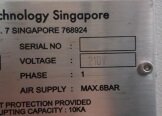

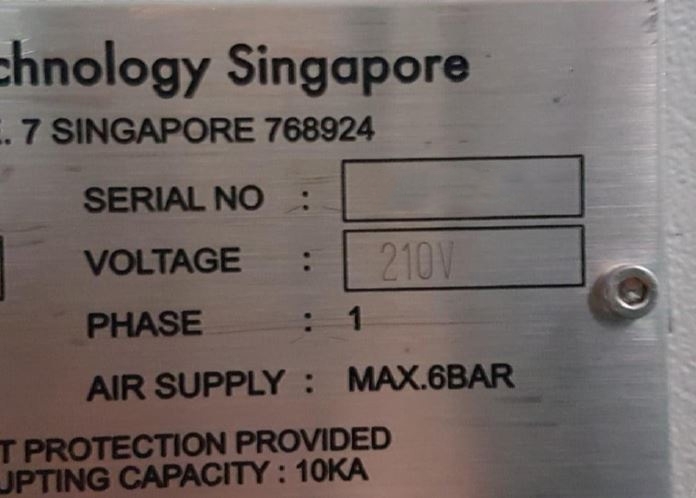

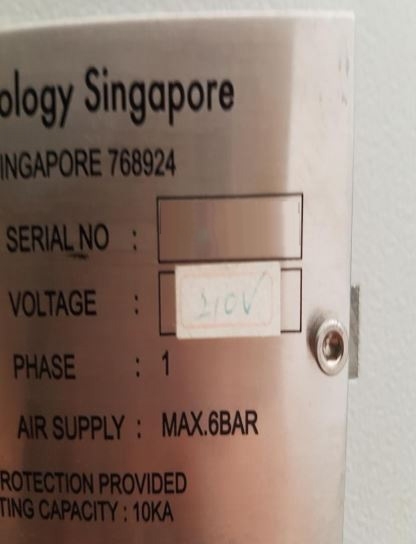

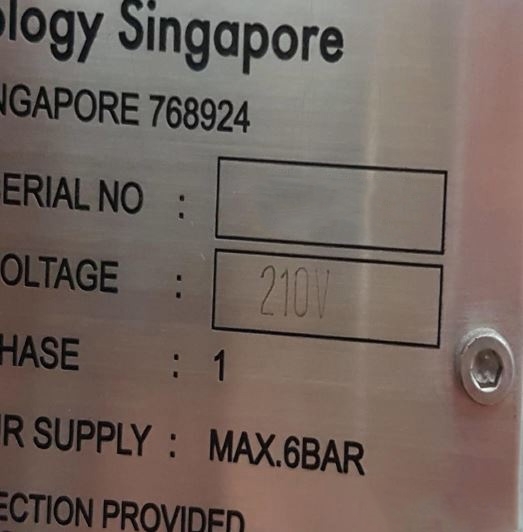

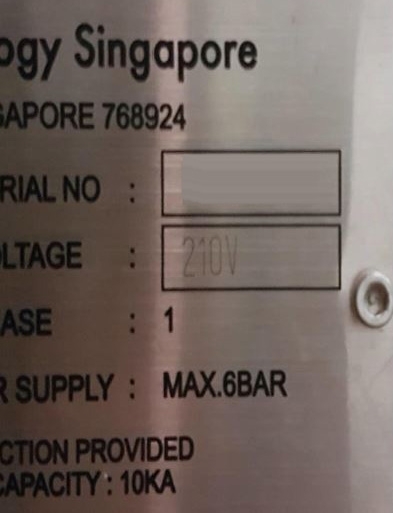

Used ASM Eagle 60 #9246851 for sale

URL successfully copied!

Tap to zoom

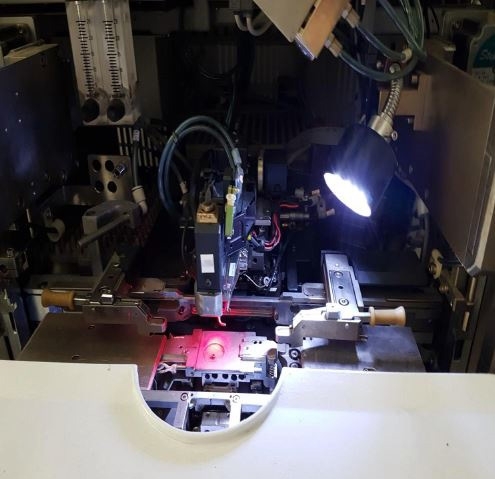

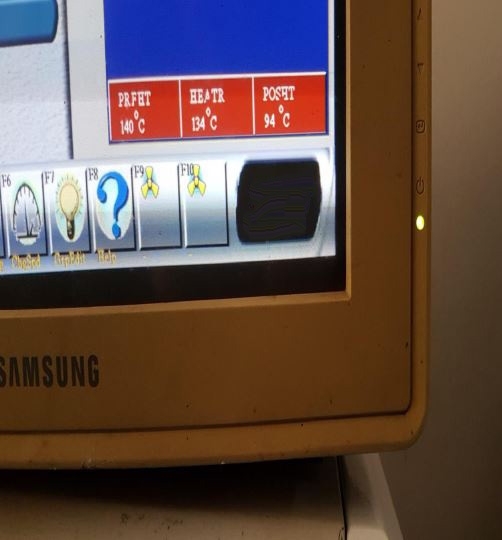

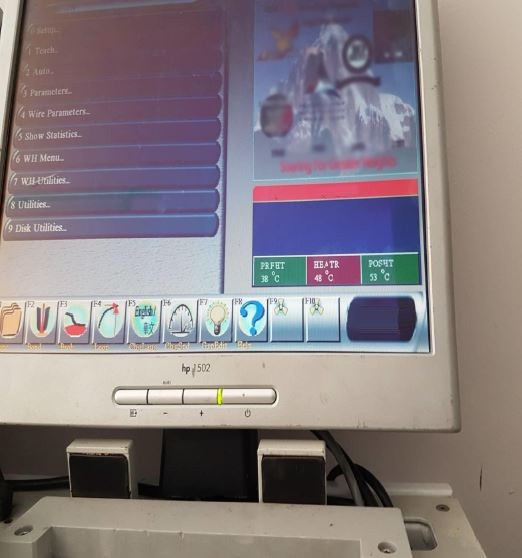

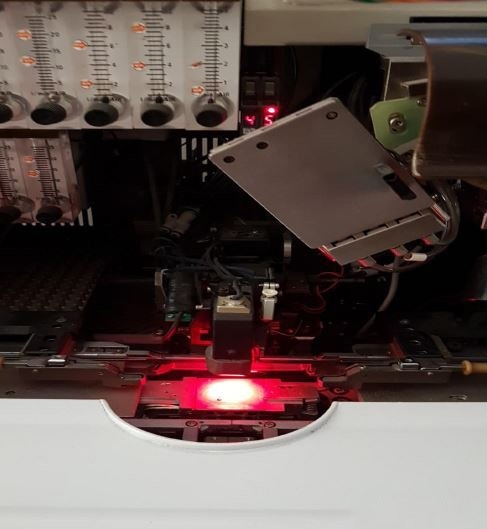

ASM Eagle 60 is an automated bonding system that streamlines and simplifies the process of creating electrical connections in a variety of assembly applications. It is suitable for any industry where high-volume, high-reliability bonding is required, such as aerospace, automotive, medical device, and semiconductor industries. Eagle 60 consists of an industrial robot manipulator, an automatic material feeder, and a mechanical bonding head. The robot manipulator moves the mechanical bonding head around the device to be assembled, allowing it to be positioned in areas that are difficult to access manually. The automatic material feeder is equipped with a high-speed insulation displacement contact (IDC) applicator, which moves across the device to be assembled, adding great accuracy and precision to the process. ASM Eagle 60 has several features which set it apart from other bonding systems. It offers a range of standard and custom-made bonding solutions for a wide range of applications, such as wire wrapping, IDC-IDC connect, cone-form crimping, wire-to-wire bonding, resistor/diode attatchment and sampling. Eagle 60 also features an advanced control system, which allows for simple integration with other automation systems and provides high-level accuracy for optimal results. An interesting feature of ASM Eagle 60 is its intuitive user interface, which is designed to make programming easy. The entire bonding process is programmed via a simple graphical user interface, which allows the operator to visualize the process, making the programming process faster and easier. Eagle 60 is also equipped with the latest safety protocols, such as a password-protected system to prevent unauthorised access and double-safety door locks to ensure proper isolation of power and operation in potentially hazardous environments. ASM Eagle 60 is ideal for high-volume, high-reliability bonding jobs. Its intuitive UI and advanced features make it perfect for any industry where precision and accuracy are key, and its range of standard and custom-made solutions make it an efficient and reliable choice in a wide range of assembly applications.

There are no reviews yet