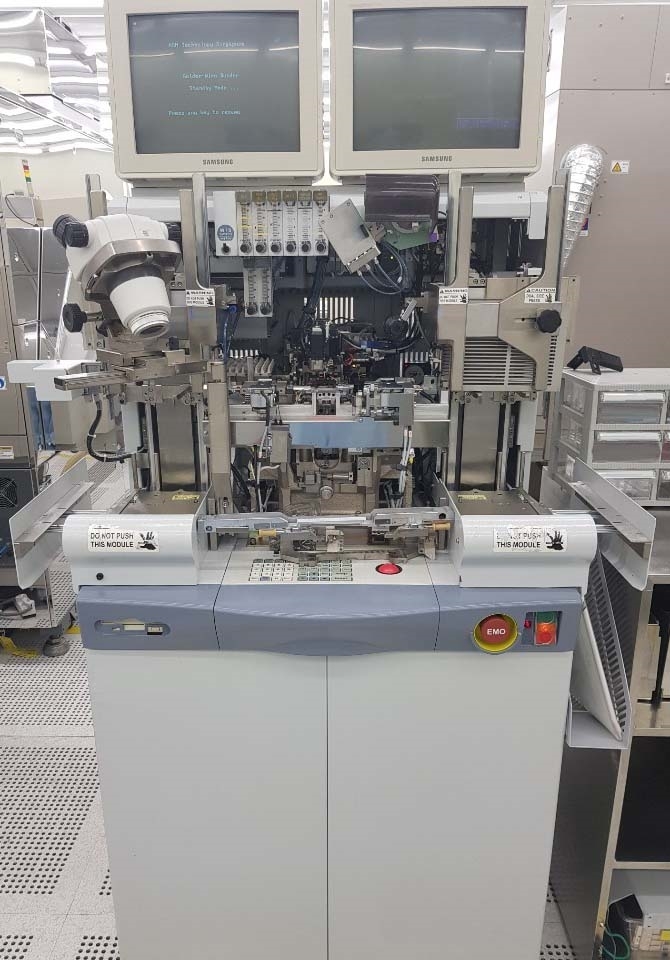

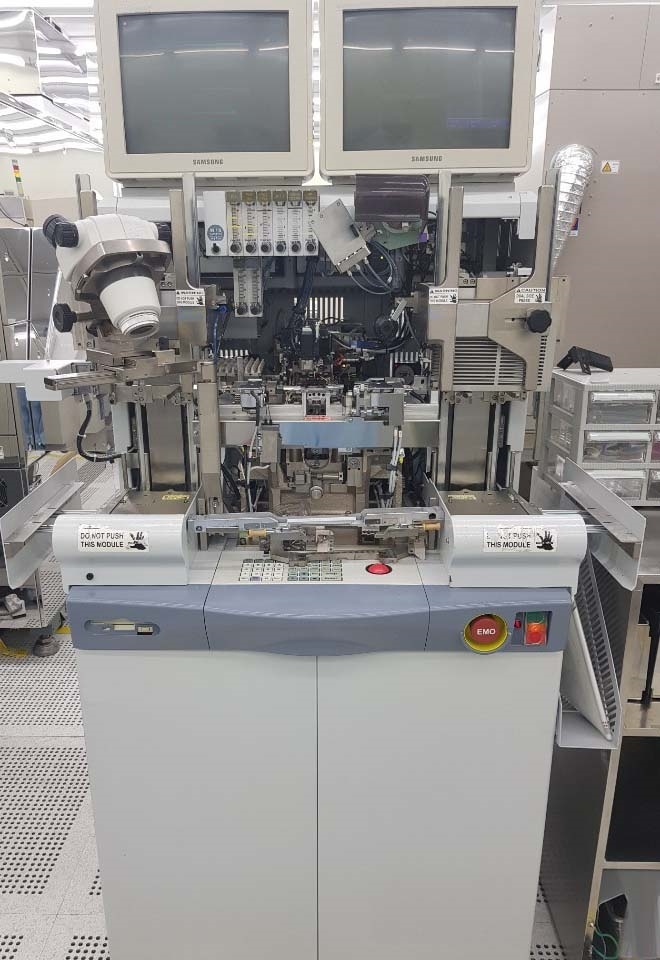

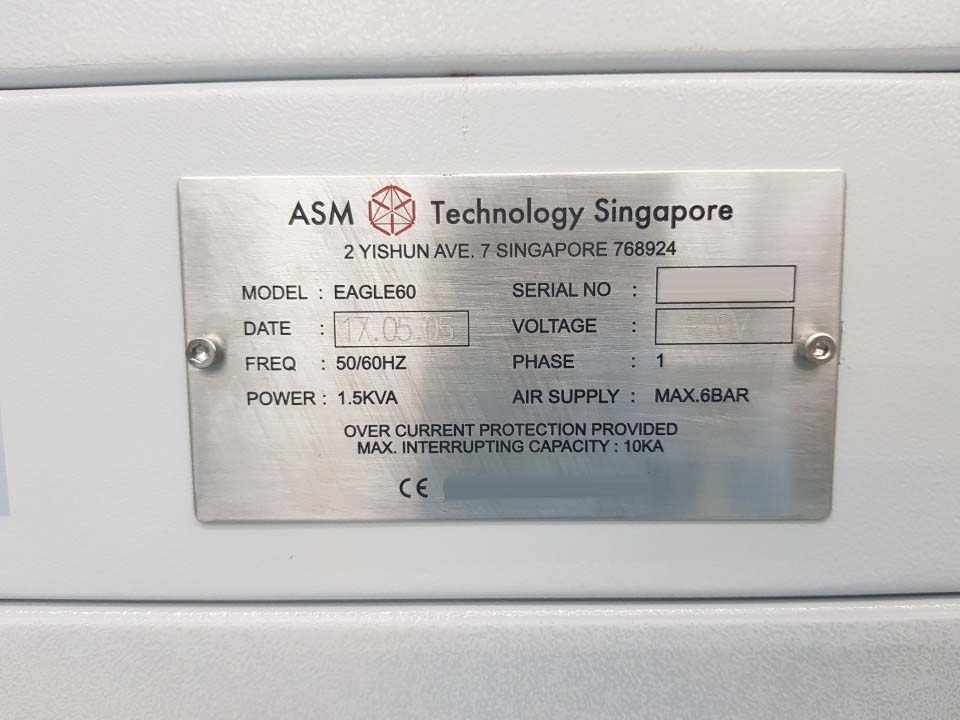

Used ASM Eagle 60 #9288232 for sale

URL successfully copied!

Tap to zoom

ID: 9288232

Vintage: 2005

Wire bonder

Ambient temperature: 5°C - 40°C

Humidity: <80%

Bonding method: THERMOSONIC (TS)

BQM Mode:

Constant current

Voltage

Power and normal

Loop type: Normal, low, square, penta and J

X, Y Resolution: 0.2 µm

Z Resolution (Capillary travelling motion): 0.4 µm

Fine pitch capability: 35 µm Pitch at 0.6 mil wire

Bonding wires: Up to 3000

Program storage: 1000 Programs on hard disk

Multimode transducer system: Control and vibration modes

Vision system:

Pattern recognition time: 60 ms / Point

Pattern recognition accuracy: ±0.37 µm

Lead locator detection: 12 ms / Lead (3 Leads / Frame)

Lead locator accuracy: ±2.4 urn

Maximum die level different: 400-500 µm

Material handling system:

Indexing speed: 200-250 ms at 0.5" Pitch

Indexer resolution: 1 µm

Lead frame position accuracy: ±2 Mil

Lead frame:

Width:

24-73 mm at Bonding area in Y: 65 mm

24-90 mm at Bonding area in Y: 48 mm

Maximum length: 280 mm

T: 0.075-0.8 mm

Applicable magazine:

Maximum width: 98 mm

Length: 140-280 mm

Maximum height: 180 mm

Magazine pitch: 2.4-10 mm (0.09" - 0.39")

Device changeover: <4 minutes

Package changeover: <5 minutes

(3) Buffer magazines: 435 mm (maximum)

Power supply:

Compressed air: 152 LPM Maximum at 3-6 bar

Voltage: 110 VAC

Voltage tolerance: +10%

Frequency: 50 Hz

Frequency tolerance: ±1%

Single phase

Power consumption: 1500 W

2005 vintage.

ASM Eagle 60 is a semi-automatic, precision bonding equipment specifically designed for hi-density printed circuit board (PCB) production and advanced surface-mount applications. The system features a high-speed robotic arm, precision XY stages, a dual axis high-accuracy PID temperature controller, and an automation-ready control unit. Its heavy-duty design ensures reliable and consistent operation, while its automated features minimize operator intervention. Eagle 60 uses a high-precision linear motor along with high-torque encoders at both ends to ensure precise alignment between pins and pads on the board. Additionally, a high-accuracy camera-based vision machine ensures correct vision alignment for both top and bottom sides of the board. Its standard automated dispensing and printing unit enables precise pre-application of bond material for better repeatability and control of the procedure. ASM Eagle 60 features an ergonomic design that minimizes operator fatigue, while also supporting high throughput of multiple products. Its adjustable process keys and command sequences allow the operator to fine-tune parameters for optimal results. Its automated features further minimize operator intervention, thanks to its fast, accurate, and repeatable PCB placement. Eagle 60 bonding tool ensures reliable throughput and quality through monitored variables such as temperature, bonding force, and time. It can provide precise evaluation and support of bonding parameters and traceability of output via internal data logging. Its advanced temperature controller allows fine-tuning of temperature parameters with adjustability to 0.2°C, ensuring superior accuracy of parameters for optimal results. Its flexibility and scalability allow ASM Eagle 60 to be customized for different applications. Optional components such as an Indexers, Pyrozoners, and IntelliJet printing systems enable faster and more efficient production cycles. Additionally, a wide range of accessories can be integrated with the asset, including vacuum pumps, cooling systems, bonding wire, and large-scale product cleaning. Eagle 60 is the perfect choice for high speed, high-precision PCB production and advanced surface-mount applications. Its robust design, loading capability, automation-ready control model, and advanced vision equipment make it an ideal solution for demanding production requirements.

There are no reviews yet