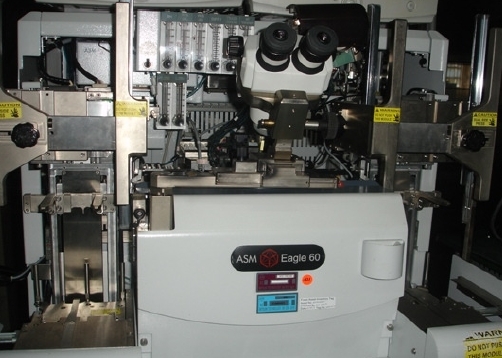

Used ASM Eagle 60 #119315 for sale

URL successfully copied!

Tap to zoom

ID: 119315

Vintage: 2004

Automatic wire bonder

Copper wire kit Included

2004 vintage.

ASM Eagle 60 is an advanced semiconductor bonder used for creating semiconductor devices. It is a versatile machine capable of performing a variety of applications in the semiconductor industry. It has an advanced control equipment enabling the user to calibrate the parameters for exact control over the assembly process. Eagle 60 is an integrated bonder platform featuring an automated 400kHz ultrasonic wire bonder. It can be used to make ultra-fine high-performance flat and round wire bonding, as well as ribbon and wedge bonding. The machine features an intuitive user interface that can connect to both standard and custom workstations. This interface enables simple operation by any user and allows custom programs to be loaded and monitored. The machine is equipped with an advanced vision system which can be used to recognize various bonding parameters and identify wire end shapes. This feature prevents defective bonds, allowing for higher yields and reliability in the assembly process. It also has a feature called Auto-Start, which can detect malfunctions such as wire breakages or poor adhesion of the bond and stop the process. ASM Eagle 60's speed and accuracy make it ideal for applications such as advanced Flip Chip, RFID, MEMs, High-Voltage, 3D memory chip, passive and active components. Additionally, it is capable of producing high-precision dieattach bonds, providing the facility to bond QFNs, DIPs, and stacked dieunits. Eagle 60 bonder is also equipped with a sophisticated servo drive unit, providing a smooth and precise bonding process. It uses advanced Arc welding, which produces quality results with high-speed accuracy. The machine also has a monitoring machine which can trace the temperature of the bonder during the bonding process to ensure optimal performance. Overall, ASM Eagle 60 is an advanced bonder designed to meet the needs of companies in the semiconductor industry. It offers reliability, high speed, and accuracy, making it a great choice for producing high-quality products. Its intuitive user interface and advanced vision tool allow for easy programming and control, resulting in fewer defects and higher yields in the assembly process.

There are no reviews yet