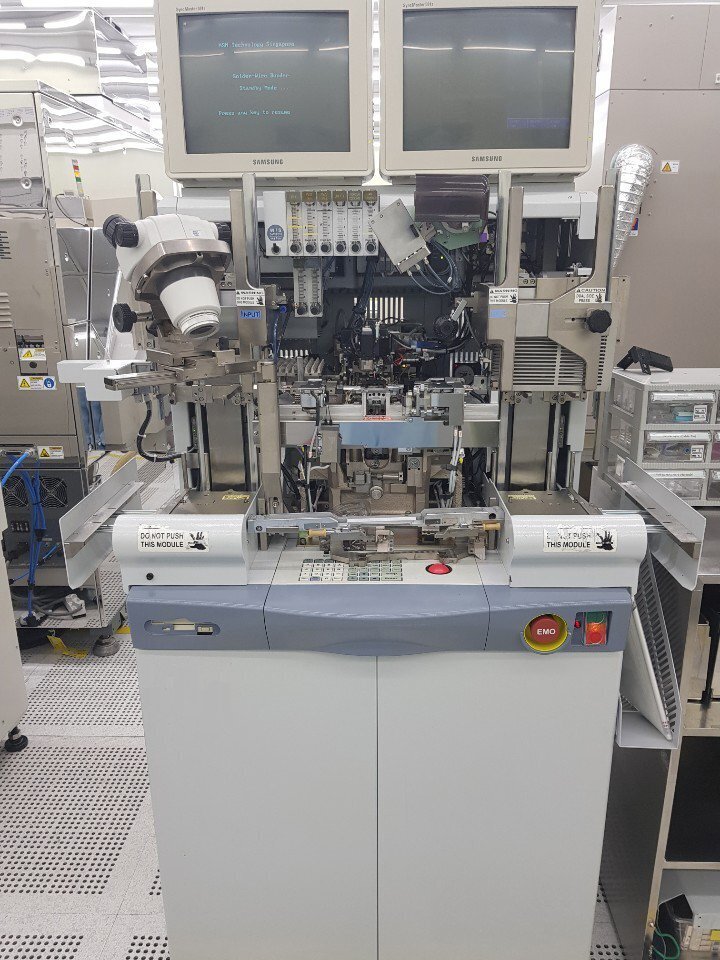

Used ASM Eagle 60 #9290131 for sale

URL successfully copied!

Tap to zoom

ID: 9290131

Vintage: 2004

Wire bonder

Ambient temperature: 5°C - 40°C

Humidity: <80%

Bonding method: THERMOSONIC (TS)

BQM Mode:

Constant current

Voltage

Power and normal

Loop type: Normal, low, square, penta and J

X, Y Resolution: 0.2 µm

Z Resolution (Capillary travelling motion): 0.4 µm

Fine pitch capability: 35 µm Pitch at 0.6 mil wire

Bonding wires: Up to 3000

Program storage: 1000 Programs on hard disk

Multimode transducer system: Control and vibration modes

Vision system:

Pattern recognition time: 60 ms / Point

Pattern recognition accuracy: ±0.37 µm

Lead locator detection: 12 ms / Lead (3 Leads / Frame)

Lead locator accuracy: ±2.4 urn

Maximum die level different: 400-500 µm

Material handling system:

Indexing speed: 200-250 ms at 0.5" Pitch

Indexer resolution: 1 µm

Lead frame position accuracy: ±2 Mil

Lead frame:

Width:

24-73 mm at Bonding area in Y: 65 mm

24-90 mm at Bonding area in Y: 48 mm

Maximum length: 280 mm

T: 0.075-0.8 mm

Applicable magazine:

Maximum width: 98 mm

Length: 140-280 mm

Maximum height: 180 mm

Magazine pitch: 2.4-10 mm (0.09" - 0.39")

Device changeover: <4 minutes

Package changeover: <5 minutes

(3) Buffer magazines: 435 mm (maximum)

Power supply:

Compressed air: 152 LPM Maximum at 3-6 bar

Voltage: 110 VAC

Voltage tolerance: +10%

Frequency: 50 Hz

Frequency tolerance: ±1%

Single phase

Power consumption: 1500 W

2004 vintage.

ASM Eagle 60 is a reliable fully automatic wire bonding machine that offers superior flexibility and is designed to ensure fast and reliable wire bonds. It is ideal for a wide range of industries including electronics, automotive, medical, Aerospace, optoelectronics, military, and others. Eagle 60 uses an advanced ultrasonic welding tool that ensures high-quality soldered connections. Its AC servo motor technology makes it efficient and its touchscreen operator interface makes it easy to use. The system's onboard automation and optimization features make it possible to adjust wire bonding parameters for greater precision and speed. Additionally, ASM Eagle 60 is capable of bonding a range of wire sizes and materials - from copper and gold to aluminum, silver, and carbon. This versatility allows a wide range of applications from high- and medium-volume production lines. Eagle 60 is designed to handle large jobs quickly and efficiently, with an integrated component placement system that eliminates manual assembly and improves productivity. Its honed design also offers superior lamp, induction, and vision adjustment capabilities for faster inspections and fewer scrap components. ASM Eagle 60 offers a compact but diverse wire bonding range and high accuracy. Its 18-programmable-drive motion control system allows the operator to program different cycle settings and tension recommendations. Additionally, Eagle 60 supports a variety of bonding head shapes, heat stake tooling, and pliers. ASM Eagle 60 includes built-in diagnostic features that allow users to track, troubleshoot, and record data regarding wire bonding conditions. The onboard USB port is used for logging data recorded during the operation. The machine also has built-in safety features to protect the operator from pollutants, splashes, and other hazards. Eagle 60 is exceptionally user-friendly and is UL and CE certified for safety. Its robust design ensures high levels of reliability and accuracy while its user-friendly interface makes it easy to operate. As a result, ASM Eagle 60 is a reliable and cost-effective addition to the electronics production line.

There are no reviews yet