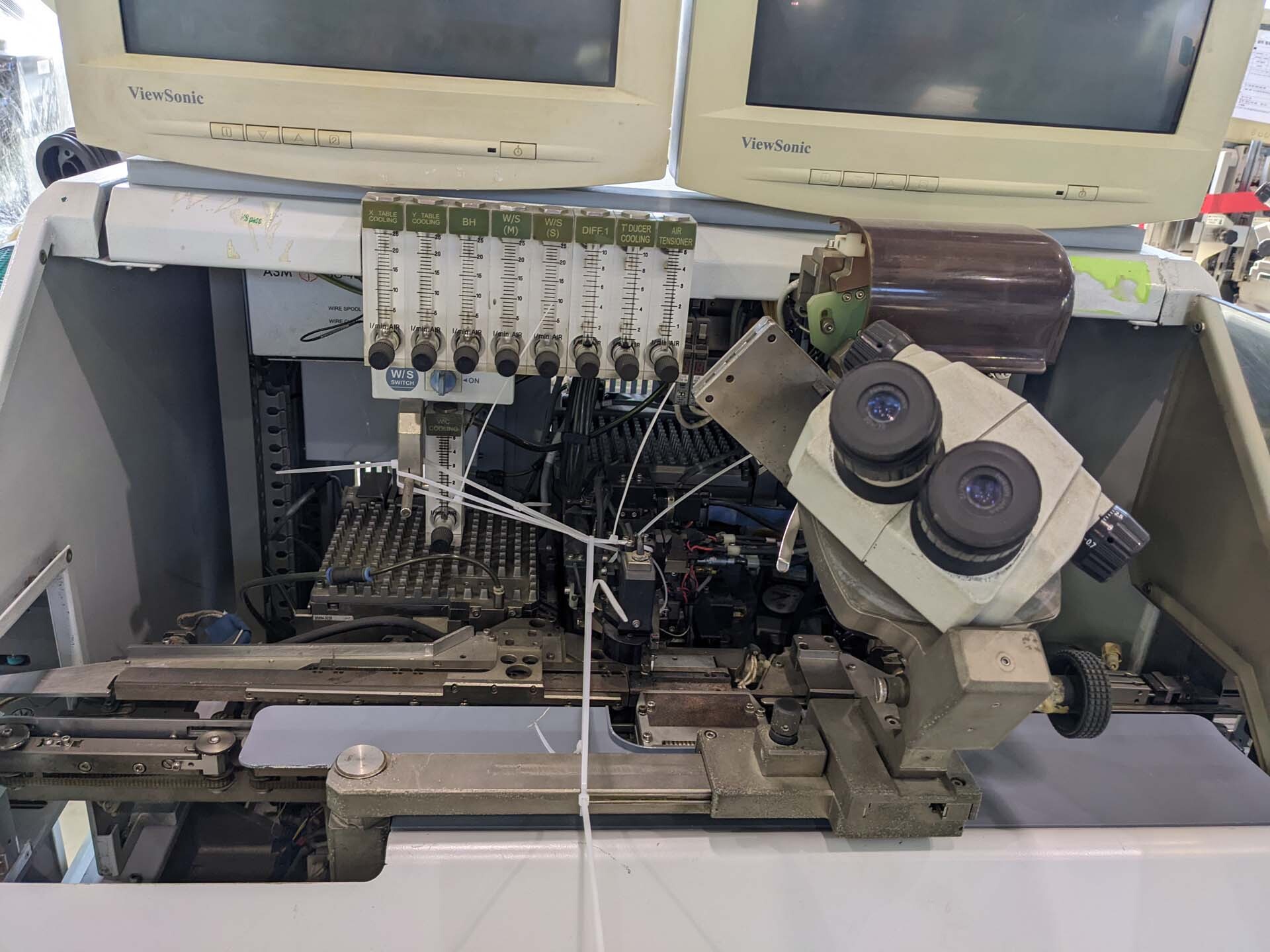

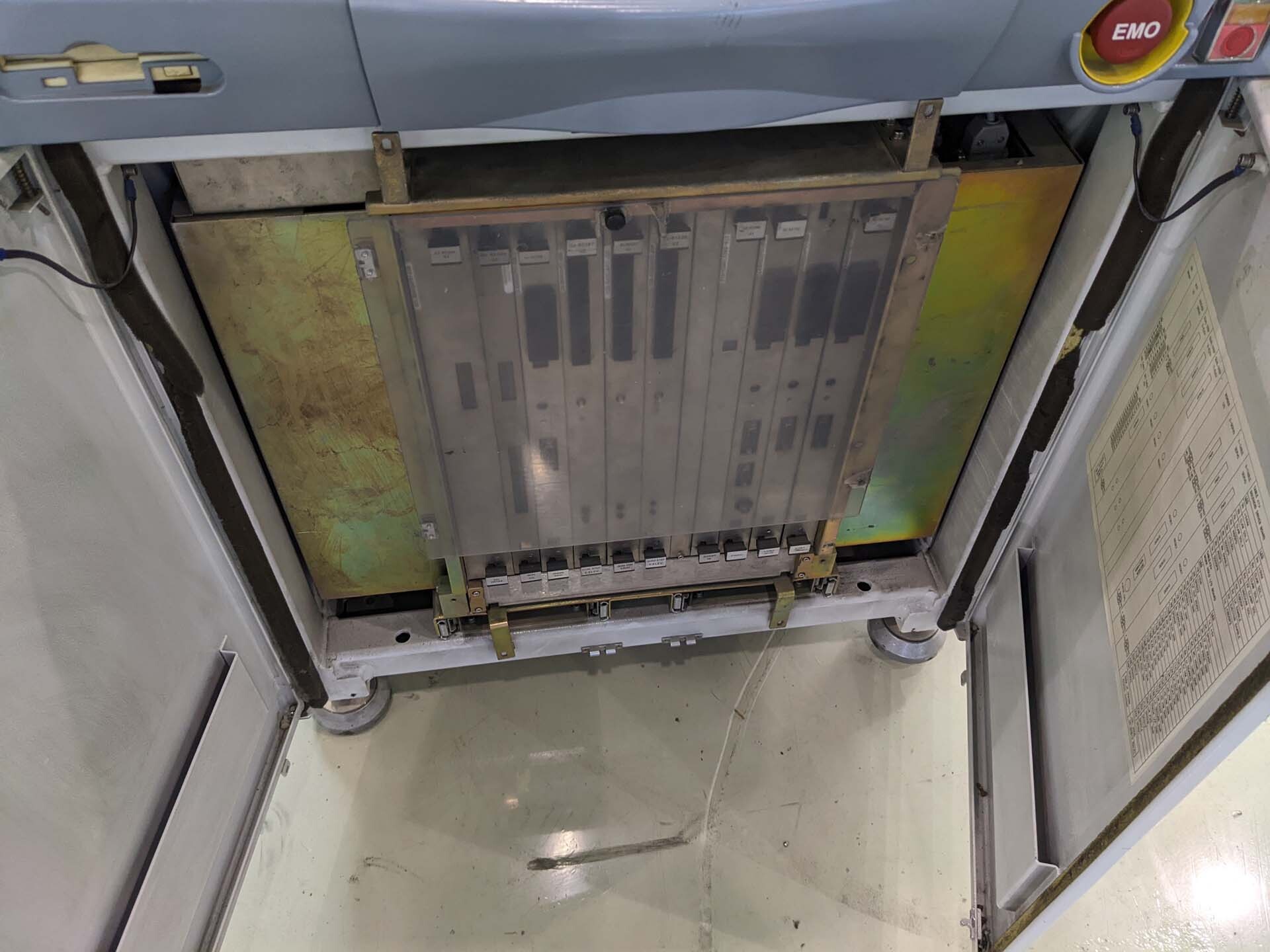

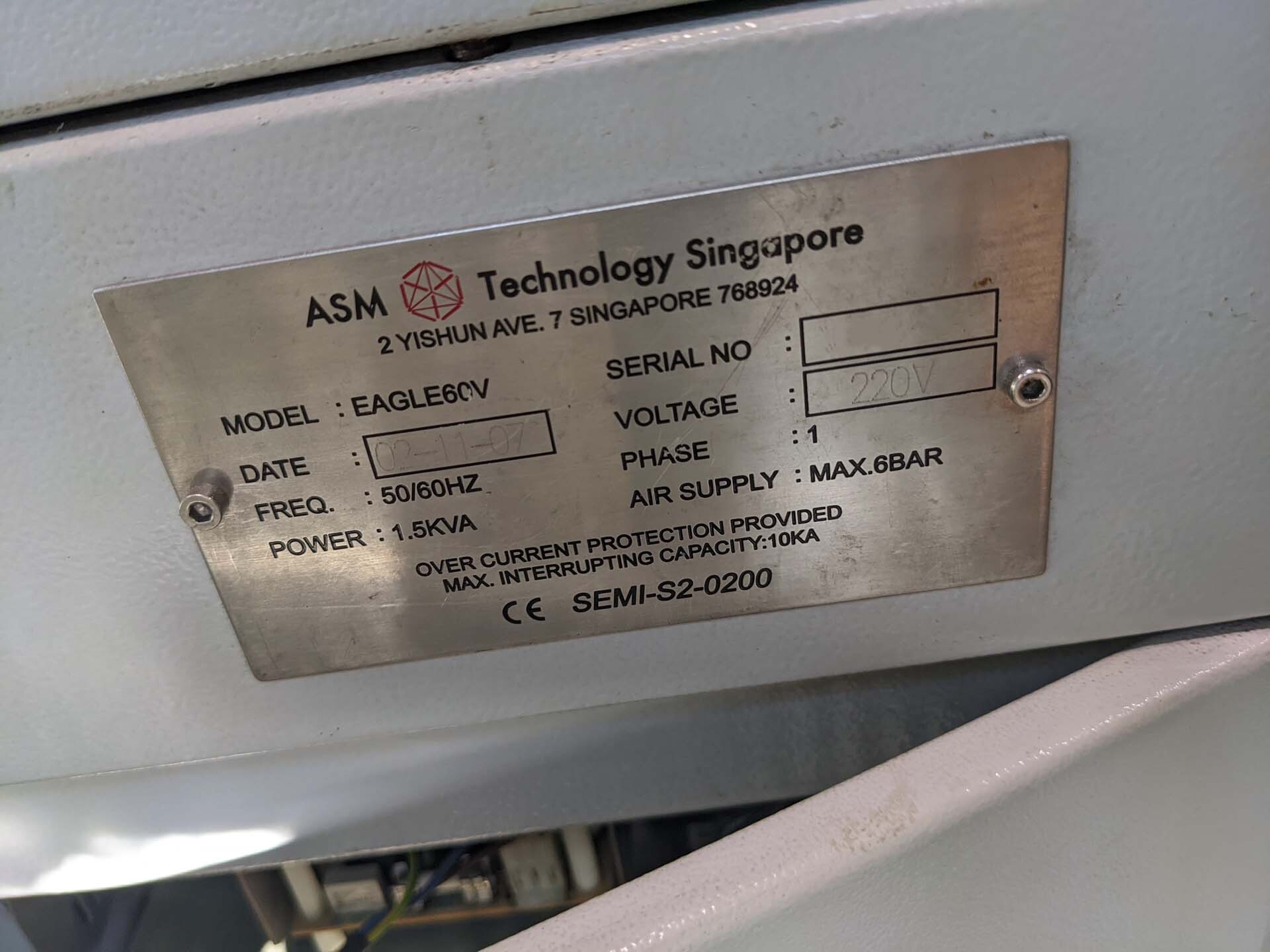

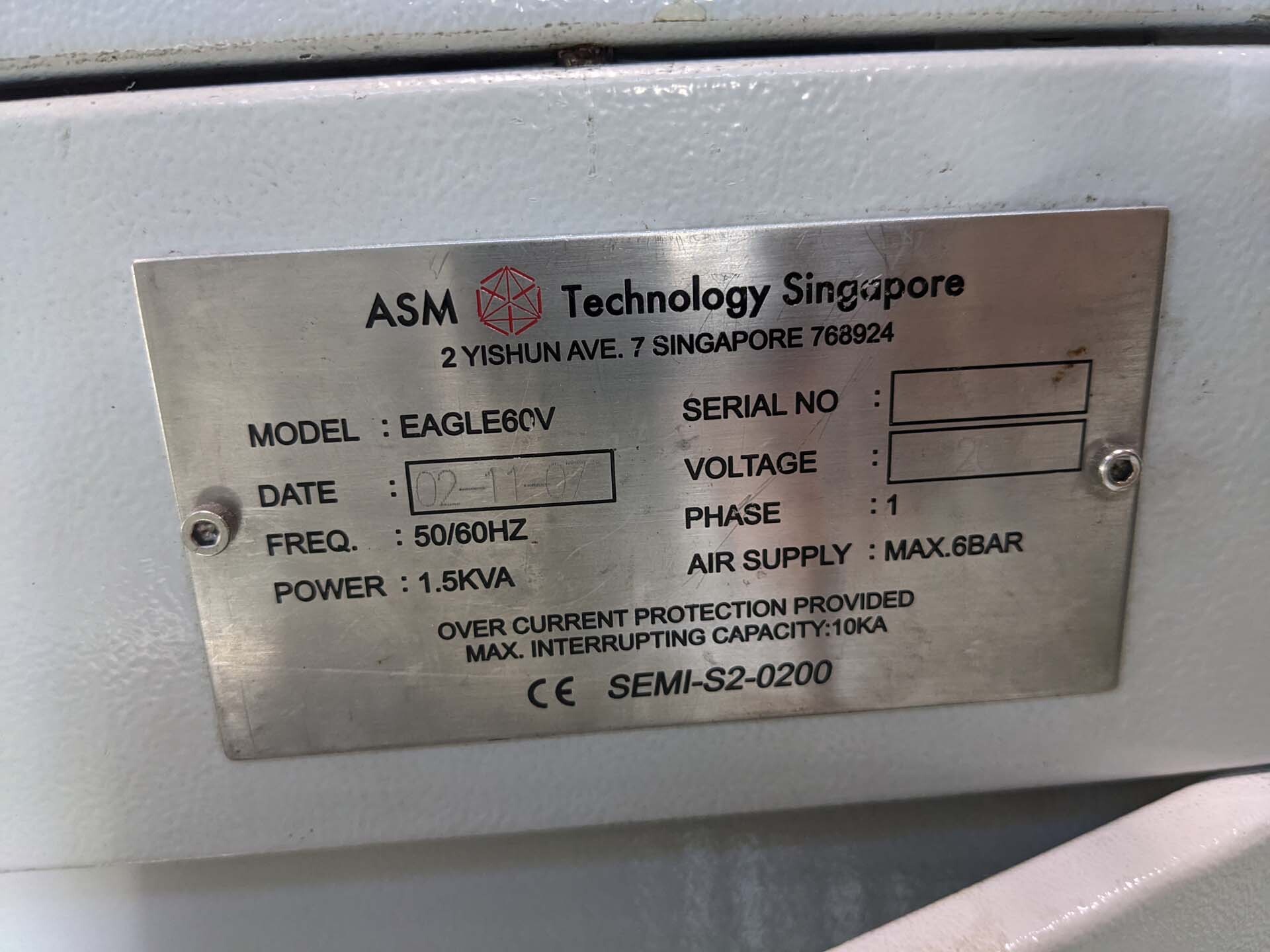

Used ASM iHawk V #293635005 for sale

URL successfully copied!

Tap to zoom

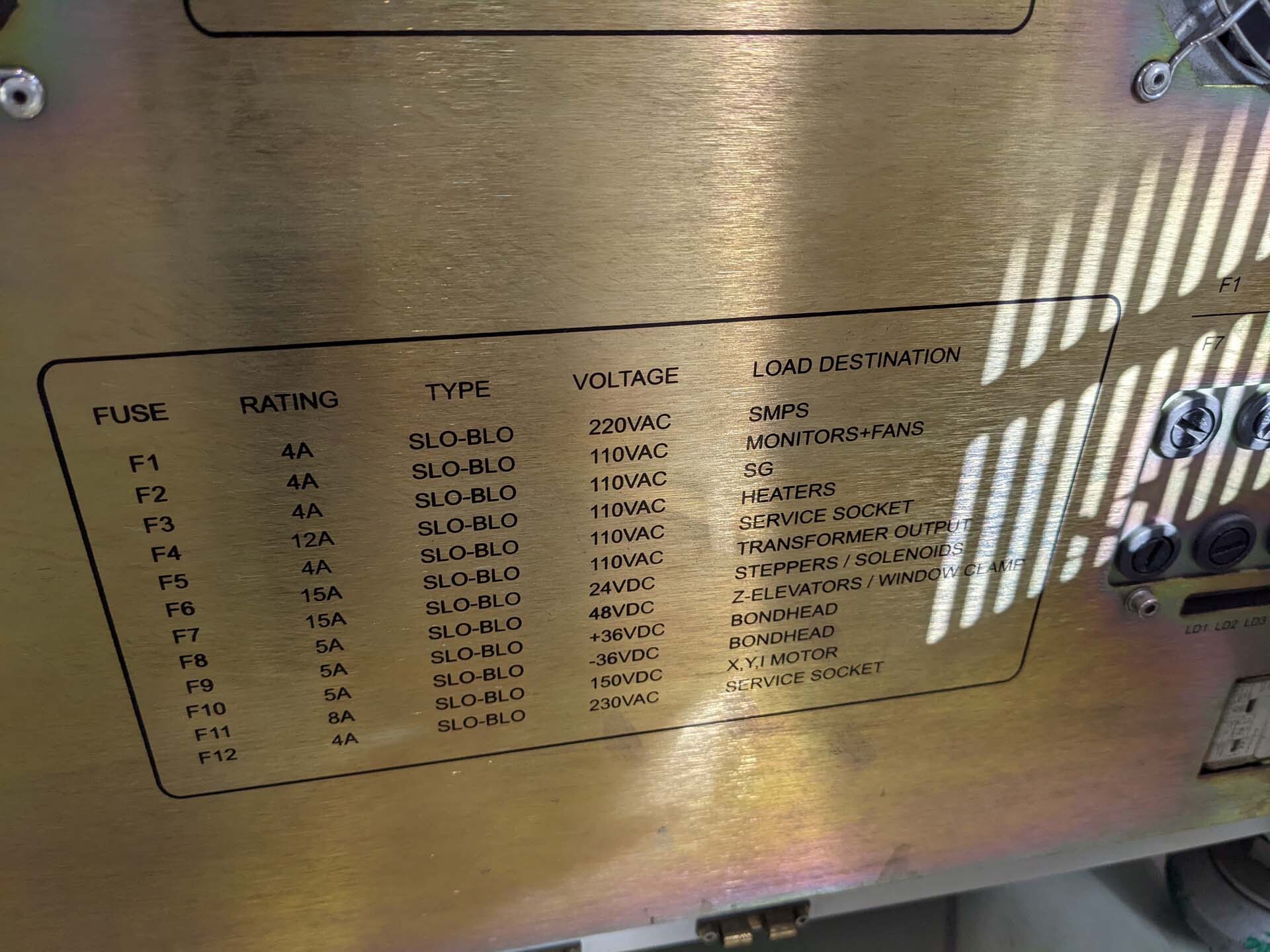

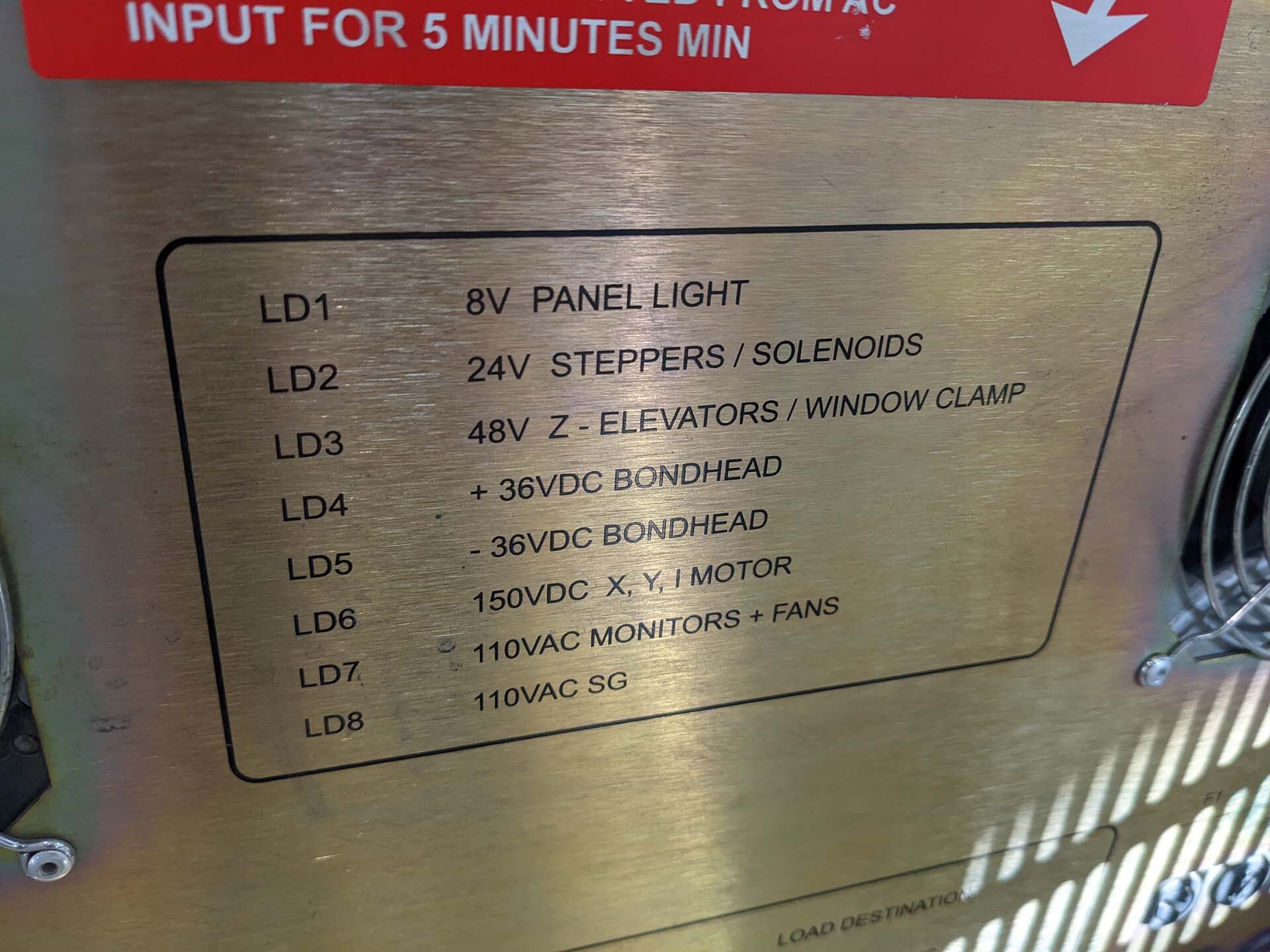

ASM iHawk V is a state-of-the-art bonder developed by ASM International, Inc. Its groundbreaking technology makes it the perfect solution for efficient and reliable heating and bonding of metals, ceramics, and other materials. The bonder has a unique four-axis design, with each axis controlling the heating, bonding, and finishing processes. The built-in X-axis provides precise and consistent bonding of materials, while the Y-axis is used to apply pressure to the bond. The heated probes are then precisely adjusted by the Z-axis for precise and consistent bonding. The fourth axis is used for determining the speed and direction of the finish operation. IHawk V features an intuitive touchscreen interface for access to the device's full range of features and settings. The powerful internal database allows for easy access to recipes, diagnostics, and more. Additionally, a wide range of accessories can be connected to the device, such as vacuum pumps, temperature probes, and pressure regulators. To ensure safety and reliability, ASM iHawk V is equipped with an insulation system that prevents overheating, as well as a self-calibration system to maintain consistent temperatures and pressures. The automatic correction of the pressure and temperature parameters also helps to ensure repeatable and reliable results. IHawk V comes with a variety of thermal bonding tips that are suitable for different types of materials. These tips are compatible with the device's high-precision traversing movement mechanism, which ensures that the bonding is accurate, even for complex applications. The bonder is designed for easy integration into production lines and manufacturing processes. With the ability to interface with custom-made machines and other automation systems, ASM iHawk V can be effectively used in a wide variety of production environments. Overall, iHawk V is an advanced and reliable bonder. Its precision and repeatability helps to ensure accurate, reliable, and consistent bonding of various materials. Plus, its intuitive user interface and extensive range of features make it easy to use and integrate into existing production lines.

There are no reviews yet