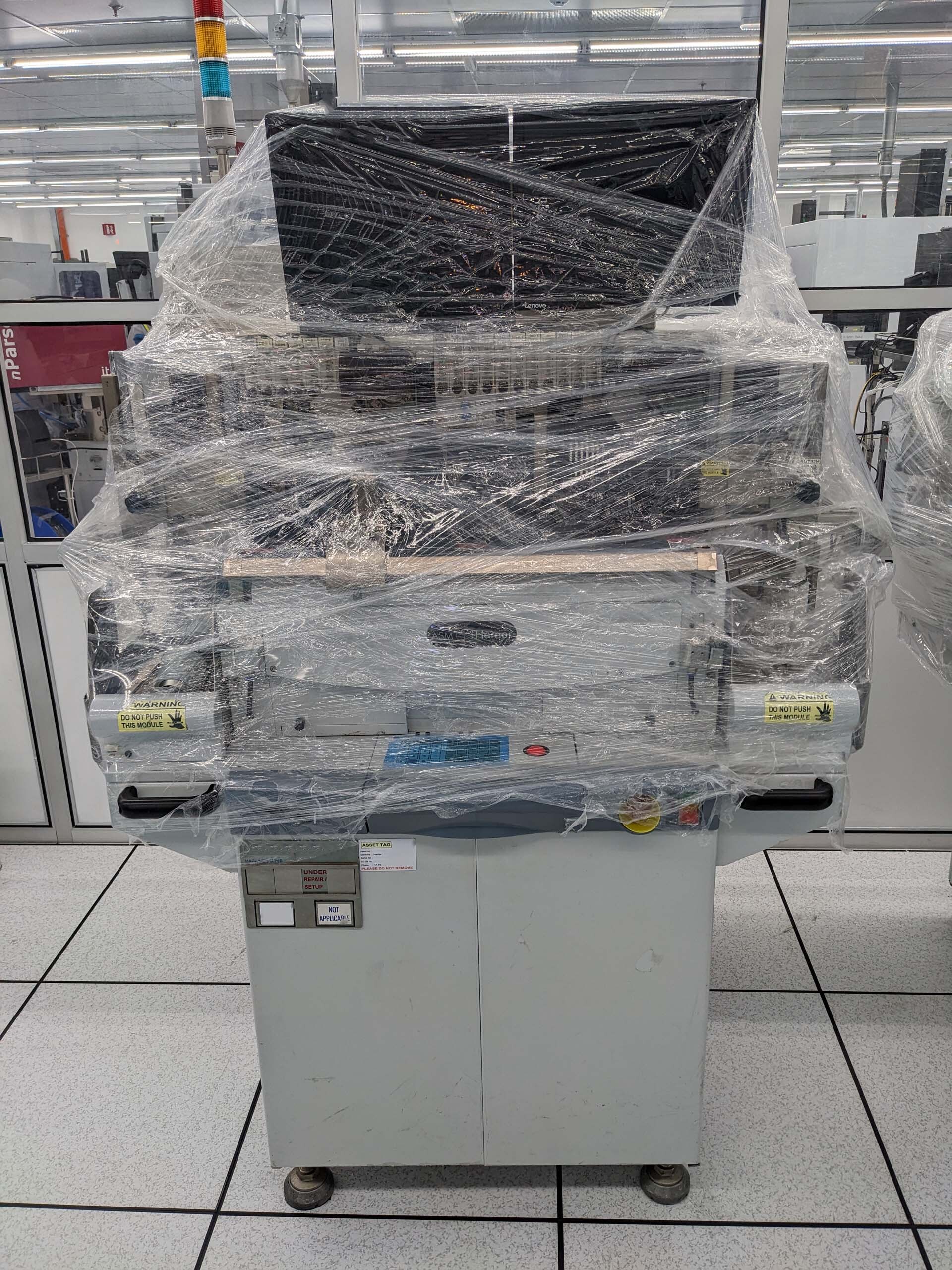

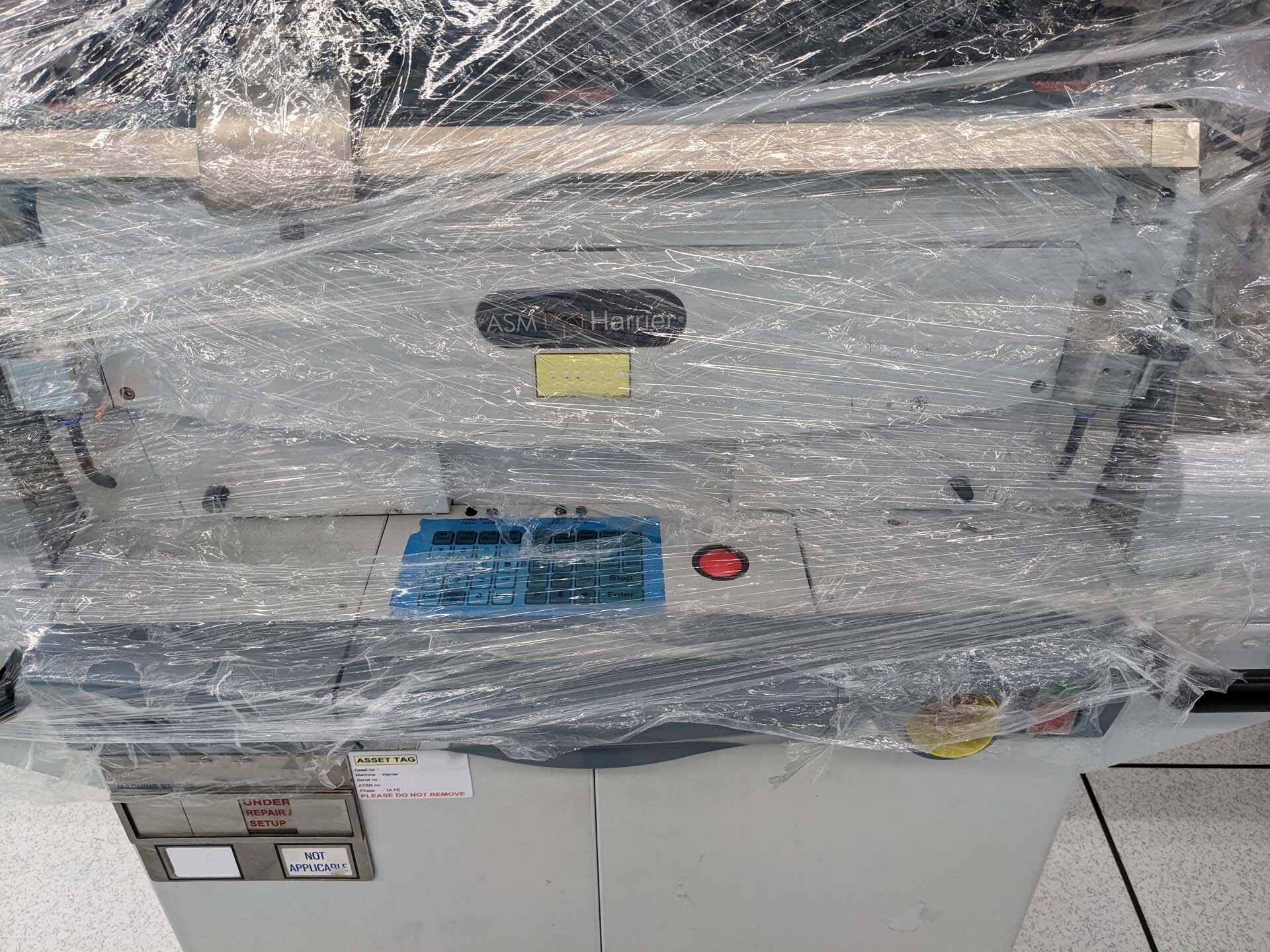

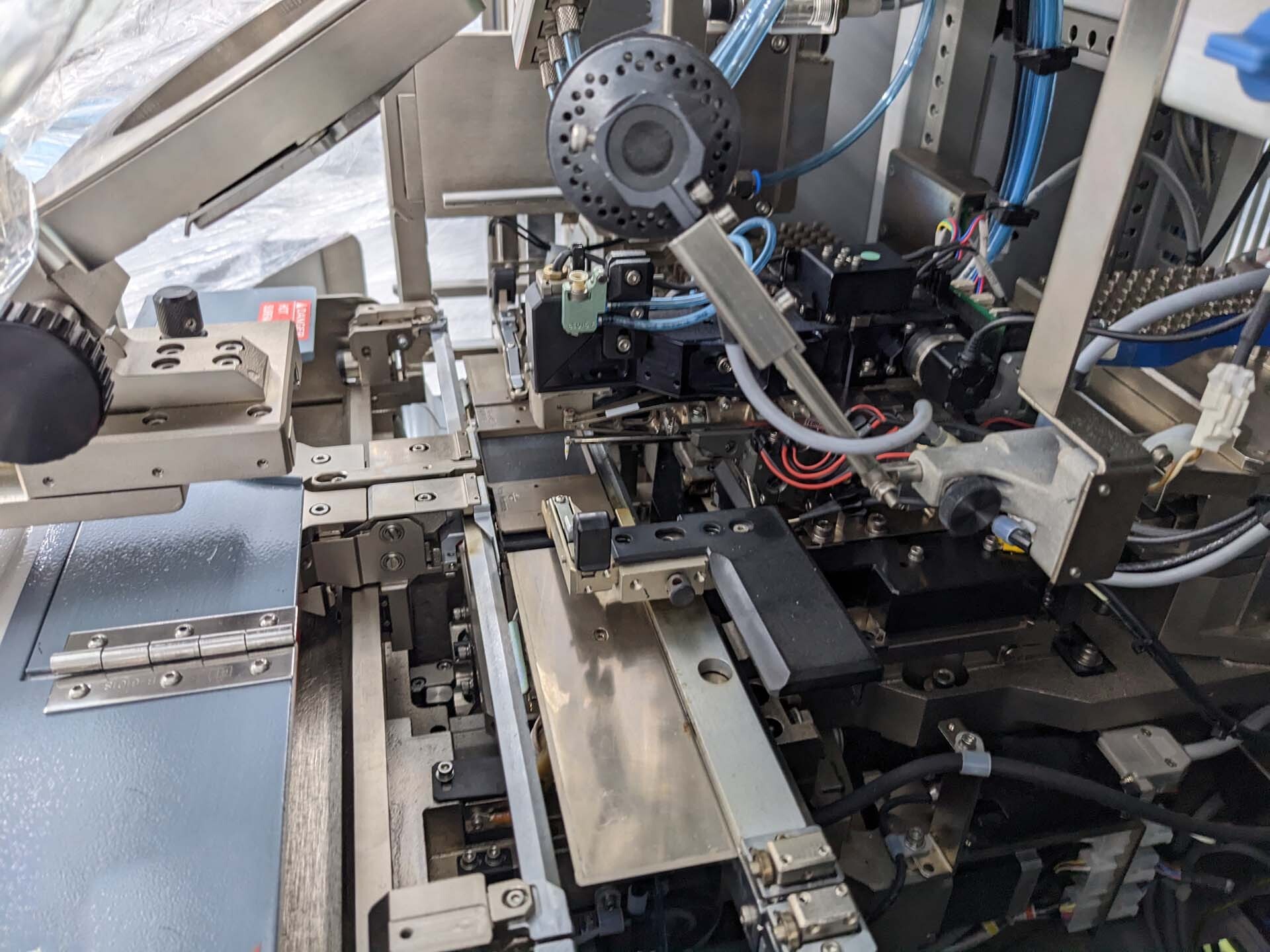

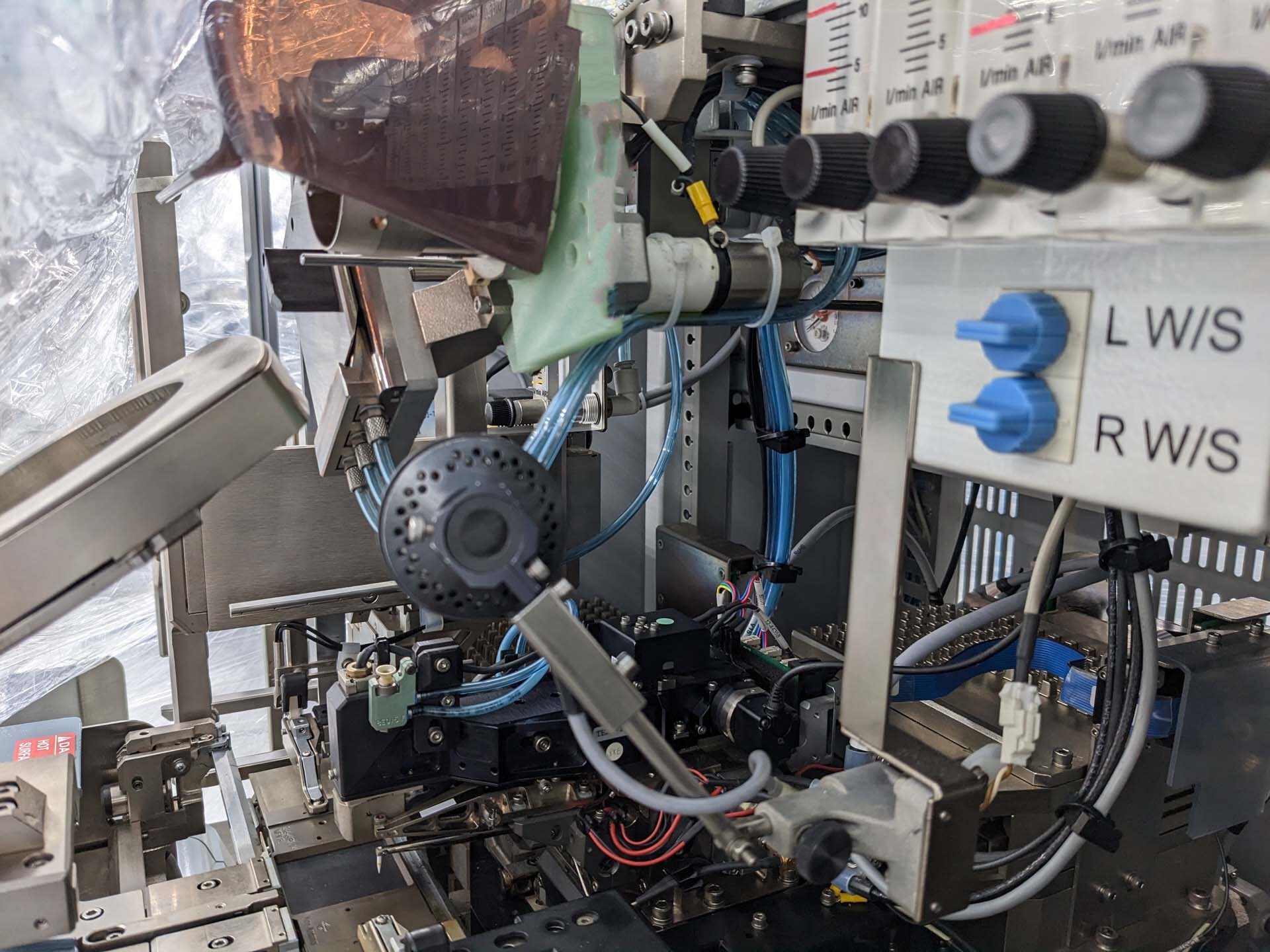

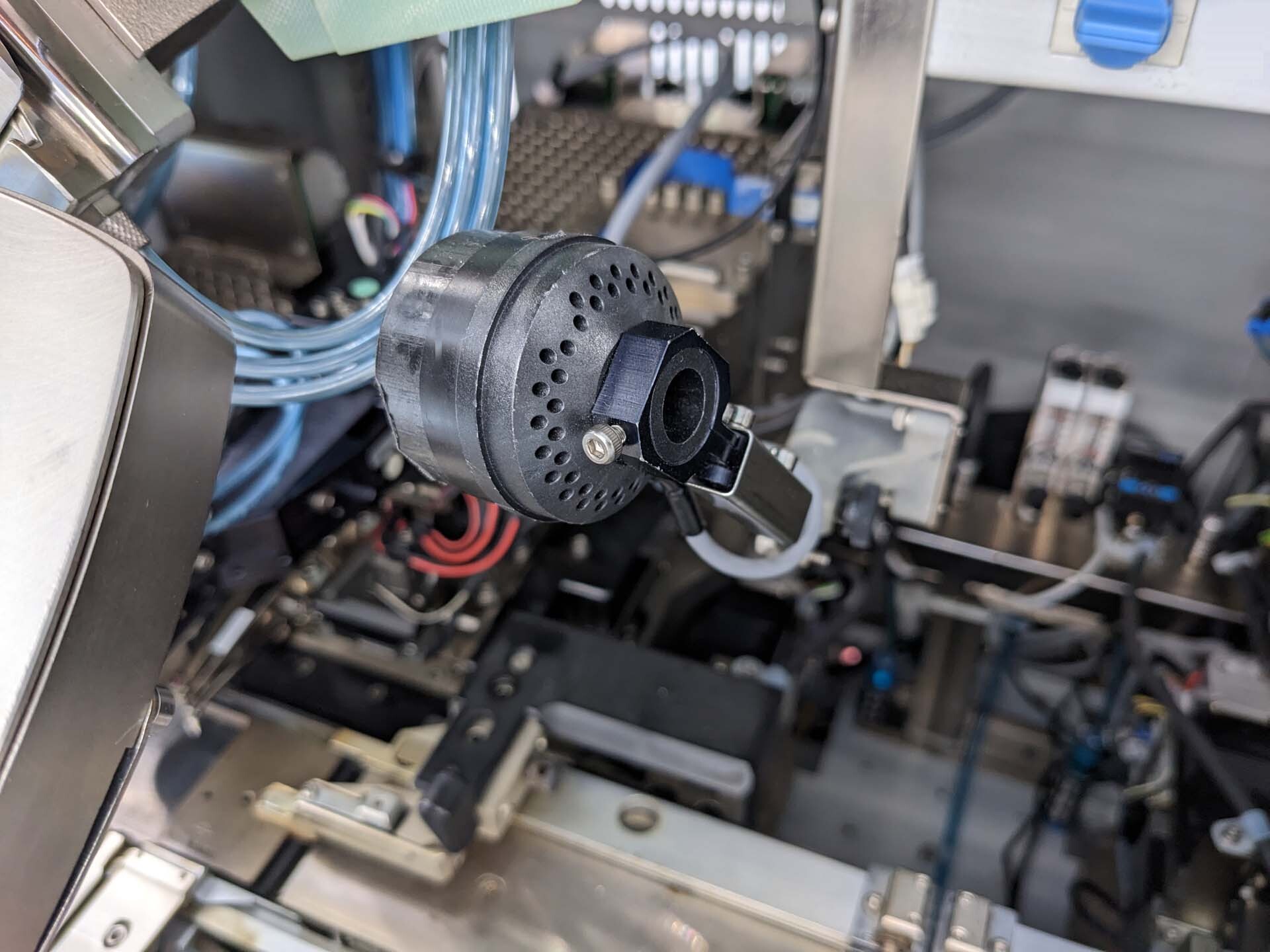

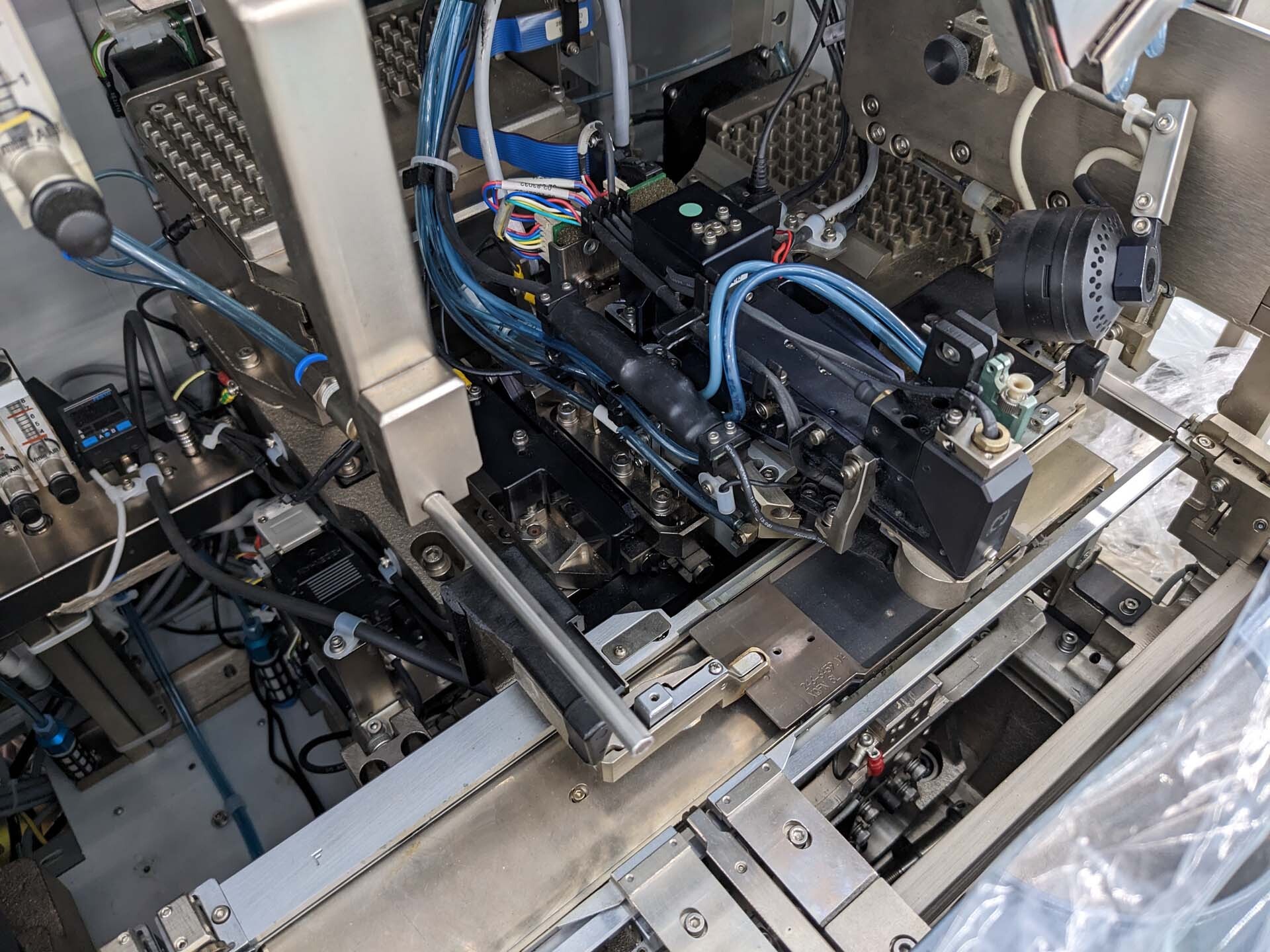

Used ASM Harrier #293661120 for sale

URL successfully copied!

Tap to zoom

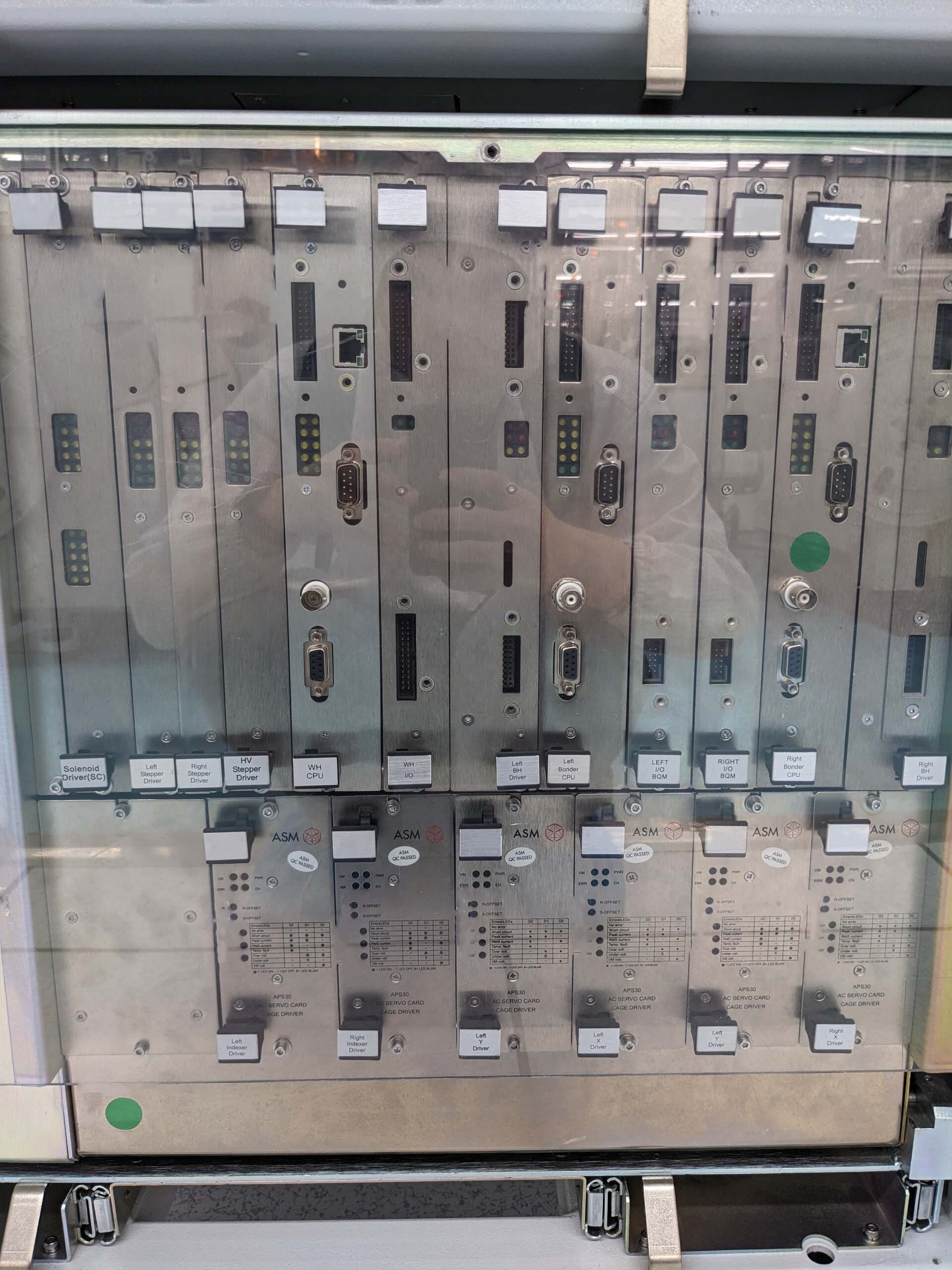

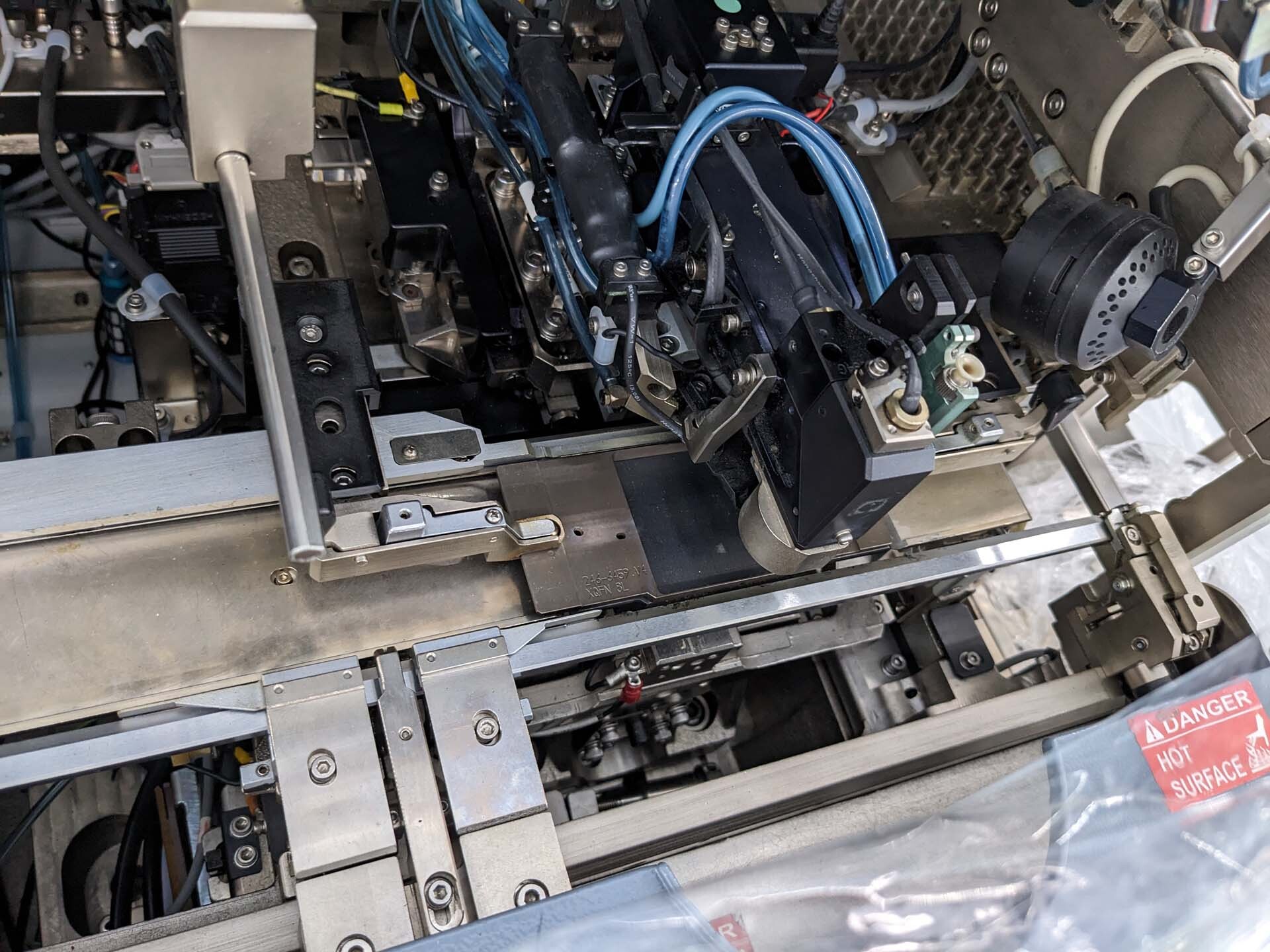

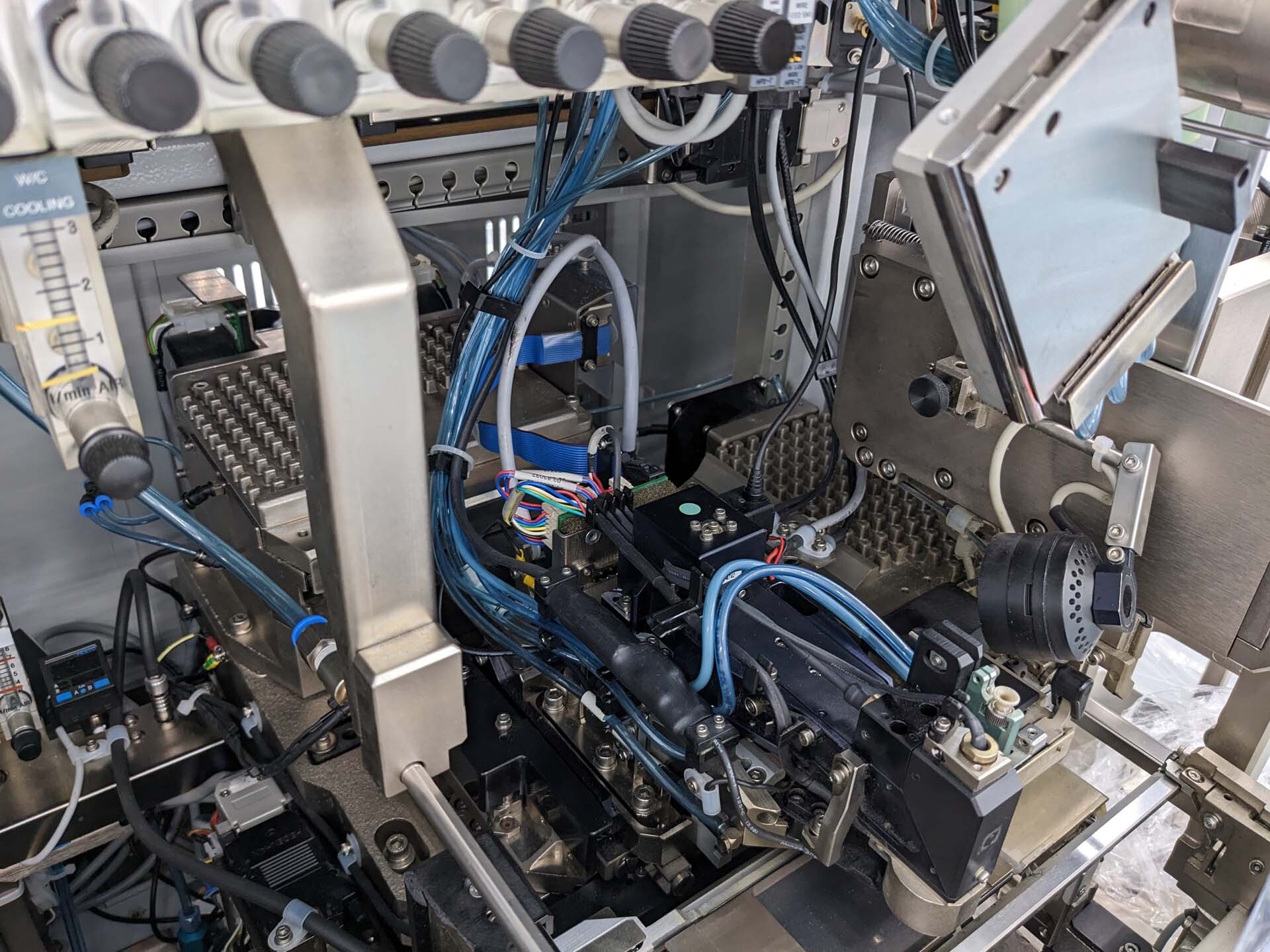

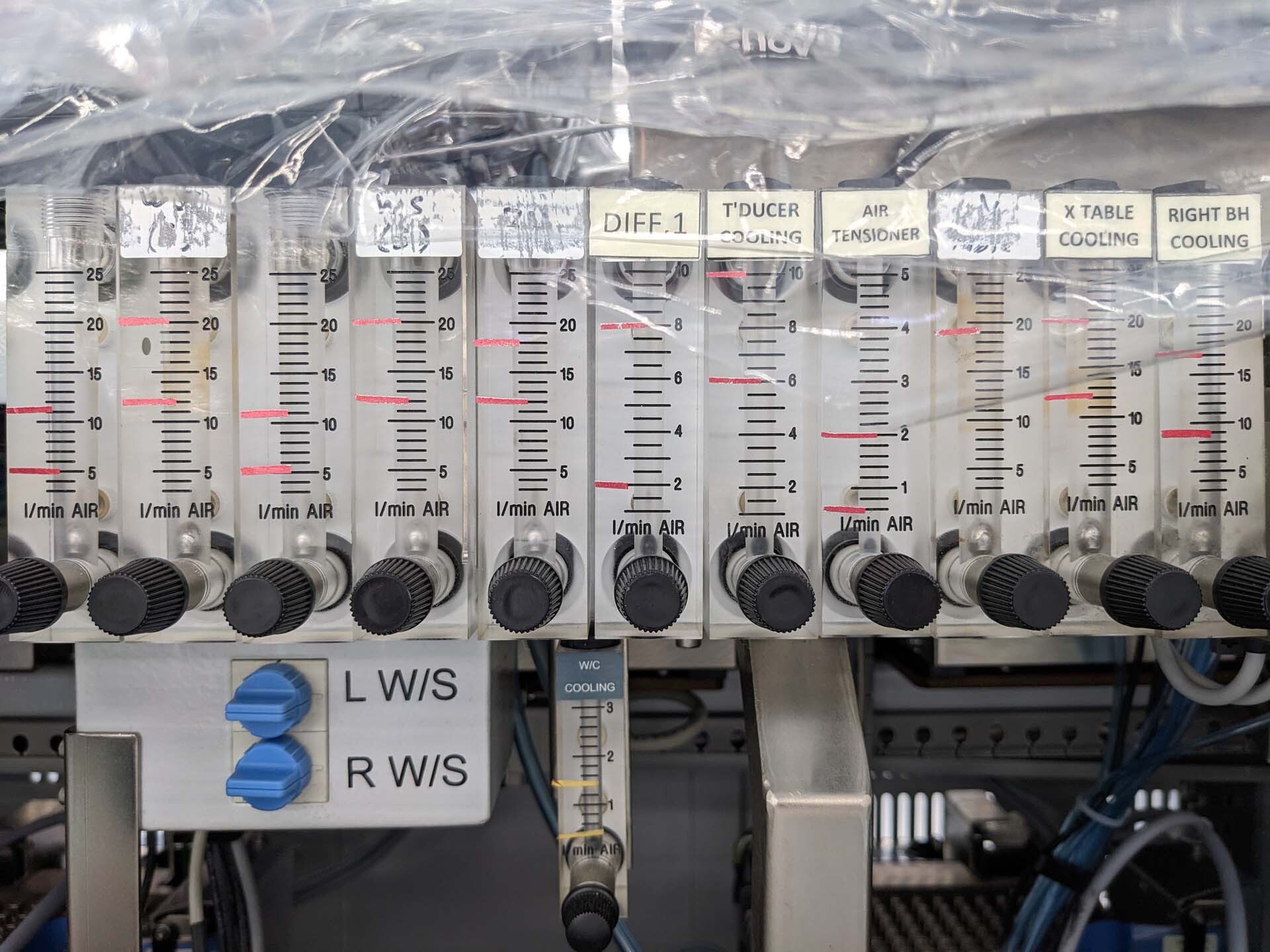

ASM Harrier is an advanced automated bonding equipment which is capable of assembling and packaging products with increased efficiency and precision. The system is designed to meet the needs of diverse production facilities, with its highly configurable design allowing it to quickly adapt to changing production requirements. Harrier consists of three core components: a main control unit, a needle assembly module and a needle scanner unit. The main control unit is the brains of the machine, featuring a powerful Intel i5 processor, 16-gigabyte RAM, and a 500 GB HDD for storing data. The needle assembly module houses a wide array of needle configurations, including wire straighteners, crimpers, presses, and die sets, allowing ASM Harrier to quickly switch between different applications. The needle scanner tool utilizes cameras and lasers to precisely control position and angle of the needles, eliminating the need for manual adjustment. Harrier is designed for complete flexibility and customization, allowing for a wide range of production materials and product designs to be catered for. This includes metal, plastic, and composite components, and product modules ranging from wrist watches to medical devices. The asset is extremely simple to integrate with existing production systems, and can be controlled, monitored and tracked via its intuitive touch-screen interface or through custom software integration. ASM Harrier is designed to optimize production speeds and ensure consistently high product quality. Its needle-acquisition accuracy is up to 0.5mm, and its repeatability is tracking at 0.1mm, making it ideally suited for precision applications. It can execute electro-mechanical bonding operations at speeds up to 1000 cycles/minute, and can easily be programmed to switch between different needle configuration for multiple bond types in a single operation. Harrier is an ideal choice for applications requiring reliable and consistent production, with its highly configurable design making it suitable for multiple industries. Its robust structure and comprehensive safety features make it a good choice for high volume production. This automated bonding model delivers precision and accuracy in a cost-effective package, revolutionizing modern manufacturing operations.

There are no reviews yet