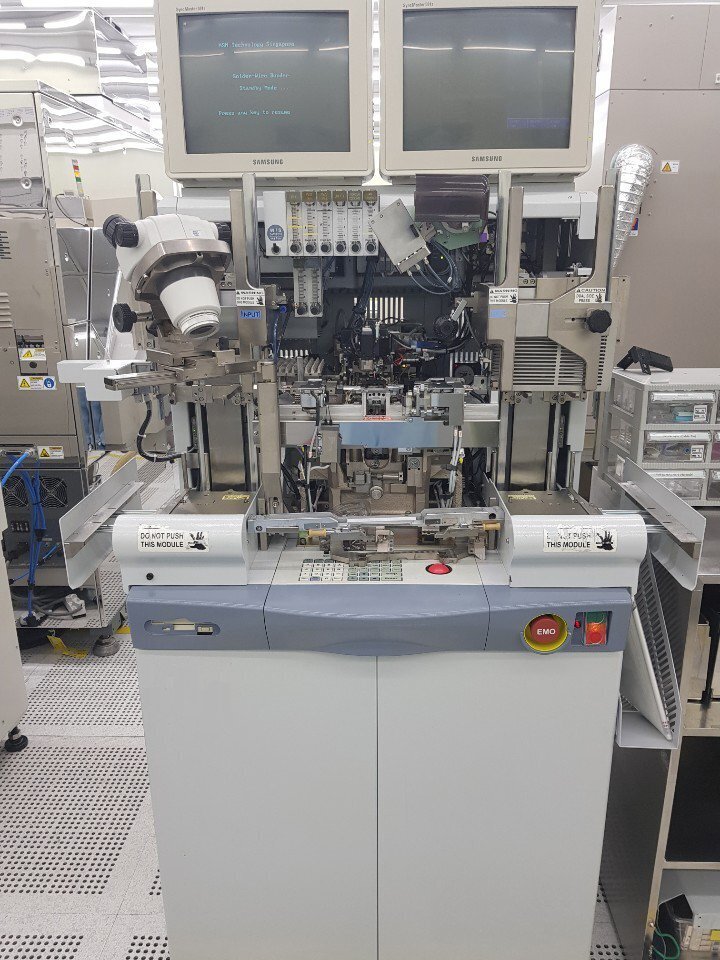

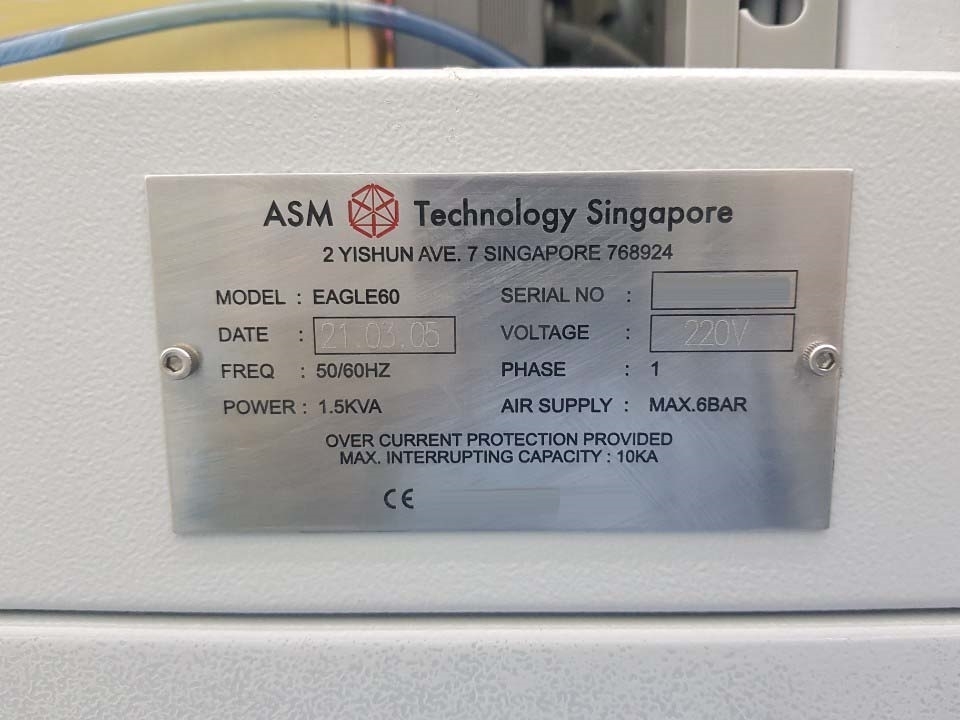

Used ASM Eagle 60 #9208411 for sale

URL successfully copied!

Tap to zoom

ID: 9208411

Vintage: 2005

Wire bonder

Ambient temperature: 5°C - 40°C

Humidity: <80%

Bonding method: THERMOSONIC (TS)

BQM Mode:

Constant current

Voltage

Power and normal

Loop type: Normal, low, square, penta and J

X, Y Resolution: 0.2 µm

Z Resolution (Capillary travelling motion): 0.4 µm

Fine pitch capability: 35 µm Pitch at 0.6 mil wire

Bonding wires: Up to 3000

Program storage: 1000 Programs on hard disk

Multimode transducer system: Control and vibration modes

Vision system:

Pattern recognition time: 60 ms / Point

Pattern recognition accuracy: ±0.37 µm

Lead locator detection: 12 ms / Lead (3 Leads / Frame)

Lead locator accuracy: ±2.4 urn

Maximum die level different: 400-500 µm

Material handling system:

Indexing speed: 200-250 ms at 0.5" Pitch

Indexer resolution: 1 µm

Lead frame position accuracy: ±2 Mil

Lead frame:

Width:

24-73 mm at Bonding area in Y: 65 mm

24-90 mm at Bonding area in Y: 48 mm

Maximum length: 280 mm

T: 0.075-0.8 mm

Applicable magazine:

Maximum width: 98 mm

Length: 140-280 mm

Maximum height: 180 mm

Magazine pitch: 2.4-10 mm (0.09" - 0.39")

Device changeover: <4 minutes

Package changeover: <5 minutes

(3) Buffer magazines: 435 mm (maximum)

Power supply:

Compressed air: 152 LPM Maximum at 3-6 bar

Voltage: 110 VAC

Voltage tolerance: +10%

Frequency: 50 Hz

Frequency tolerance: ±1%

Single phase

Power consumption: 1500 W

2005 vintage.

ASM Eagle 60 is a high-precision bonder made for assembling small surface mount devices. It is designed for assembling components with a nominal size of 0201 up to special sizes of 0.5 mm pitch IC and across various substrates and package types. Eagle 60 is a powerful bonder that offers a wide range of capabilities to meet the needs of the most demanding applications. ASM Eagle 60 utilizes an ergonomically designed operator interface to ensure the best ergonomics for the user. A large, flat LCD display with full-color touch-sensitive graphics deliver easy and intuitive control of the machine. Multi-level menus provide quick access to all machine functions. This bonder can also perform a wide variety of programmed user functions without manual intervention, enabling the operator to remain focused and productive. Eagle 60 is equipped with four bond heads which can be configured to function in spot, drag, wedge wedging and gold ball bonding modes. These four heads are driven by three separately controlled high-precision servo motors. The integrated camera equipment is combined with sophisticated software algorithms to accurately align components to their designated positions. ASM Eagle 60 also includes a state-of-the-art vision system for improved accuracy and repeatability. Eagle 60 is designed to work with a wide range of materials including copper, multiple varieties of aluminum and stainless steel. ASM Eagle 60 can also accommodate a wide range of substrates such as FR4, Kapton, epoxy, and ceramic. Its sophisticated on-board control unit ensures finest bonding process control as it constantly monitors bonding conditions to ensure repeatability and accuracy. A totally enclosed work space with forced air cooling and positive pressure evacuate released vapors for optimal working environment conditions. Eagle 60 is fitted with several fail-safe features and safeguards. In the event of an emergency, an integrated safety machine will stop the process to prevent injury. ASM Eagle 60 also features a variety of alarms and alerts, including audible and visual warning signals to alert the operator of specific issues or errors. These features allow for greater user confidence and increased uptime. Eagle 60 provides a powerful, easy-to-use, and reliable solution for complex and precision bonding applications. Its advanced bonding capabilities, user-friendly ergonomic design, and safety features make it a reliable and efficient choice for even the most demanding requirements.

There are no reviews yet