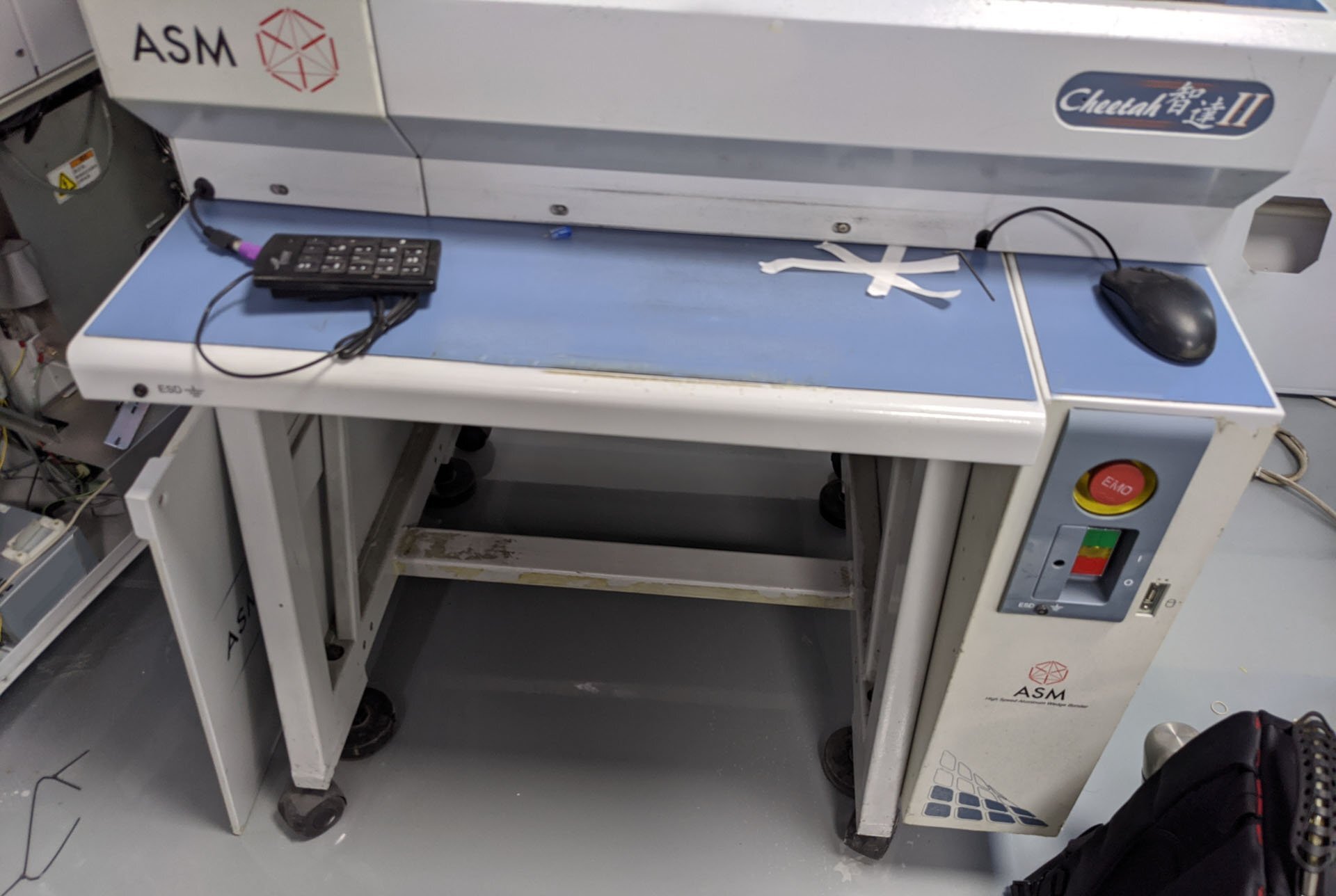

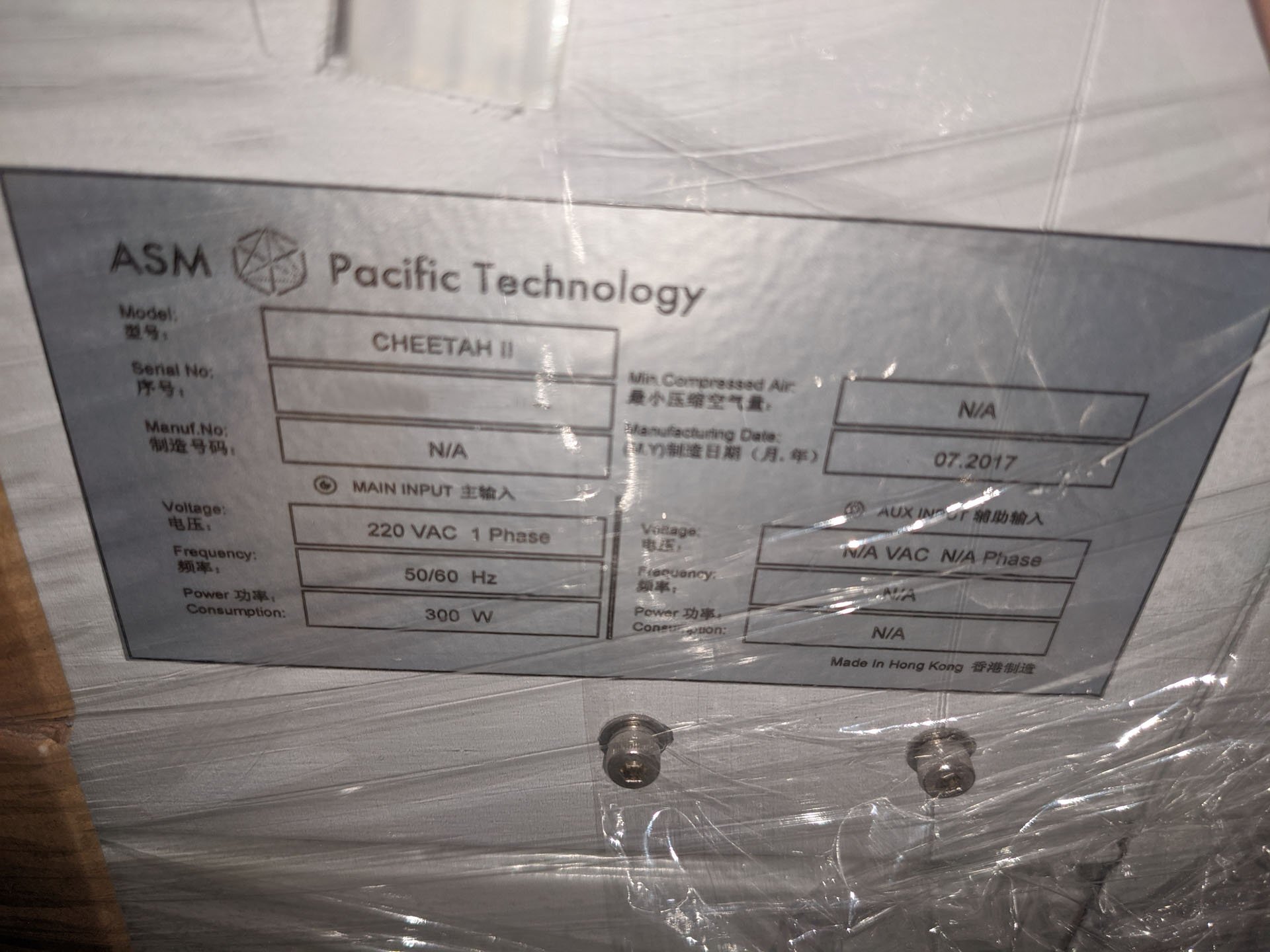

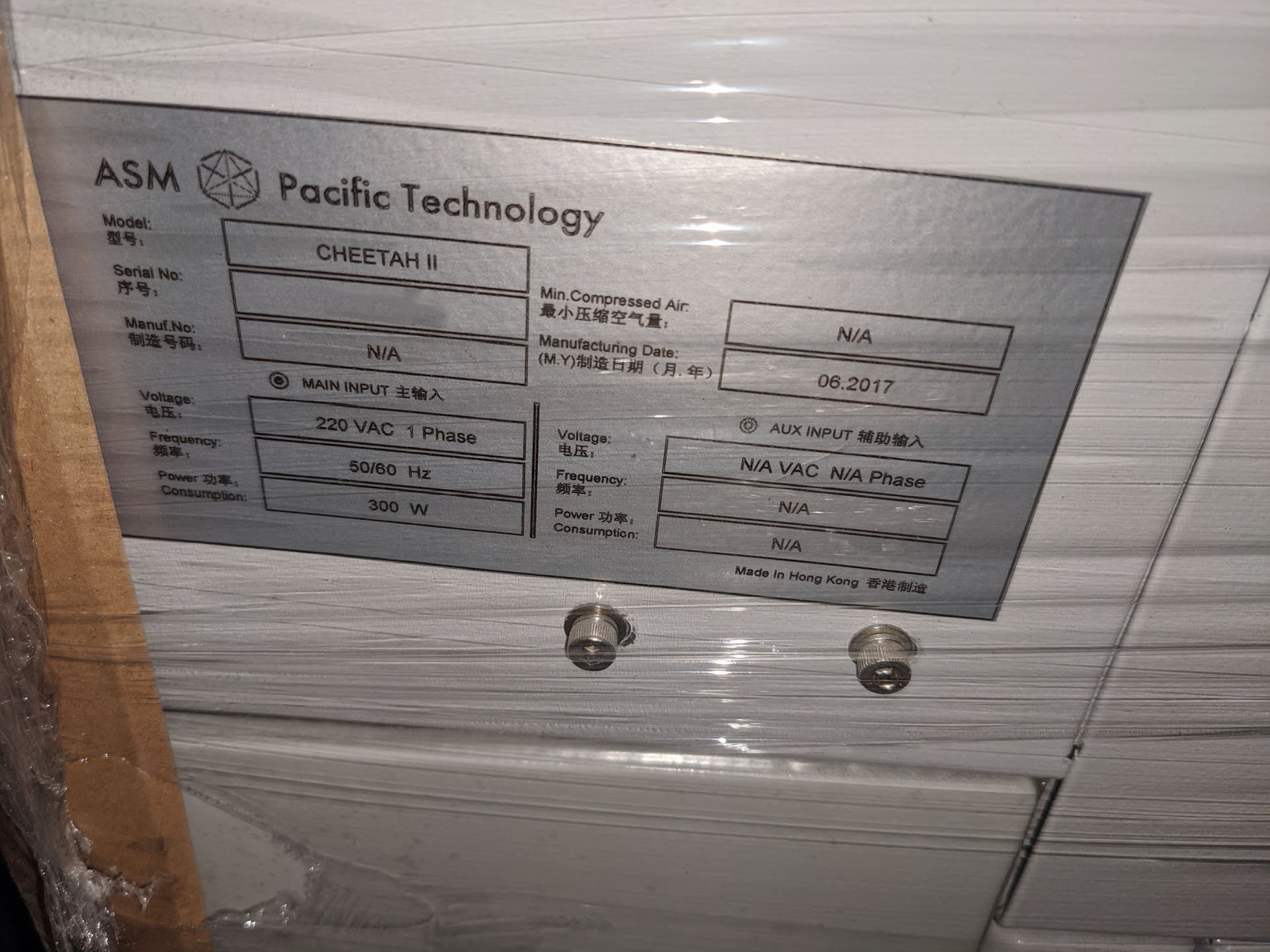

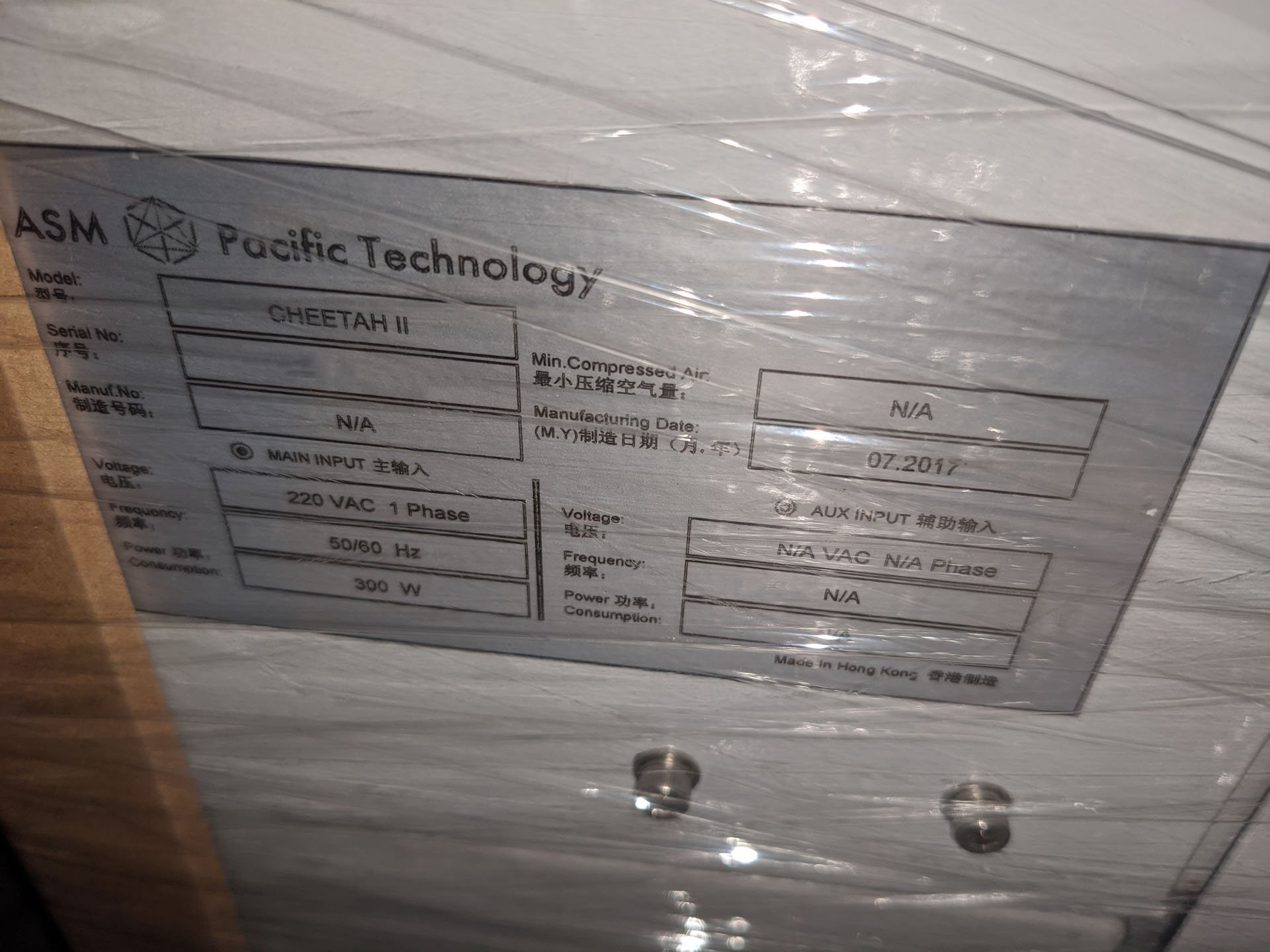

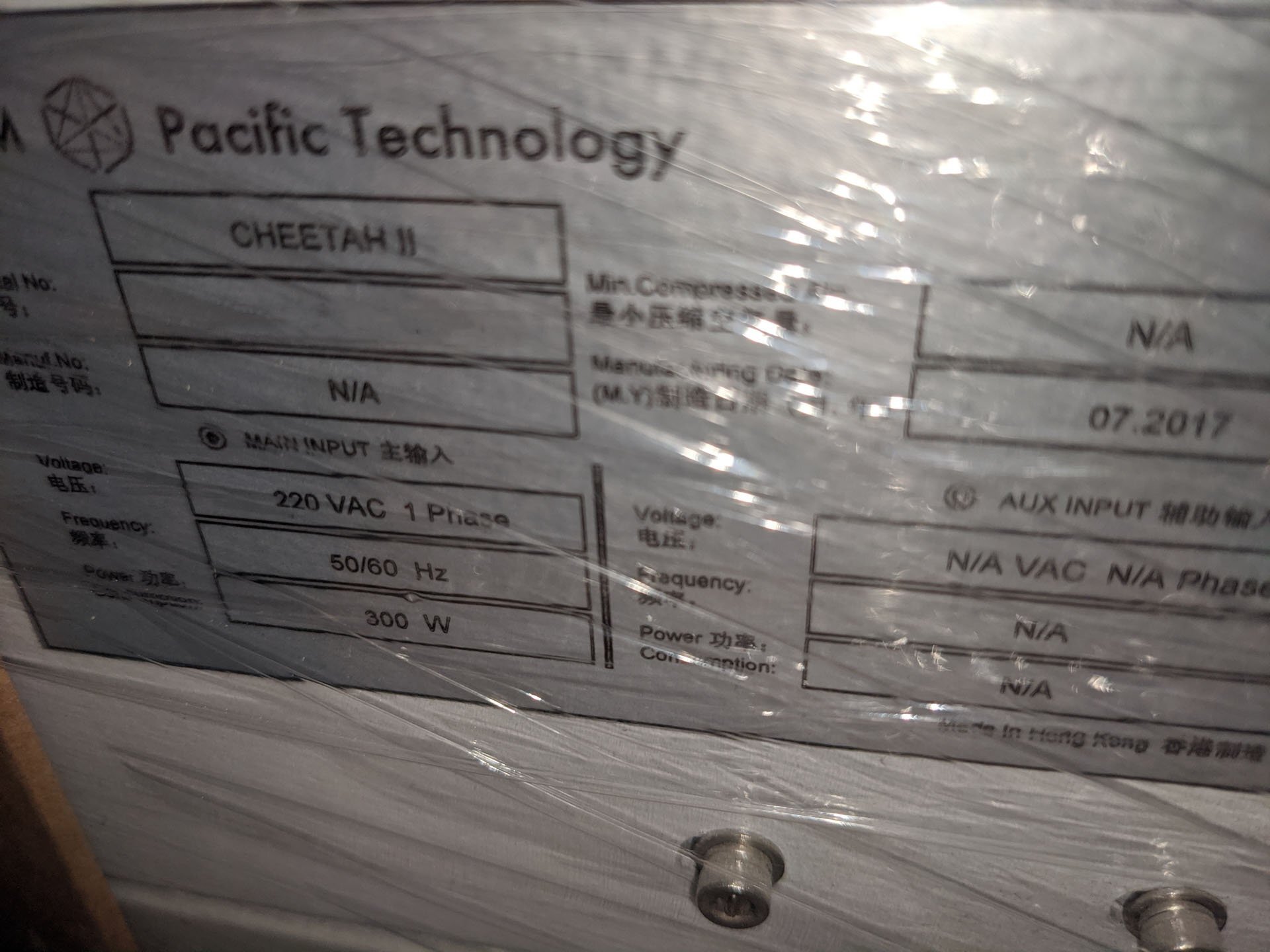

Used ASM Cheetah II #9364749 for sale

URL successfully copied!

Tap to zoom

ASM Cheetah II is a semi-automated high-precision die bonder that is used for day-to-day precision placement of small components for making semiconductor-related assemblies. The bonder is able to place a wide variety of component sizes, from 0603 to 55 millimeters, as well as all substrates (e.g. plastic lead frame, ceramic and glass carriers, ceramic substrates, and tape automated bonding) with high precision, accuracy, and reliability. Cheetah II enables precise fine-pitch placement of components which makes it suitable for bonding operations in both high-end and low-cost applications, especially for producing high-density multi-chip packages. The environmental control system is designed for constant temperature and eliminates temperature issues such as thermal drift. This ensures a precise placement, while the high resolution image capture camera ensures that the components are accurately located and placed on the substrate. ASM Cheetah II utilizes three types of die attach technology: thermosonic gold ball bonding, thermosonic copper wedge bonding, and ultrasonic wire bonding. The thermosonic gold ball bonding and thermosonic copper wedge bonding use high-frequency bursts of energy to attach wire bonding materials to the substrate, making them suitable for larger and heavier components; while ultrasonic wire bonding uses an abrupt vibration to attach small components to the substrate. The bonder also has a variety of additional features such as integrated programs for package forming, adhesive dispense, cutting, and marking. All of these features make Cheetah II suitable for high-volume production of automated assemblies. ASM Cheetah II has the ability to store up to 128 component sets, making it perfect for prototyping and small-volume production runs. Its ergonomic workstation provides a comfortable and ergonomic design which reduces user fatigue. Cheetah II can be controlled from either its integrated SPC (Statistical Process Control) system or from an external host computer, providing flexibility and seamless integration with production environments. The highly integrated software package is designed to monitor the bonder's performance and allow for adjustment of parameters such as temperature, power and speed. The software also provides maintenance and regular system performance checks in order to make sure that the bonder is operating at peak performance. All of these features make ASM Cheetah II a reliable and versatile die bonder that can be used in a variety of applications.

There are no reviews yet