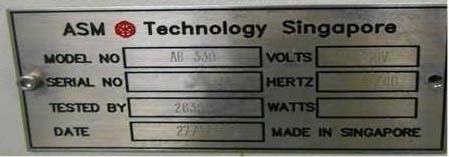

Used ASM AB 339 #9257826 for sale

URL successfully copied!

Tap to zoom

ASM AB 339 is a high-performance automatic adhesive bonder designed to provide consistently reliable and accurate automated operation for a wide variety of applications. The bonder is a modular equipment consisting of three different modules: a control unit, a dispense needle, and a liquid-applying needle. The control unit provides the user with intuitive programming and precise control of the bonded parameters. The dispense needle module provides precise deposition of the bonding adhesive on the substrate while the liquid-applying needle module provides rapid and accurate application of the liquid onto the substrate. The bonder has a compact, ergonomic design and offers a variety of options and accessories to meet the specific needs of the user. The control unit provides programming of the bonding parameters such as the speed of the bonding process, the dispensing nozzle deposition speed, and the amount of material to be deposited. It also allows the user to set a combination of parameters to optimize the bonding process. The bonder has a range of powered engines to provide different levels of speed and force for the bonding process. The bonder has an automatic and manual mode of operation. In the manual mode, the operator can manually monitor the process and adjust the settings as required. In the automatic mode, the parameters are set and the bonder goes into the bonding process with a repeatable and consistent velocity. The bonder also has an integrated diagnostics system to monitor and evaluate the process parameters. This allows the operator to assess the bond performance effectively and take corrective measures to improve the process. The bonder also has a number of peripheral sensors to monitor the quality of the bonding process and provide feedback to the operator. In addition to providing a reliable and accurate bonder, ASM AB339 offers its users a range of accessories for convenience. These include a self-tapping tool for securing the components in place, a support unit to hold components in place during the bonding process, and a machine of removable plates and fixtures to allow easy cleaning and maintenance. The bonder also offers a range of safety features to ensure safe operation of the bonder. These include a safety cover over the needle tip to avoid accidental contact, a single-push button safety override for electrical shocks, and a tilt sensor to prevent operation if the bonder is moved or tilted at an angle greater than allowed.

There are no reviews yet