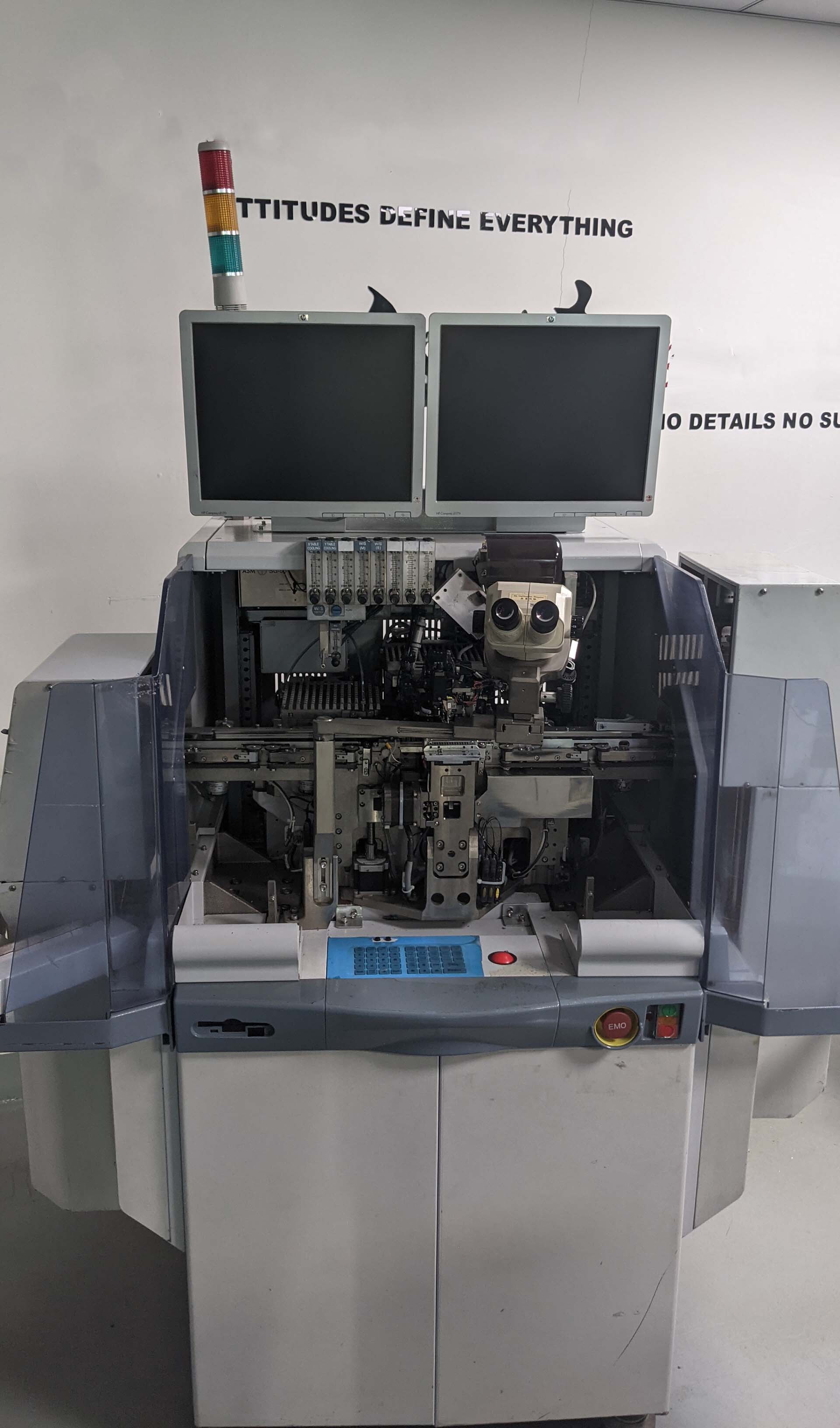

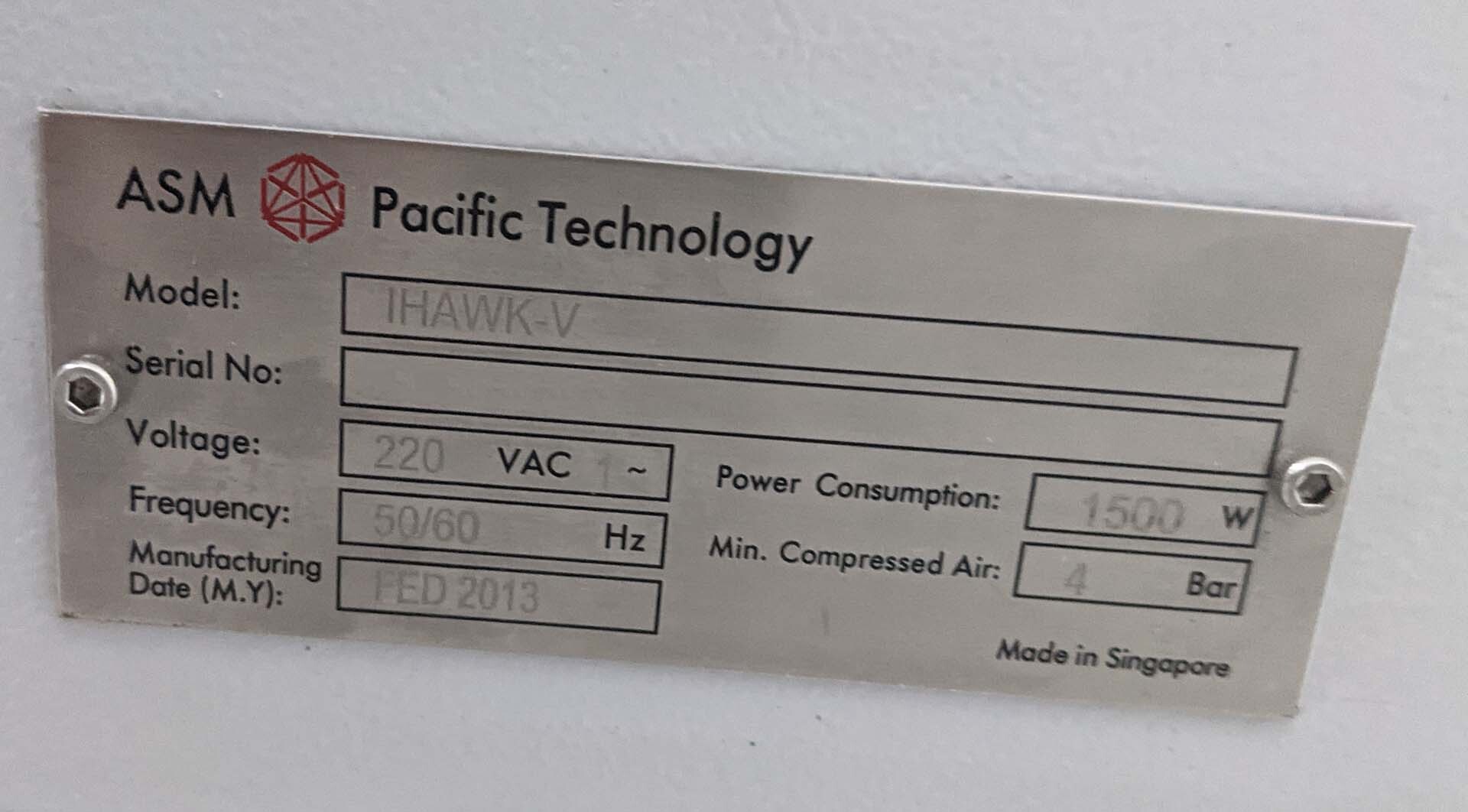

Used ASM iHawk V #9378654 for sale

URL successfully copied!

Tap to zoom

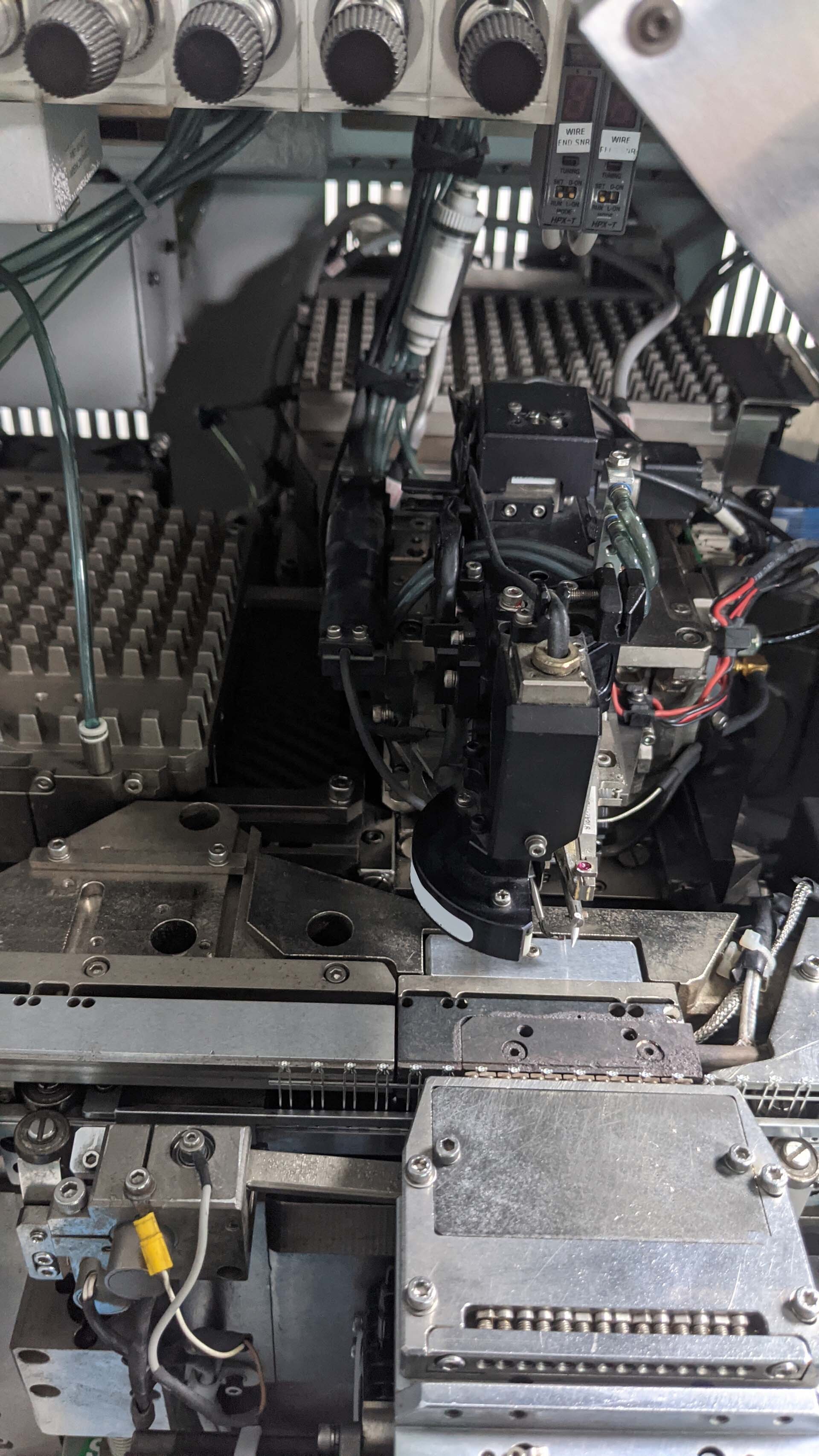

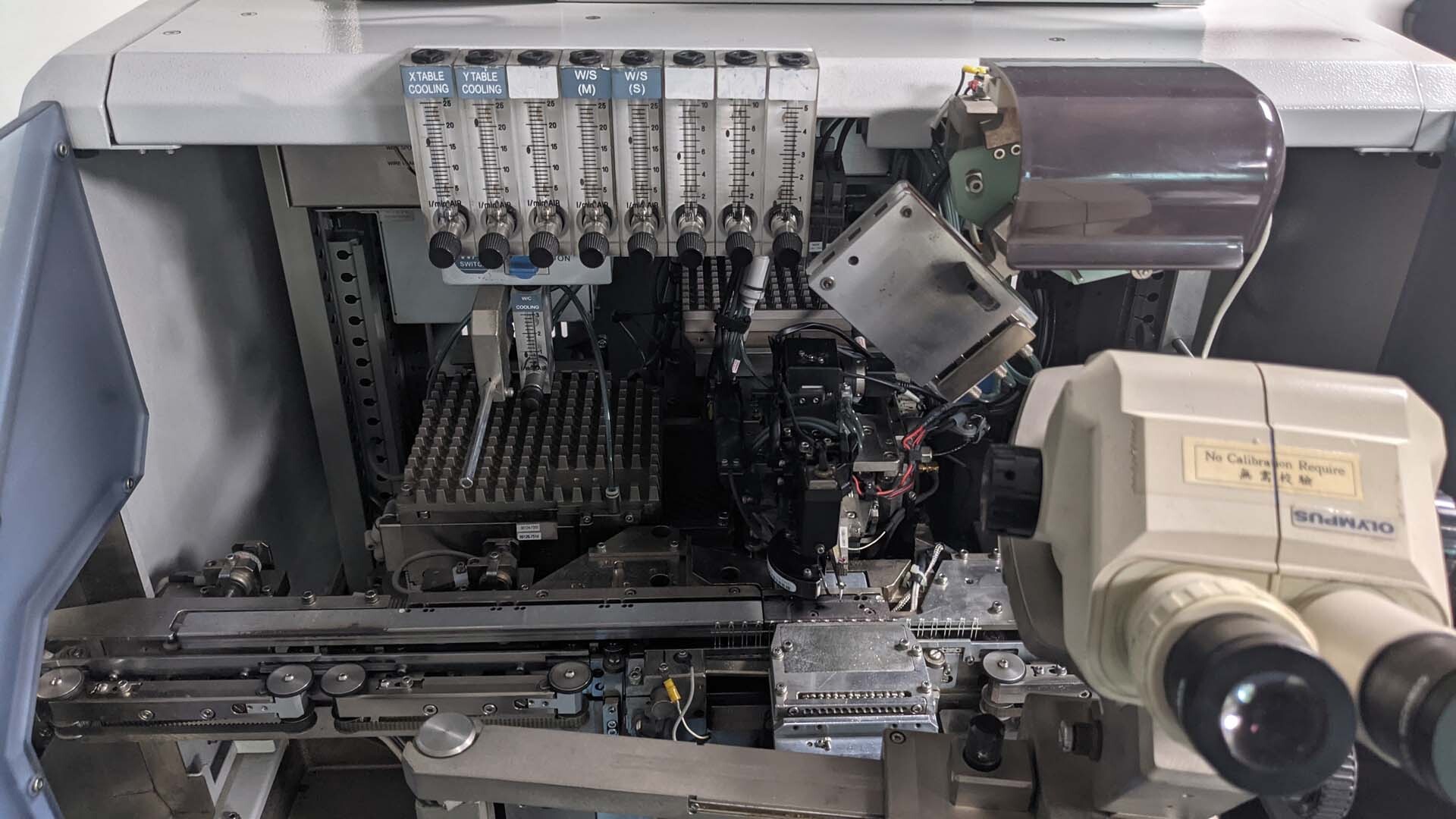

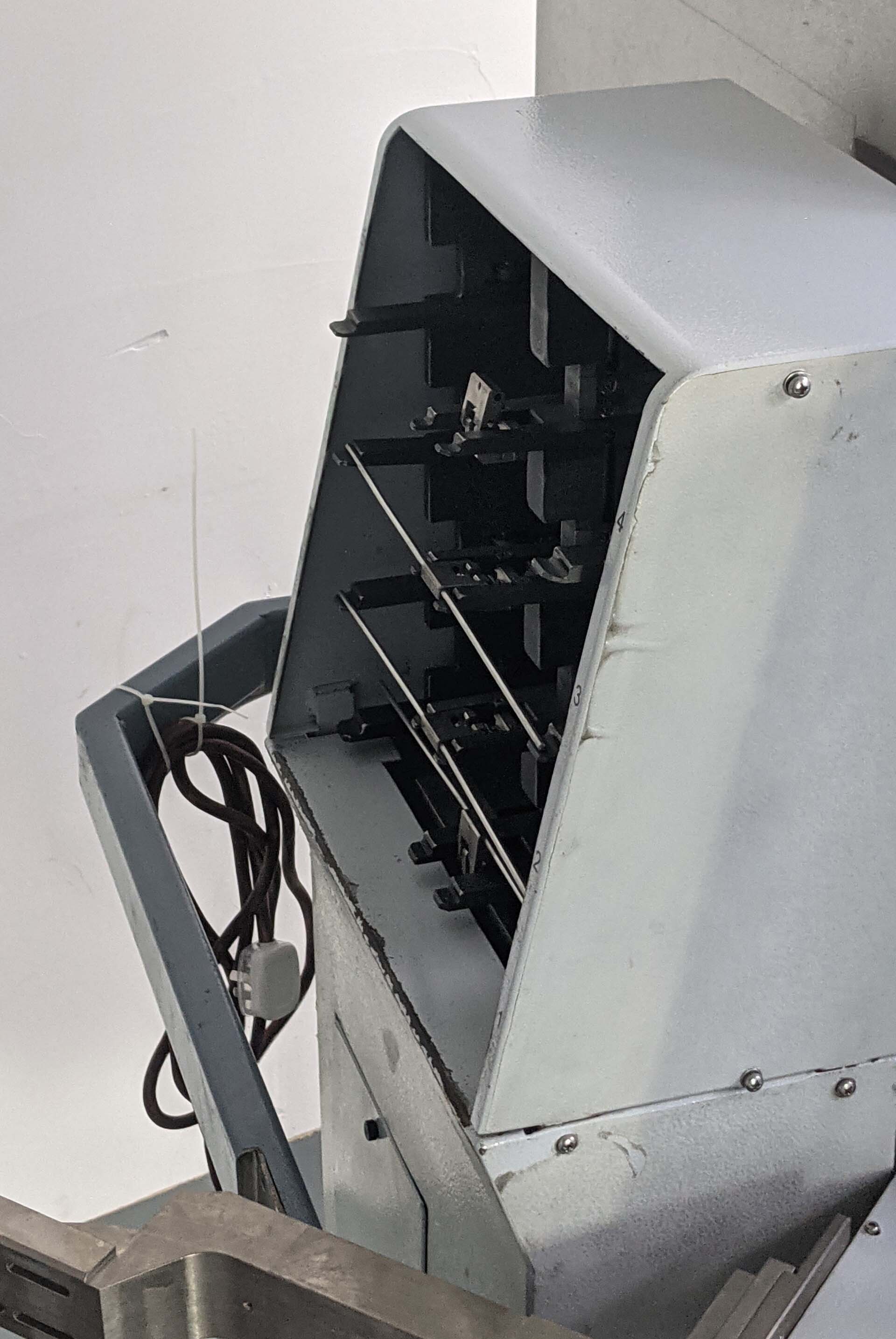

ASM iHawk V Bonder is a state-of-the-art automated wafer and die bonder that is used to attach two separate components together, such as dies to passive substrates, or chips to encapsulated packages. This unique equipment is designed to allow for fast and efficient wafer and die bonding, without compromising electrical and mechanical performance. IHawk V Bonder houses a multi-axis precision arm for precise placement, an infrared optical alignment module for tight tolerances and 3D vision system for automated component location. This bonder also includes two automated pre-bond stages, making it possible to perform both pre-bonding and post-bonding at the same time for increased efficiency. In addition, this bonder is designed with an enhanced safety protocol. It is equipped with dual safety sensor systems that activate if the unit is moved from a pre-determined bonding area or placed in an area that is too tight for it to perform successfully. This ensures that the process remains safe and efficient, while productivity is maximized. ASM iHawk V Bonder also includes several advanced active monitoring and control features to ensure the process runs as efficiently as possible. It has an advanced die-to-die comparison feature for quick confirmation of the bond process. Its defect detection unit also continually monitors the bond process, detecting and logging defects in real time. This information can be used for preventive maintenance, which helps lower costs, reduce waste and improve yields. Finally, iHawk V Bonder is designed for easy maintenance. All of its components, such as the bond head, feeder, motor, and module, can be quickly changed and replaced without having to disassemble the entire machine. This ensures that the bonder is ready for use and maintain its performance. To sum up, ASM iHawk V Bonder is an advanced and reliable automated machine for die and wafer bonding. It offers a reliable and safe bonding process utilizing advanced control and monitoring systems. Furthermore, it has easy maintenance features, which allows users to easily change parts and keep the bonder performing at its best.

There are no reviews yet