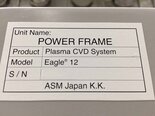

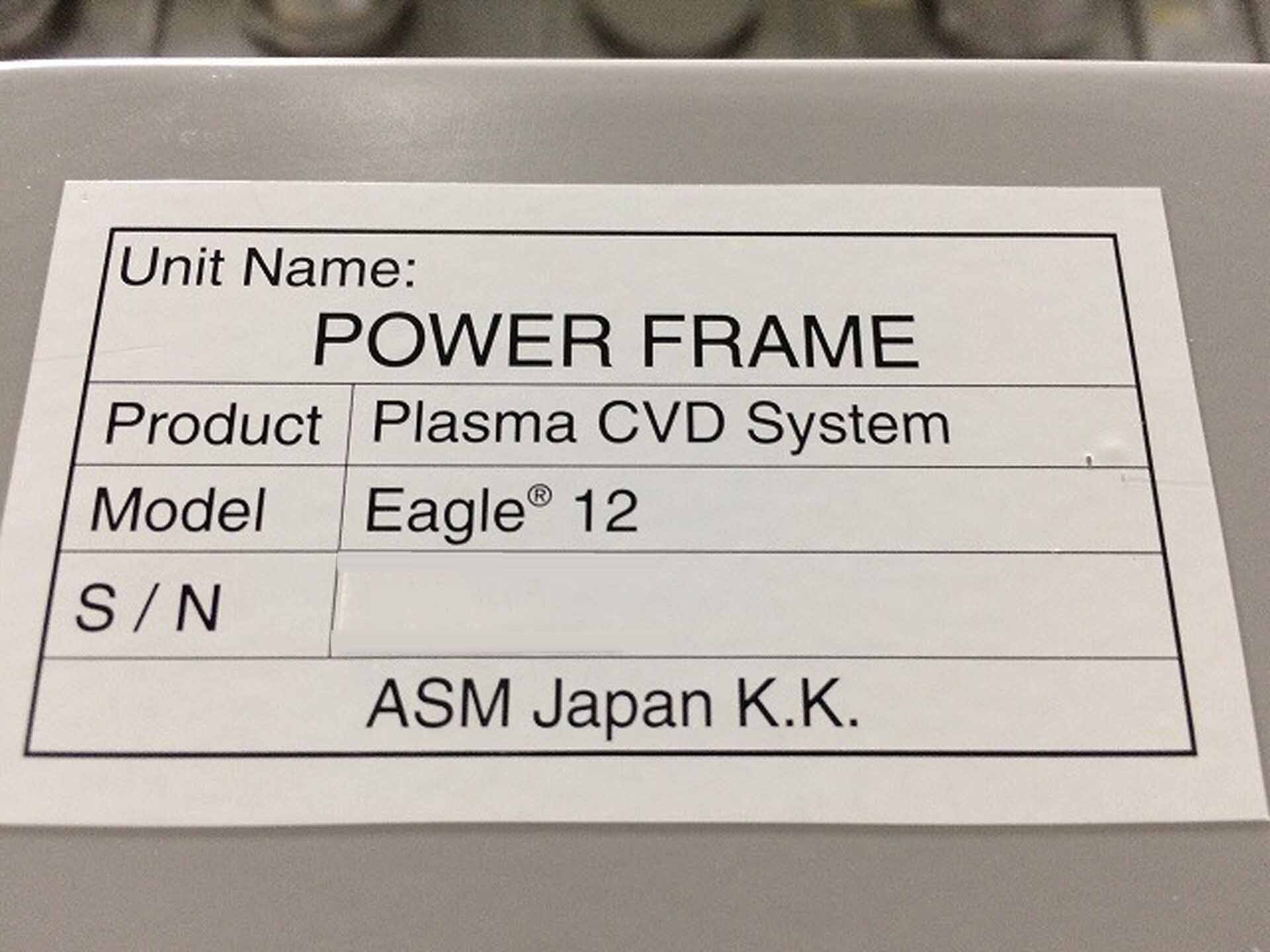

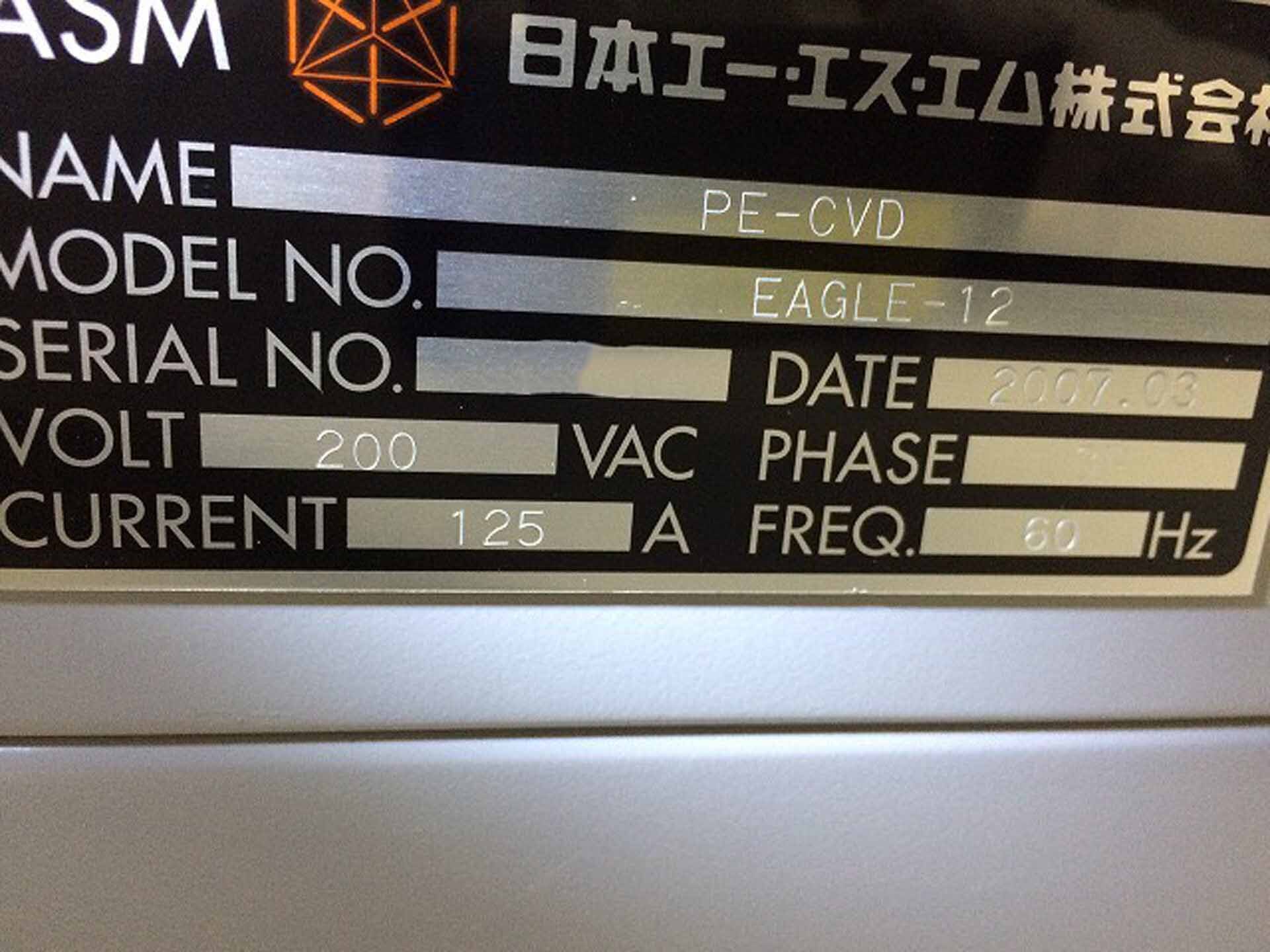

Used ASM EAGLE 12 #9386735 for sale

URL successfully copied!

Tap to zoom

ASM EAGLE 12 is a wire bonding equipment that is designed and manufactured by ASM Assembly Systems. The system is both accurate and reliable and is used in production of a wide range of semiconductor and microelectronic components. The unit runs over a full range of manufacture and test operations and is suitable for Automatic and Semi-Automatic applications. ASM EAGLE-12 consists of a Bond Head, Controllers, and Machine Logic controllers. The Bond Head control tool enables an operator to program the machine with the desired parameters to ensure that the correct wire is used and that the desired shape of the wire bonds are correctly formed and secured. The asset also provides the operator with feedback in terms of net speed, wire temperature, and other factors to ensure that the best bonding performance is obtained. The Controllers include a number of components, including the PLC, that handle the operational tasks of the model and provide a smooth, sleek operation during wire bonding. The Equipment Logic controllers manage the operation of the system by providing data that is used for controlling the unit settings. The machine is designed to work with a range of wires, including a variety of ribbon and discrete wire connections. This provides flexibility and flexibility to accommodate the needs of the end user. The tool can also accommodate various accessories such as wire jumpers, magnetics, and tools to improve the wire bonding process. The asset allows the operator to program the machine to move the wire within a certain area or at a certain speed, and this allows for a higher level of accuracy and repeatability in the wire bonding process. The programmable functions also reduce the possibility of human errors as an operator is not required to manually adjust the settings for optimal results. In conclusion, EAGLE 12 is an advanced wire bonding model that offers a great level of flexibility, accuracy, and repeatability during the wire bond process. The equipment is suitable for both automatic and semi-automatic applications and provides an operator with a great level of control over the entire process.

There are no reviews yet