Used ASM AB 520A #9303883 for sale

URL successfully copied!

Tap to zoom

ID: 9303883

Vintage: 2004

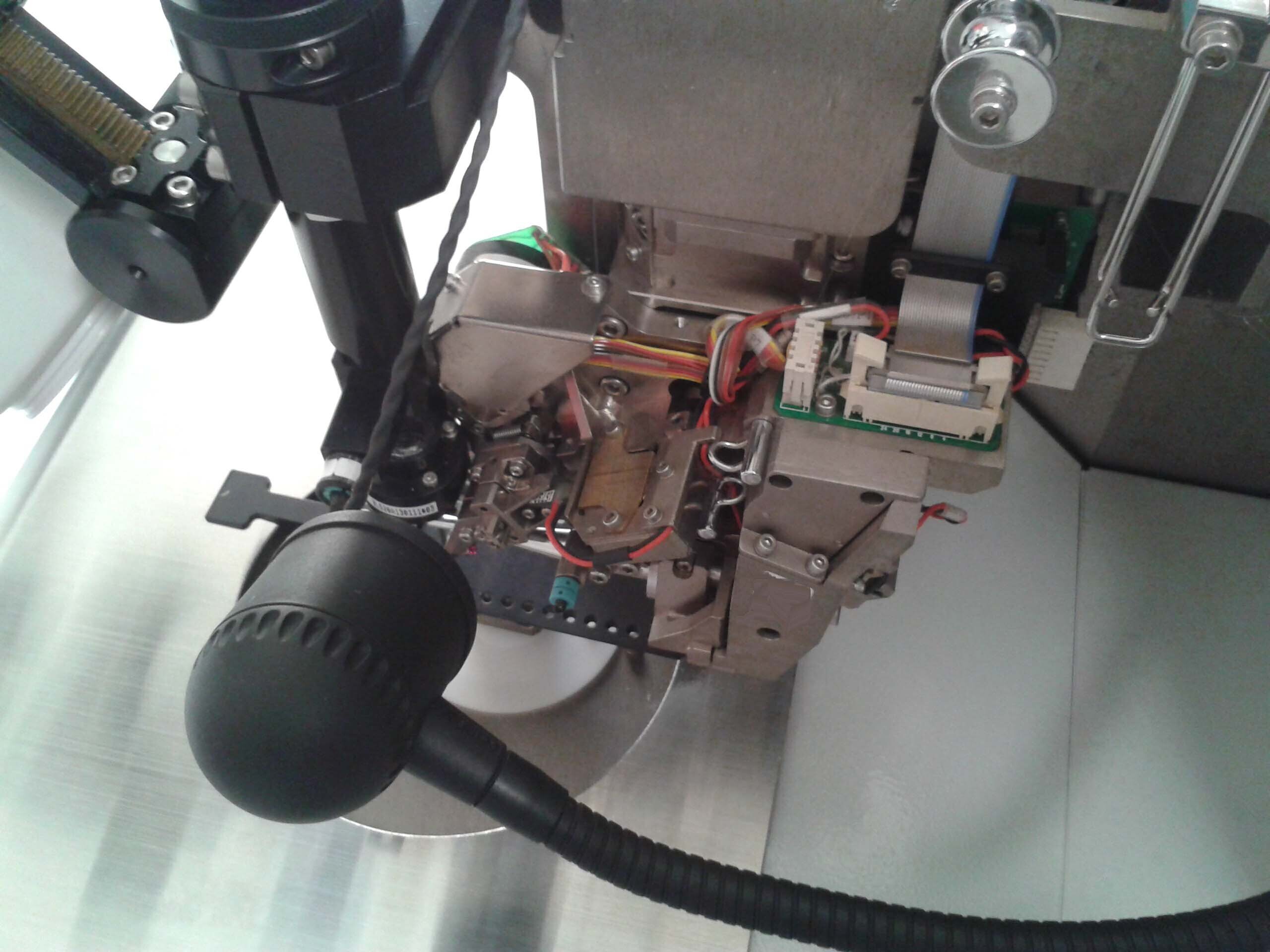

Wedge bonder

01-18557 Service kit:

Part number / Description

01-54225 / Service kit common parts (Rotary chuck)

88-00210 / Wedge GAISER 2130-1820-L-ELBR-W=0.003

01-18557 Service kit:

Part number / Description

00-00750 / Plastic box

01-18561 / Hook mass base assy (50 g)

26-16589 / Front mirror (35-01082)

26-40760 / Additional mass (50 g)

26-40882 / Setup gauge

26-41372 / Height and gap gauge

26-E08412 / VCM Gap gauge

93-83012 / Allen key .035" L-Wrench

Power supply: 220/110V, 1A, 50/60Hz

2004 vintage.

ASM AB 520A is an automated wafer bonder equipment designed for prototype to high-volume production of microsystems and components. It provides users with the capability to bond automatically substrates with repeatable and reliable accuracy, down to 10 microns. This advanced bonder has a customizable graphical interface for user convenience, and a split screen display to simplifying programming. AB 520A consists of a production stage, which contains the bonding head, and a control console that enables process control and inspection of the substrate and die. The bonder is equipped with a highly flexible bonding head which offers both manual and automatic modes. Automatic mode allows the head to be easily adjusted and optimized for specific tasks and applications. This head provides repeatable accurate parallelism to enable bonding of substrates of varying widths and shapes. The bonder is also equipped with a vacuum chuck that enables efficient substrate handling. The vacuum chuck automatically moves the substrate for mounting on the die, and clamps it in place prior to bonding. It also allows for different types of bonding techniques such as thermoplastic, anisotropic, reflow, and anodic bonding. The bonder is also capable of performing advanced features such as multilayer wafer bonding, die-level metallization, moving die position, and inspecting resulting bonds. ASM AB 520A also provides a built-in fusion feature that allows the user to fuse two chips together. This fusion can be used in applications such as hermetic sealing of chips, and wafer-level packaging. It also offers dual bond-head capability for precise die-detect and inspection. The bond-head is capable of second-level wirebonding which is ideal for assembly processes that require more than one wirebond. The system is also equipped with a vision unit, allowing it to accurately inspect the substrates for defects. The vision machine supports several advanced features such as defect detection, die-fault isolation, and die-edge finding. Additionally, AB 520A provides dynamic process control capability to ensure optimal efficiency and repeatability of your bonding process. ASM AB 520A offers efficient wafer bonding and multilayer packaging for microsystems development and production needs. It provides high accuracy and repeatability, with versatile control capabilities and built-in fusion and vision systems. The tool is designed to support small-scale manufacturing and ideal for prototyping to high-volume production.

There are no reviews yet