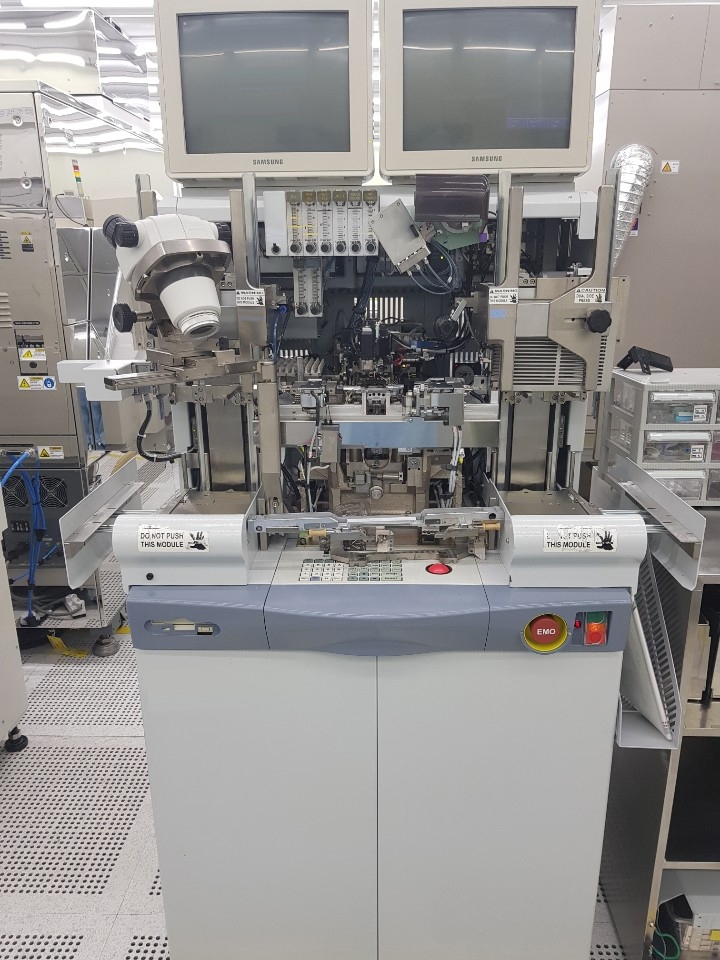

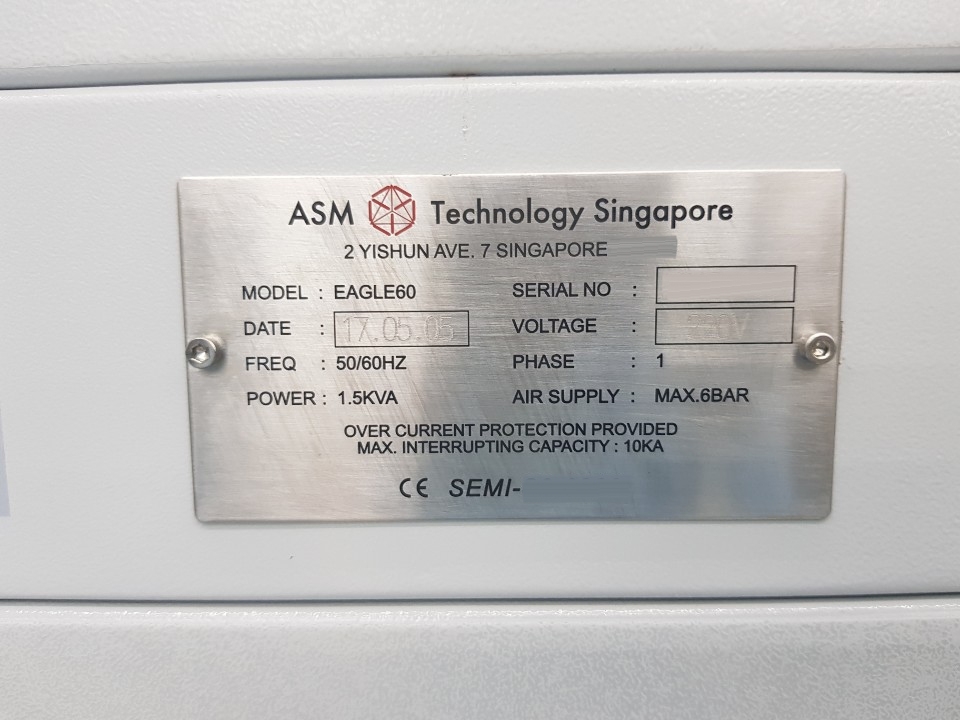

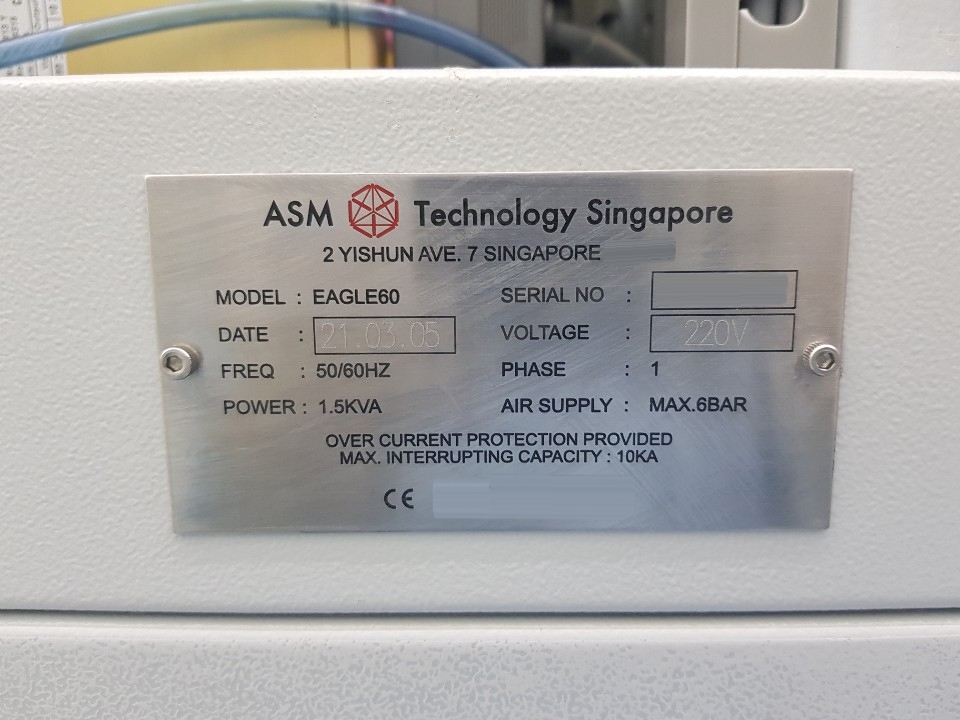

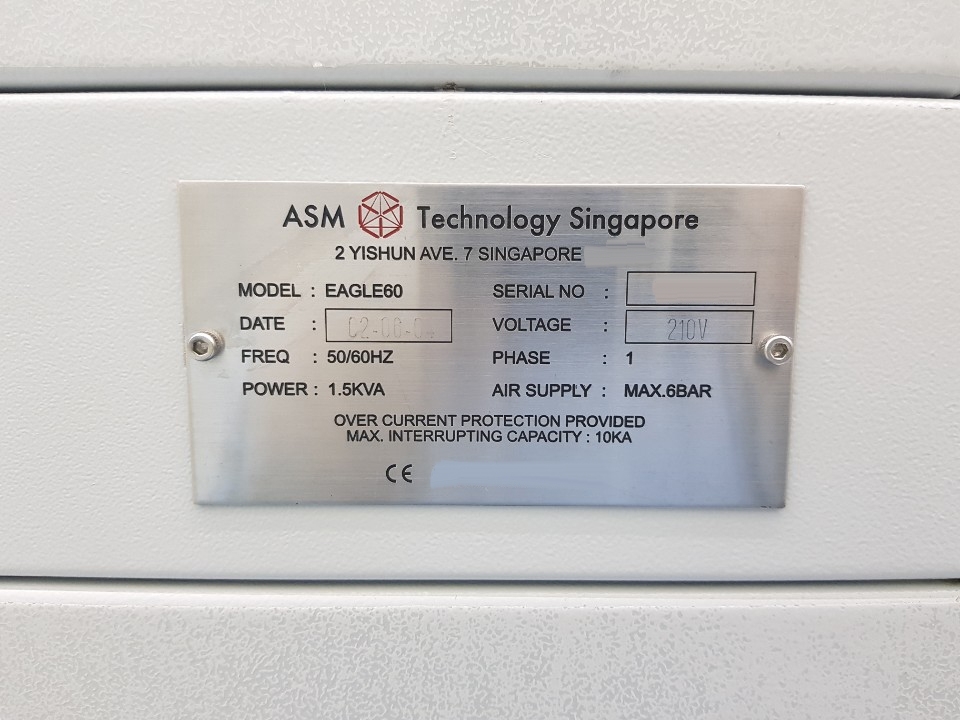

Used ASM Eagle 60 #9290132 for sale

URL successfully copied!

Tap to zoom

ID: 9290132

Vintage: 2005

Wire bonder

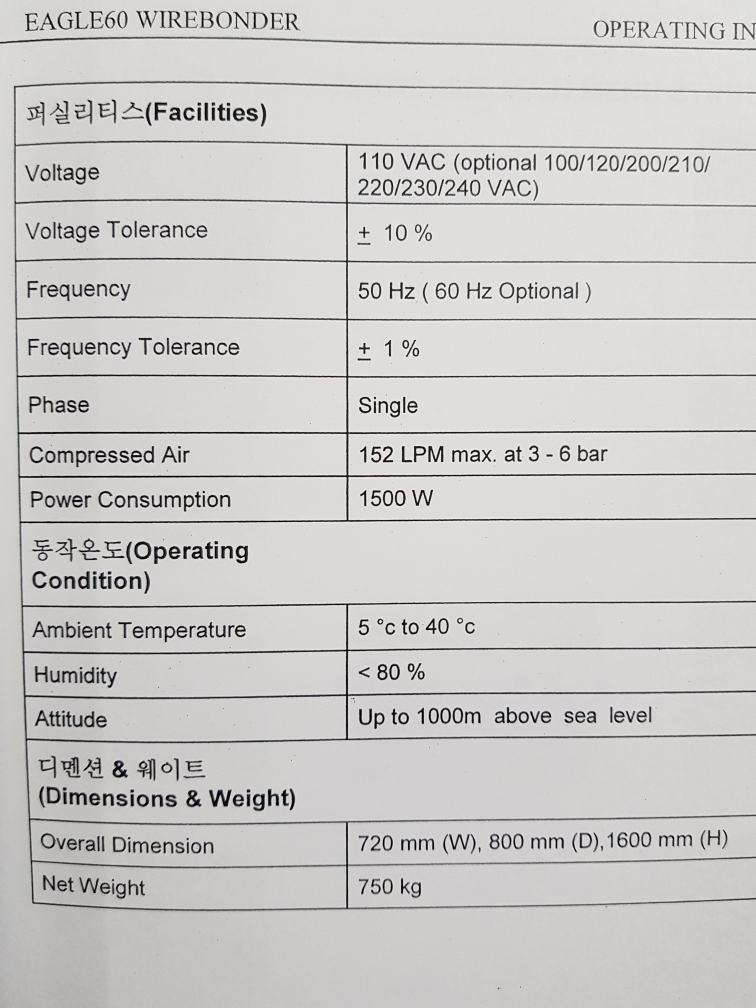

Ambient temperature: 5°C - 40°C

Humidity: <80%

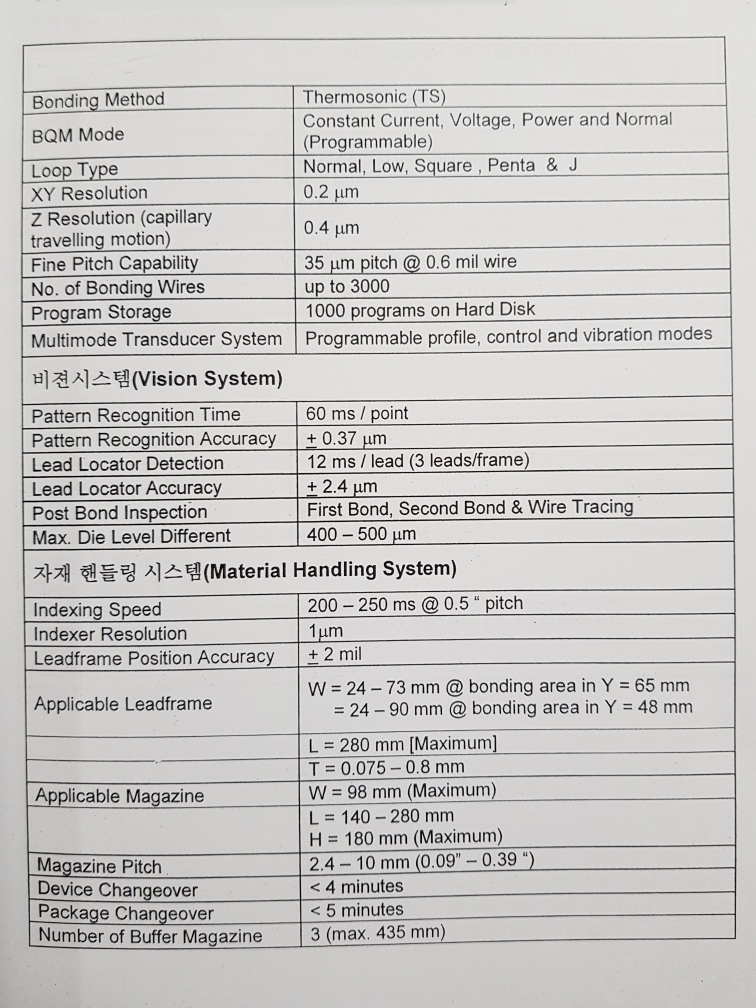

Bonding method: THERMOSONIC (TS)

BQM Mode:

Constant current

Voltage

Power and normal

Loop type: Normal, low, square, penta and J

X, Y Resolution: 0.2 µm

Z Resolution (Capillary travelling motion): 0.4 µm

Fine pitch capability: 35 µm Pitch at 0.6 mil wire

Bonding wires: Up to 3000

Program storage: 1000 Programs on hard disk

Multimode transducer system: Control and vibration modes

Vision system:

Pattern recognition time: 60 ms / Point

Pattern recognition accuracy: ±0.37 µm

Lead locator detection: 12 ms / Lead (3 Leads / Frame)

Lead locator accuracy: ±2.4 urn

Maximum die level different: 400-500 µm

Material handling system:

Indexing speed: 200-250 ms at 0.5" Pitch

Indexer resolution: 1 µm

Lead frame position accuracy: ±2 Mil

Lead frame:

Width:

24-73 mm at Bonding area in Y: 65 mm

24-90 mm at Bonding area in Y: 48 mm

Maximum length: 280 mm

T: 0.075-0.8 mm

Applicable magazine:

Maximum width: 98 mm

Length: 140-280 mm

Maximum height: 180 mm

Magazine pitch: 2.4-10 mm (0.09" - 0.39")

Device changeover: <4 minutes

Package changeover: <5 minutes

(3) Buffer magazines: 435 mm (maximum)

Power supply:

Compressed air: 152 LPM Maximum at 3-6 bar

Voltage: 110 VAC

Voltage tolerance: +10%

Frequency: 50 Hz

Frequency tolerance: ±1%

Single phase

Power consumption: 1500 W

2005 vintage.

ASM Eagle 60 is a precision bonder designed specifically for its ability to meet the high-accuracy requirements of industrial bonding. Eagle 60 can be used for a variety of surface-mount components, including wires, fine-pitch chips, and flip chips. The machine's small form factor and low cost make it an attractive option to a wide range of OEMs and contract manufacturers. The equipment's highly accurate thermocouples ensure precise temperature control; the system's dual-zone heater and split-control sensor also ensures good thermal-image repeatability. ASM Eagle 60 is equipped with a digital pressure controller, which allows for repeatable and accurate pressure control, as well as an advanced control unit which enables fast closed-loop control and reaction to dynamic load changes. Eagle 60 has two main process modules: the wire bondsmodule and theeutectic module. The wire bondsmodule uses piezoelectric needles to embed and form lead frames,which can be tailored for any shape or size of component. The eutectic module is capable of performing accurate placement, as well as precision application of eutectic material. In addition, ASM Eagle 60 has a high-stability process monitor which can detect process-related faults, as well as a fully programmable process controller, which allows for the programming of all process parameters. The machine also has user-friendly menu previews, which allow users to quickly and easily set up various machine configurations. In conclusion, Eagle 60 offers users an affordable, yet high-accuracy bonding solution. The machine's advanced thermal control capabilities, as well as its diverse bonding capabilities and user-friendly interface make it an attractive choice for many OEMs and contract manufacturers. With its small form factor, this machine is the perfect choice for production floor environments.

There are no reviews yet