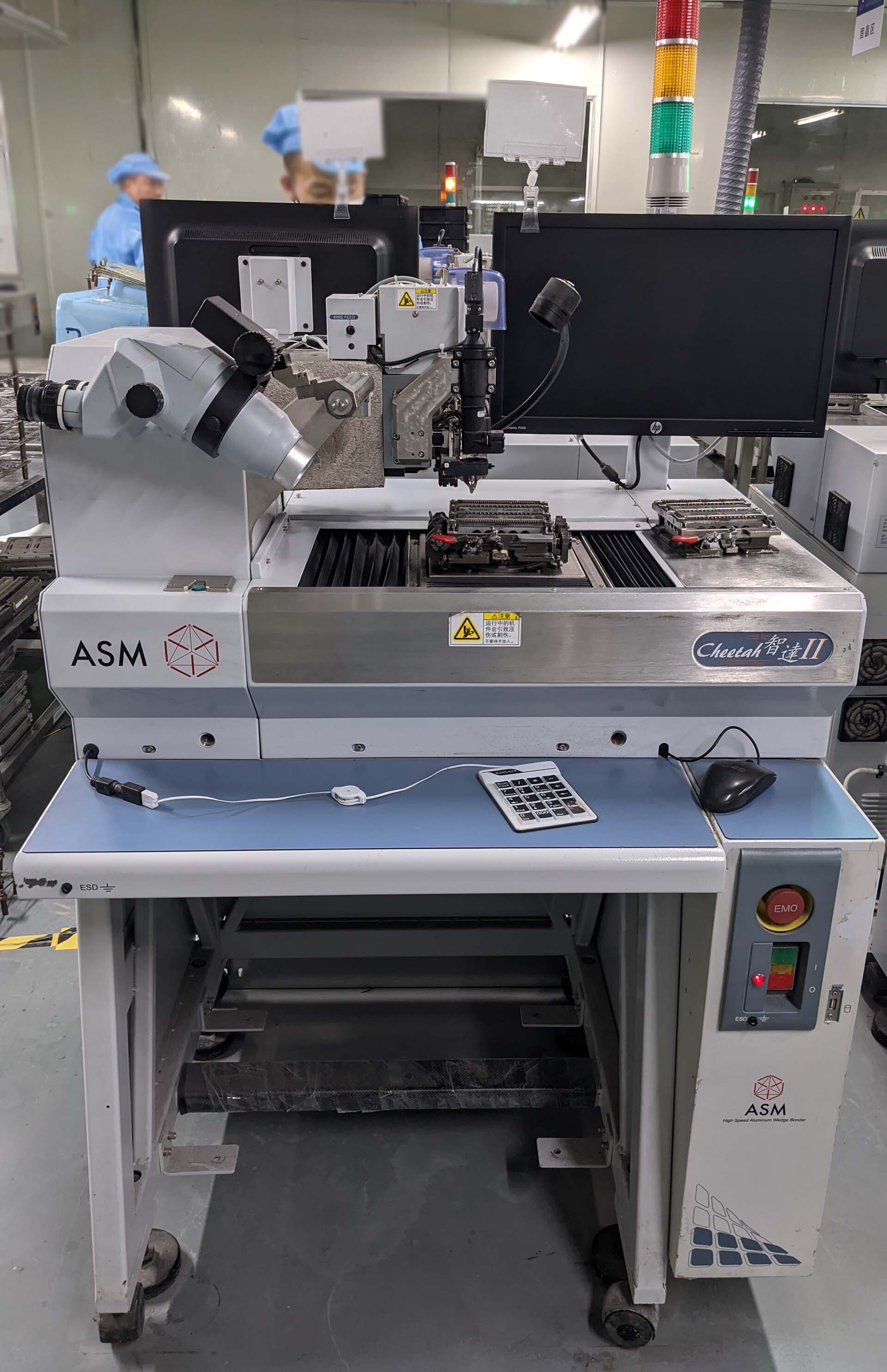

Used ASM Cheetah II #293634223 for sale

URL successfully copied!

Tap to zoom

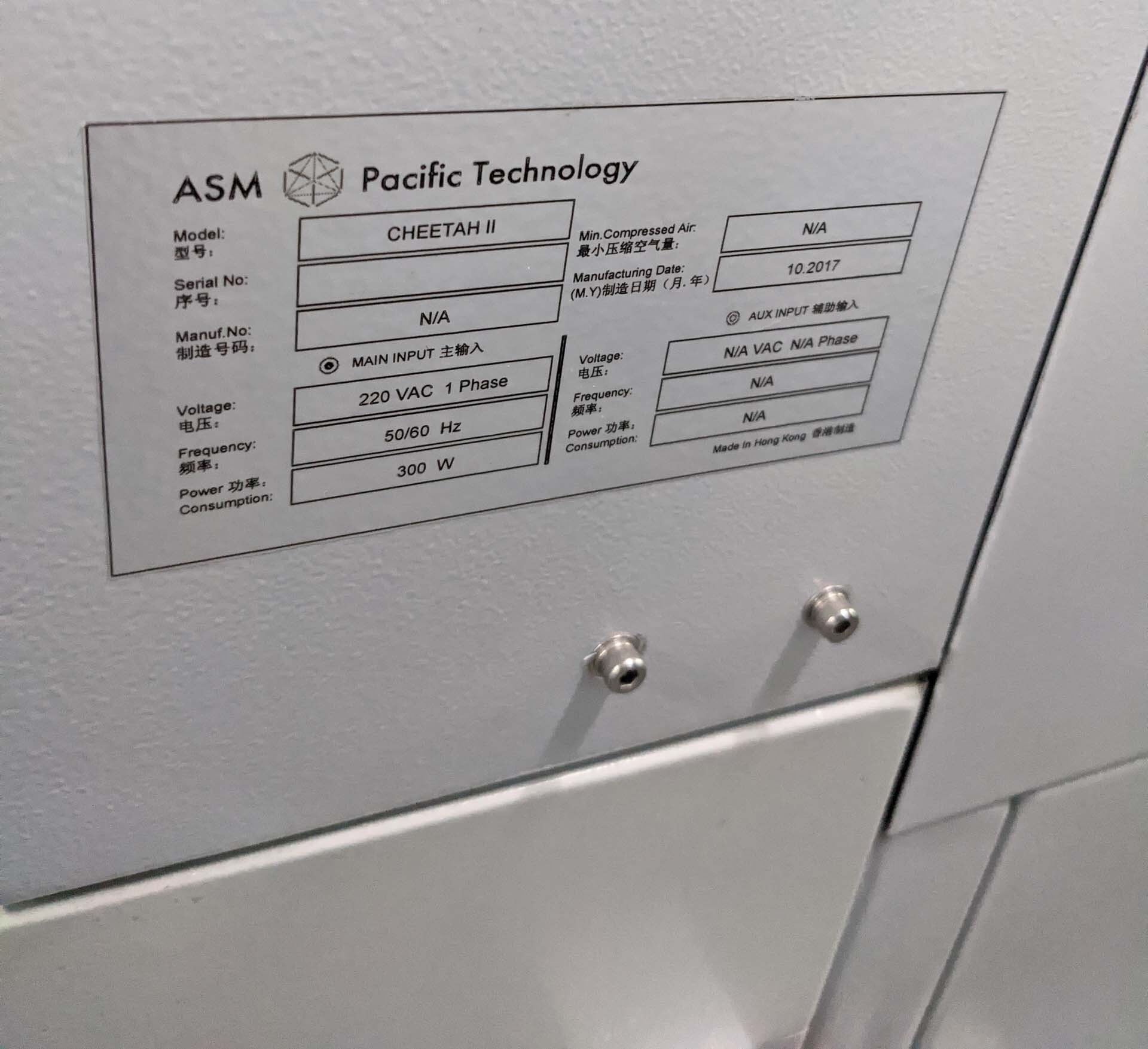

ASM Cheetah II is a four-head semi-automated die bonder designed for high-volume production of die-attached substrates. This apparatus is capable of both horizontal and vertical placement of components and offers a range of bonding techniques, including gold (Au) ball, aluminum (Al) wedge, and ribbon (Rib) wire bond. This allows for high-throughput and uniform bonding of a variety of die/substrate materials. Cheetah II die bonder is capable of recognizing and correcting for placement misalignments before and after bonding, as well as for verifying that the bond has been successfully completed. It comes with a fully integrated vision system integrated into the bond head, providing real-time feedback to ensure all bonds have been successful. ASM Cheetah II die bonder also includes an intuitive graphical user interface (GUI), making it user-friendly to operators and engineers of all skill levels. Cheetah II is equipped with programmable parameters allowing for a wider range of substrates, die sizes, and bond designs to be accurately self-aligned. ASM Cheetah II also features a heated stage as a standard option, making it suitable for a wide variety of substrates including polyimide, teflon, PET, and ceramics. Additionally, Cheetah II's optional USB port allows users to store up to 4GB of bond recipes, so that they can easily be repeated without having to reprogram the machine again. ASM Cheetah II is designed to be robust, reliable, safe, and flexible for a number of production processes. Cheetah II can be used for precision die-attach processes, as well as a variety of other assembly processes. Using this die bonder, engineers and manufacturers can increase the speed, accuracy, and overall quality of their assembly process. With its high throughput process capability, advanced full-field vision system, and user-friendly design, ASM Cheetah II is a perfect choice for production lines in need of reliable die-attach processes.

There are no reviews yet