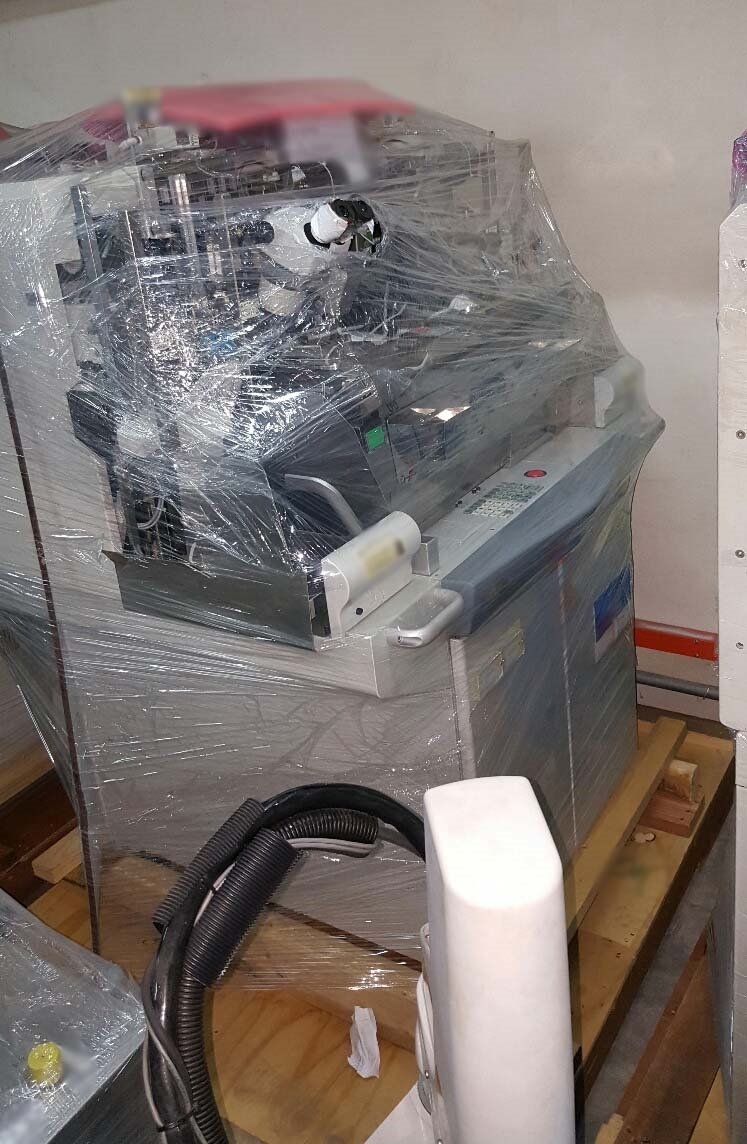

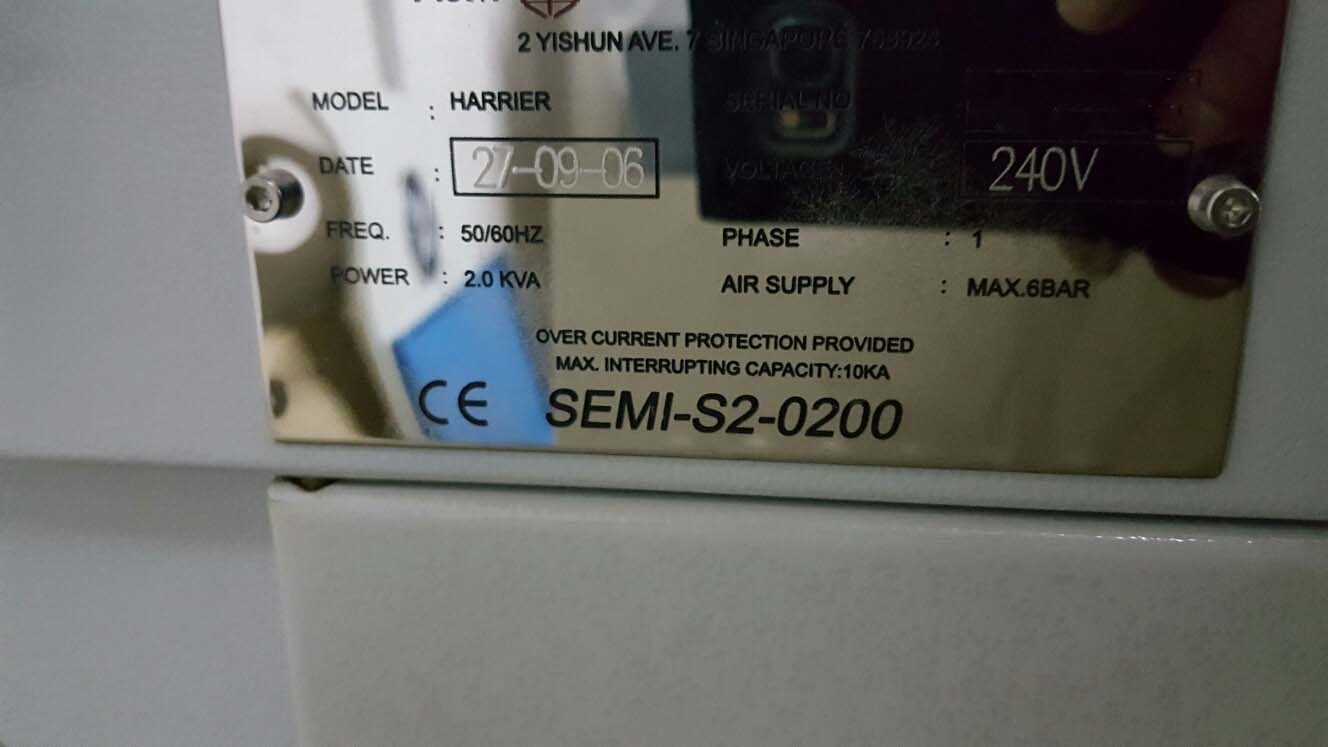

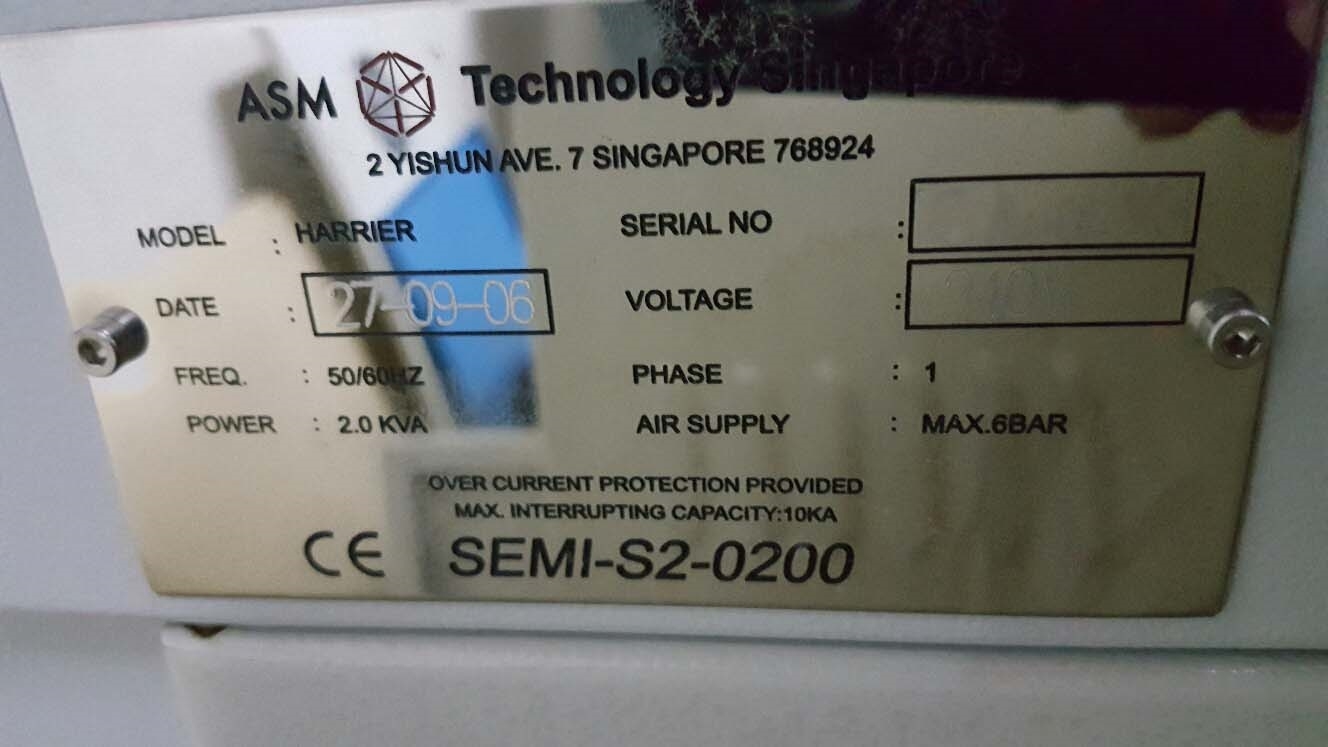

Used ASM Harrier #9204611 for sale

URL successfully copied!

Tap to zoom

ASM Harrier is an advanced surface mount (SMT) bonder designed for high accuracy and repeatability. It is a fully automated equipment designed for various types of applications, such as surface mount, chip-on-board (COB), and CSP mounting. Harrier utilizes its high-performance vision system, advanced pattern recognition, and flight control algorithms to ensure accurate placement of components every time. It consists of dual-thermal lasers, a CCD camera, a 3-D placement head, and pneumatic and vacuum systems for moving, lifting, dispensing, and bonding. The dual-thermal laser beam delivers excellent heat transfer, while its minimized heat spot size ensures accurate and repeatable placement of the component. The CCD camera facilitates accurate alignment of components and the 3-D placement head ensures fast and precise placement. ASM Harrier has a user-friendly interface and it can be integrated with computer-aided-design (CAD) software to load and process patterns. The machine can also be used for advanced vision-inspection applications, such as defect detection, as well as for automated fine-pitch soldering. The machine is also capable of handling a variety of substrates, including ceramic, paper polymer, and aluminum substrates. Furthermore, it comes equipped with an easy-to-use human-machine interface that provides intuitive guidance and feedback. The machine runs on a user-friendly Windows operating unit and provides detailed feedback on the process. Harrier offers high speed and productivity. It offers repeatability of +/-50 micrometers and a placement speed of up to 400 components per minute. Furthermore, it can handle components with a size range of 0402 to 3555 and a minimum package size of 0.2 mm x 0.1 mm. The high-performance machine not only speeds up production but also reduces costs. ASM Harrier is highly reliable and offers improved safety and longevity, as well as a smaller footprint. It is compatible with a wide range of materials, making it ideal for a variety of industries, including consumer electronics, automotive, aerospace, and medical. The machine is also cost-effective and provide a great return on investment.en

There are no reviews yet