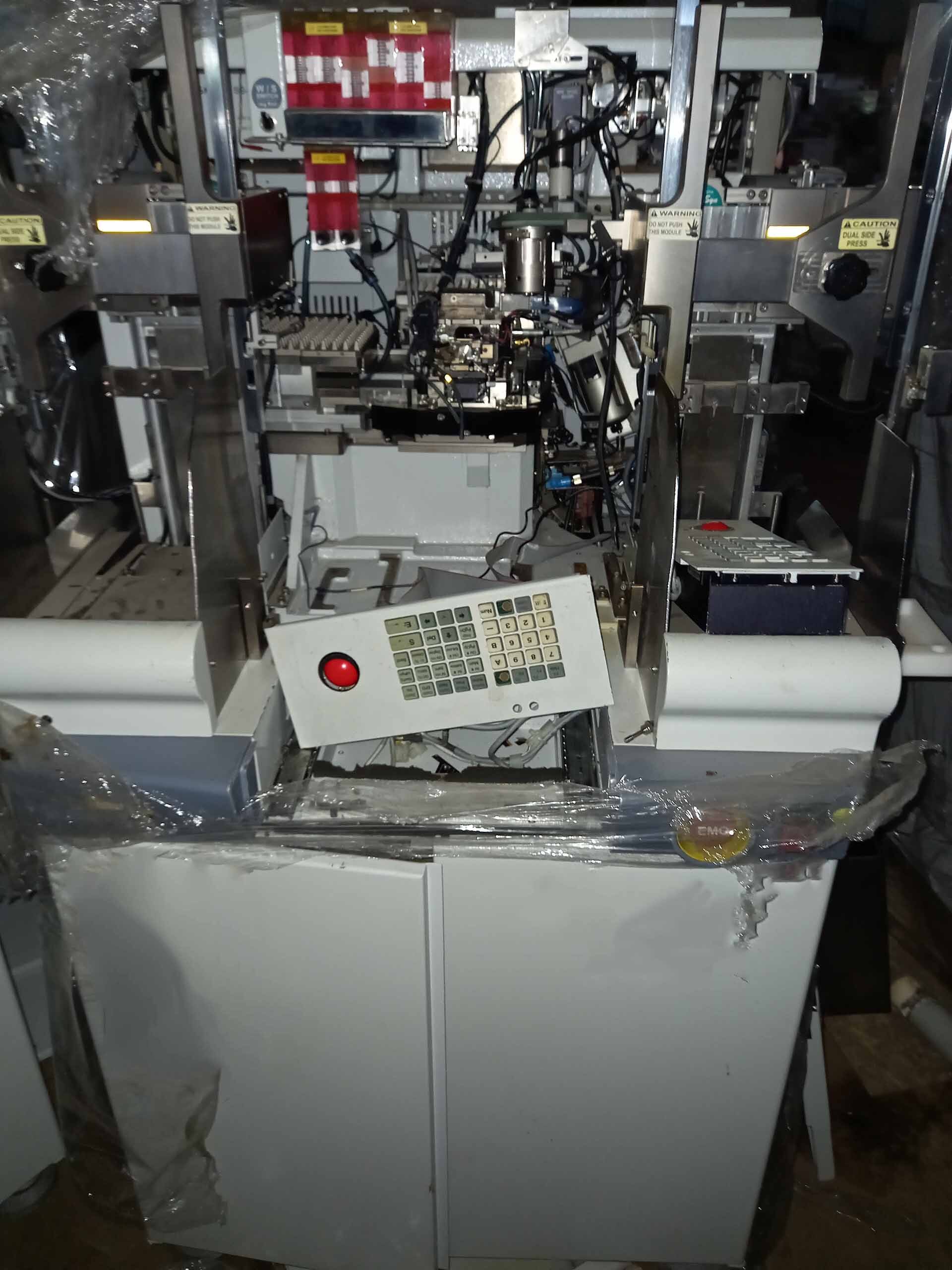

Used ASM Eagle 60 #9396315 for sale

URL successfully copied!

Tap to zoom

ASM Eagle 60 is an advanced Microsystems Mechanic (MSM) wire bonder designed to meet the demands of a wide range of production environments. This bonder uses superior temperature control, speed, accuracy, and repeatability to produce reliable connections between components and circuitry on printed circuit boards. Eagle 60 also offers advanced post-bonding features such as wire spooling, camera inspection, and semi-automatic functions. ASM Eagle 60 utilizes a multi-zone design that uses a controlled thermal anvil to bond insulated wire leads onto pins or pads on printed circuit boards. The robust frame and advanced temperature processing techniques of Eagle 60 ensure consistent temperature control and a high-quality, high-precision bond every time. The central heating element ensures uniform heat distribution and uniform thermal anvil surface temperature within the bonding area. The built-in camera provides a live visual feedback of the bonding process, enabling optimal process control and accuracy. ASM Eagle 60 utilizes a precise Capillary Feed System (CFS) to draw up wire leads from the spool and feed them to the bonding zone. The CFS has a precision take-up arm to ensure a smooth and accurate wire feed, a wire nozzle to ensure accurate and consistent wire placement, and a wire tension system to keep the wire taut and consistent. Eagle 60 also includes an intelligent wire feeding algorithm, which calculates an optimal dwell time to ensure the wire is kept in the optimal position during the bonding process. ASM Eagle 60 also includes an integrated wire spooler for easy feeding and retrieval of wire reels. The wire libraries in Eagle 60 allow users to store and recall stories of regularly used wire feeds for efficient production. Additionally, the automatic wire cut-off feature allows for the bonding of multiple pieces of wire without having to manually cut them, resulting in a faster, more efficient process. ASM Eagle 60 is equipped with electronic control capability for pre-programmed procedure settings and for the operation of feature capable devices, such as a vision system. For faster, more efficient production runs, automatic placement routines can also be set up for positioning of the wire leads at the contact points of the circuit board. This bonder is also suitable for bonding multiple wires to a single contact point, by controlling individual thermocouples. Overall, Eagle 60 is an advanced wire bonder that offers superior temperature control, speed, accuracy, repeatability, and advanced post-bonding features. It is ideal for production processes of printed circuit boards, and is suitable for precision bonding of single and multi-wire harnesses. This bonder can help ensure consistent quality results on a variety of products and applications.

There are no reviews yet