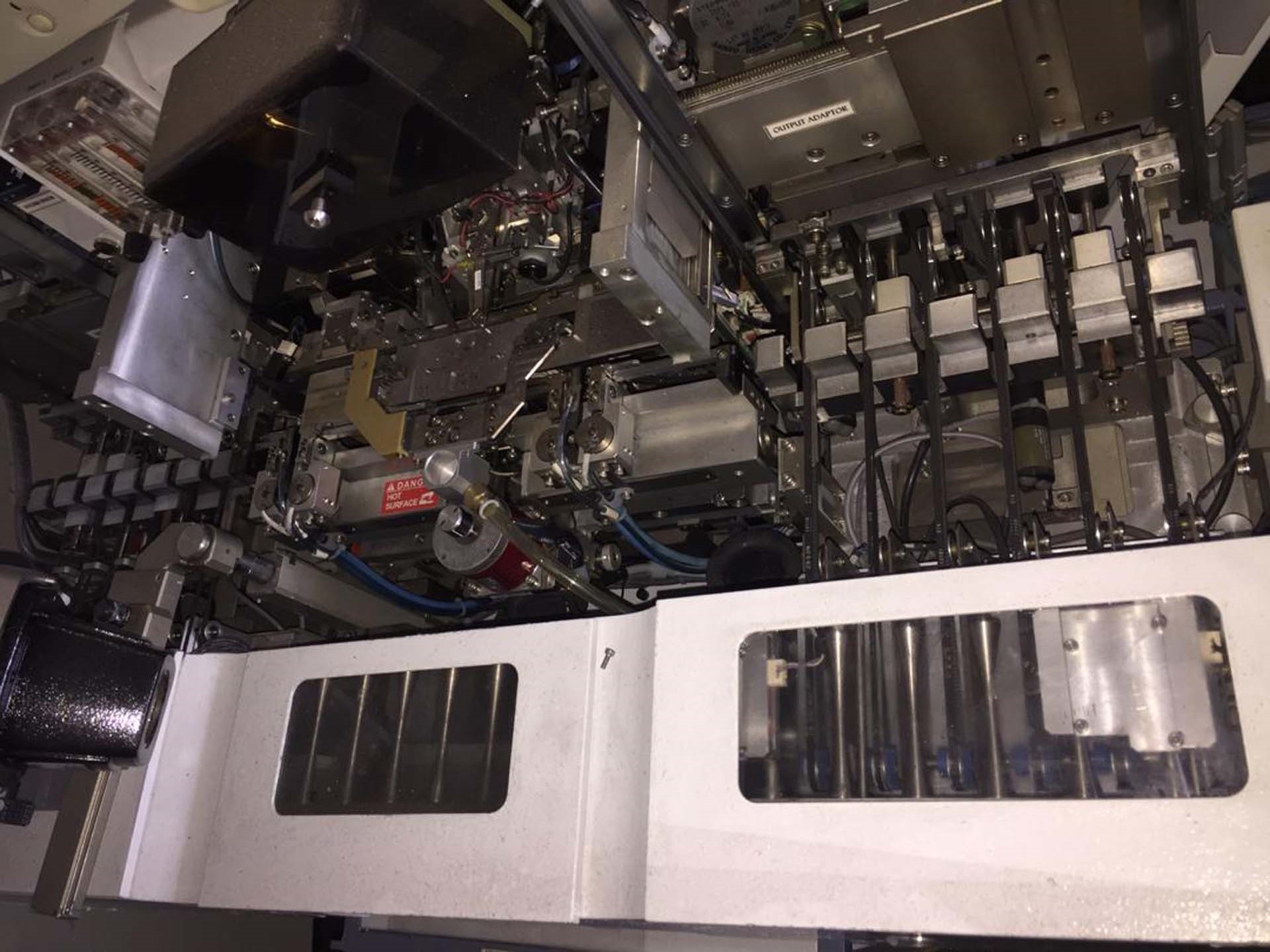

ASM AB 339 is an advanced, automated wire bonder for a variety of industrial operations and components assembly. It is capable of accurately bonding fine-pitch connectors with wire sizes ranging from 0.50mm to 0.71mm. It has a two-head wire bonder with full control of the height, speed and accuracy of the joining process. The machine is equipped with advanced laser-imaging technology for real-time, accurate placement of wires. The advanced motion control equipment provides precise speed, acceleration and force control for the bonding process. This ensures perfect bonding and accuracy of the wire positions. ASM AB339 utilizes a slim-profile head design, which allows the user to easily reach into tight spaces or tightly-packed components. The adjustable system permits the user to directly input data regarding the wire length, width and thickness to accurately bond any size or shape of wire. It is also equipped with an auto-gap compensation unit, which automatically adjusts the gap in the bonding wires based on their size, shape and location in the assembly. This ensures precise bonding for optimal performance and control. AB 339 is designed with ergonomic features to reduce operator fatigue and increase safety. The intuitive user interface has all the necessary controls conveniently located at the front, enabling easy access for the operator. The machine is also equipped with an integrated safety tool to help reduce the risk of operator injury. The asset's advanced wire bonding technology processes a variety of metals, including metals like aluminum, copper, tin, silver and gold. It is also equipped with an auto-welding process for advanced joint formation and higher yields. This model also supports various bonding methods, including ultrasonic bonding, thermo-stacking and surface mounted device. This ensures reliable wire bonding and long-term performance. In addition, the equipment is equipped with several data capture options, such as wireless remote station, barcode scanning and PC communication, for quick and efficient access to production information.

There are no reviews yet