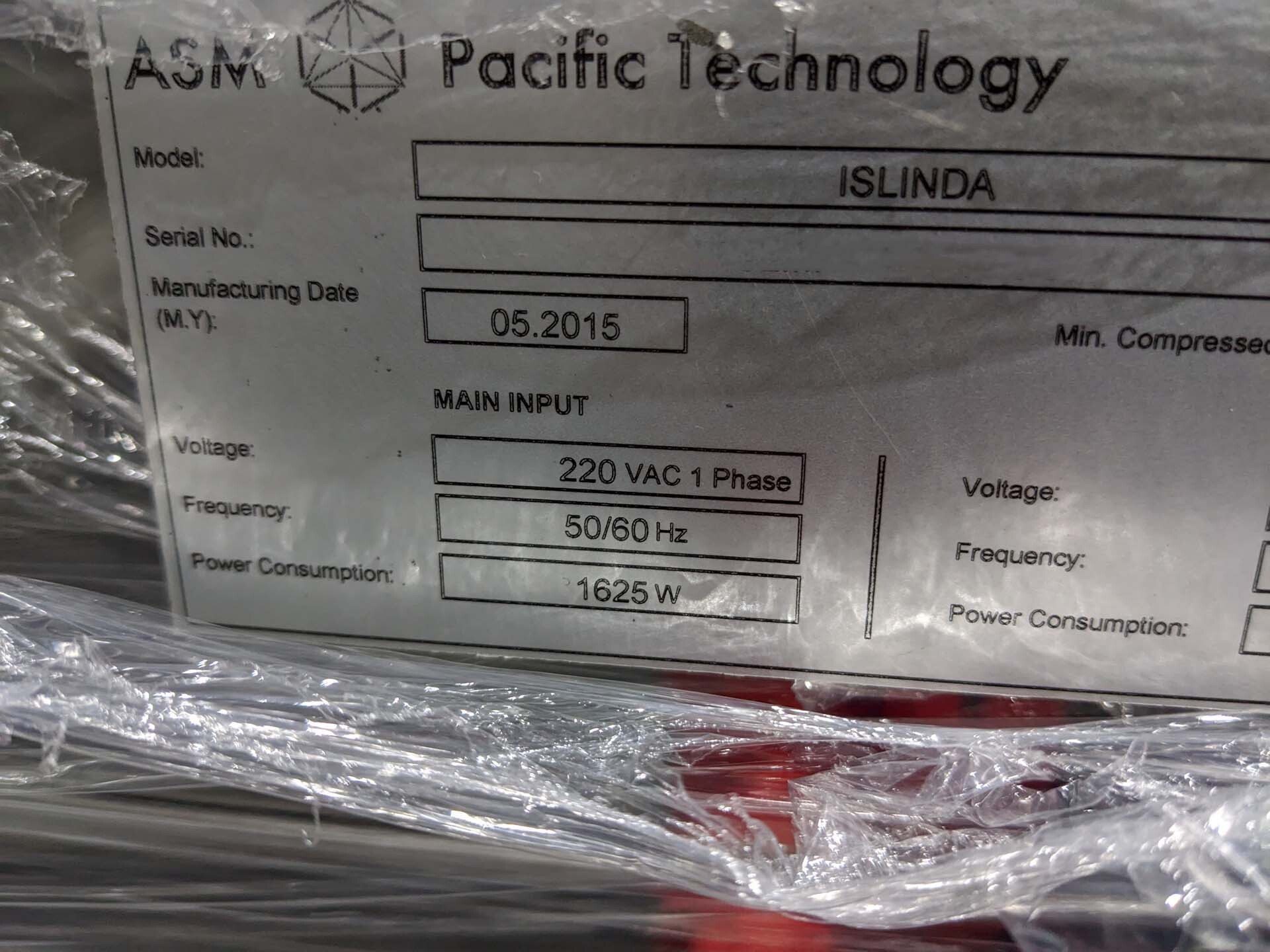

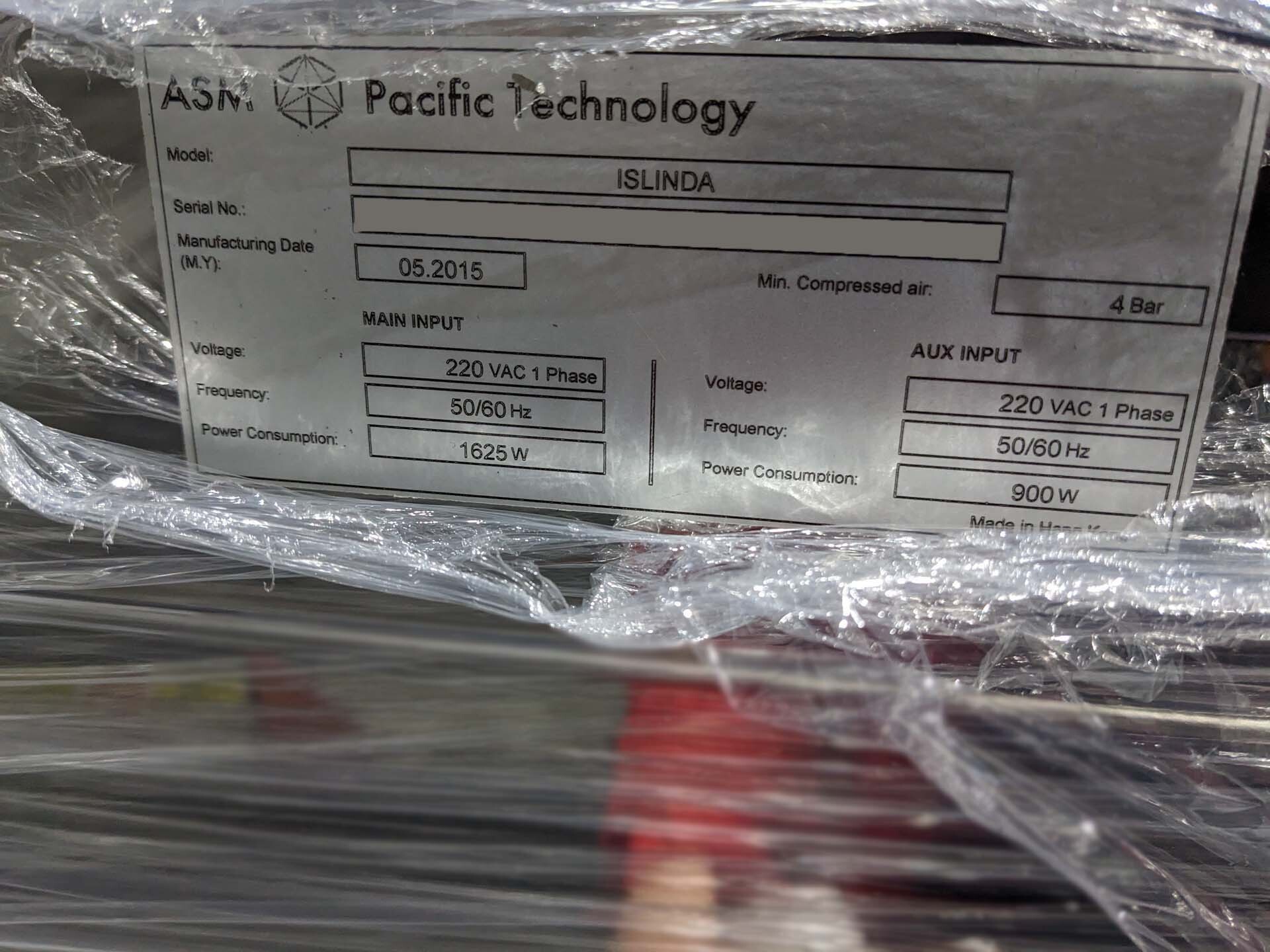

Used ASM ISLINDA #293624583 for sale

URL successfully copied!

Tap to zoom

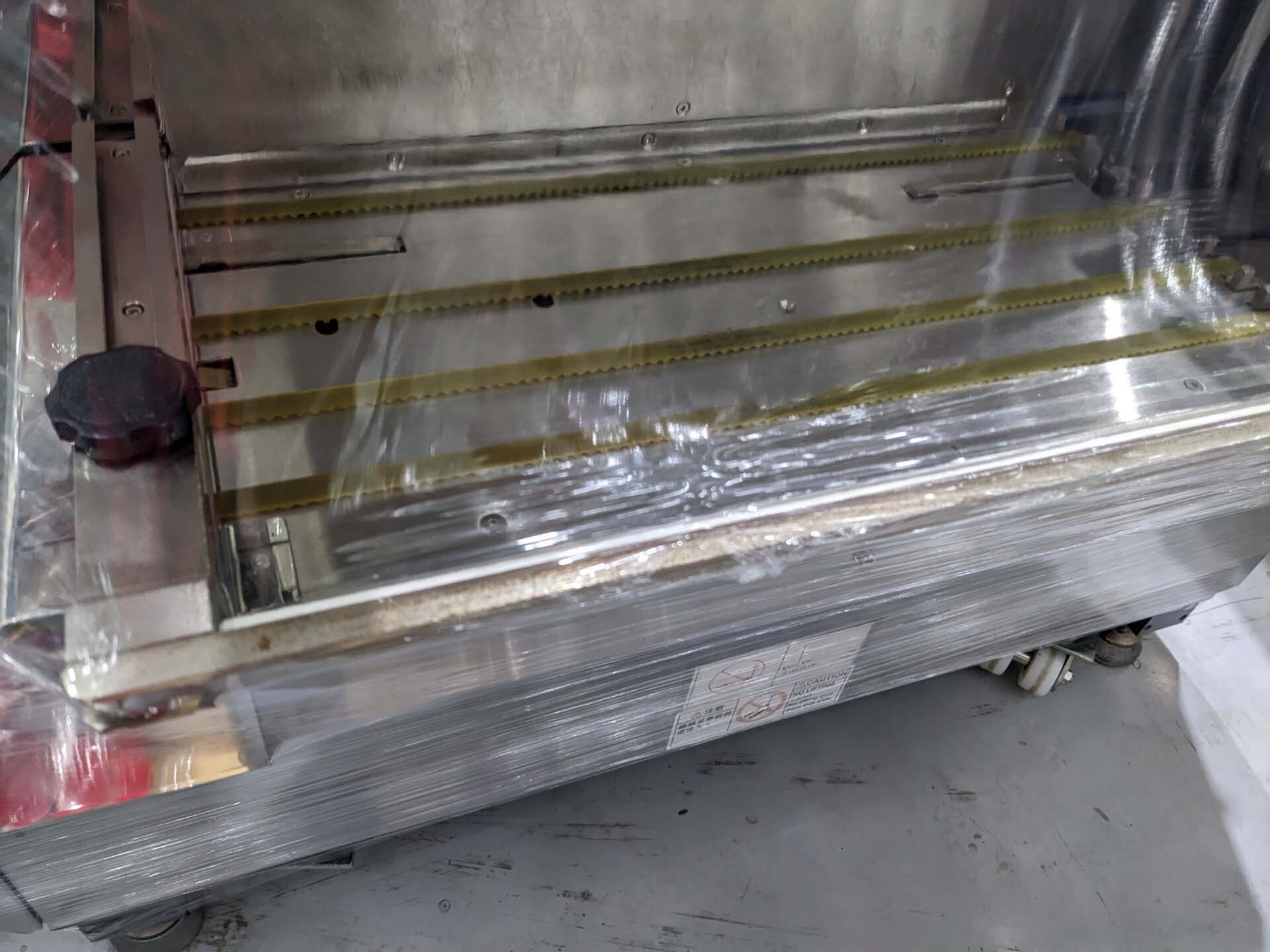

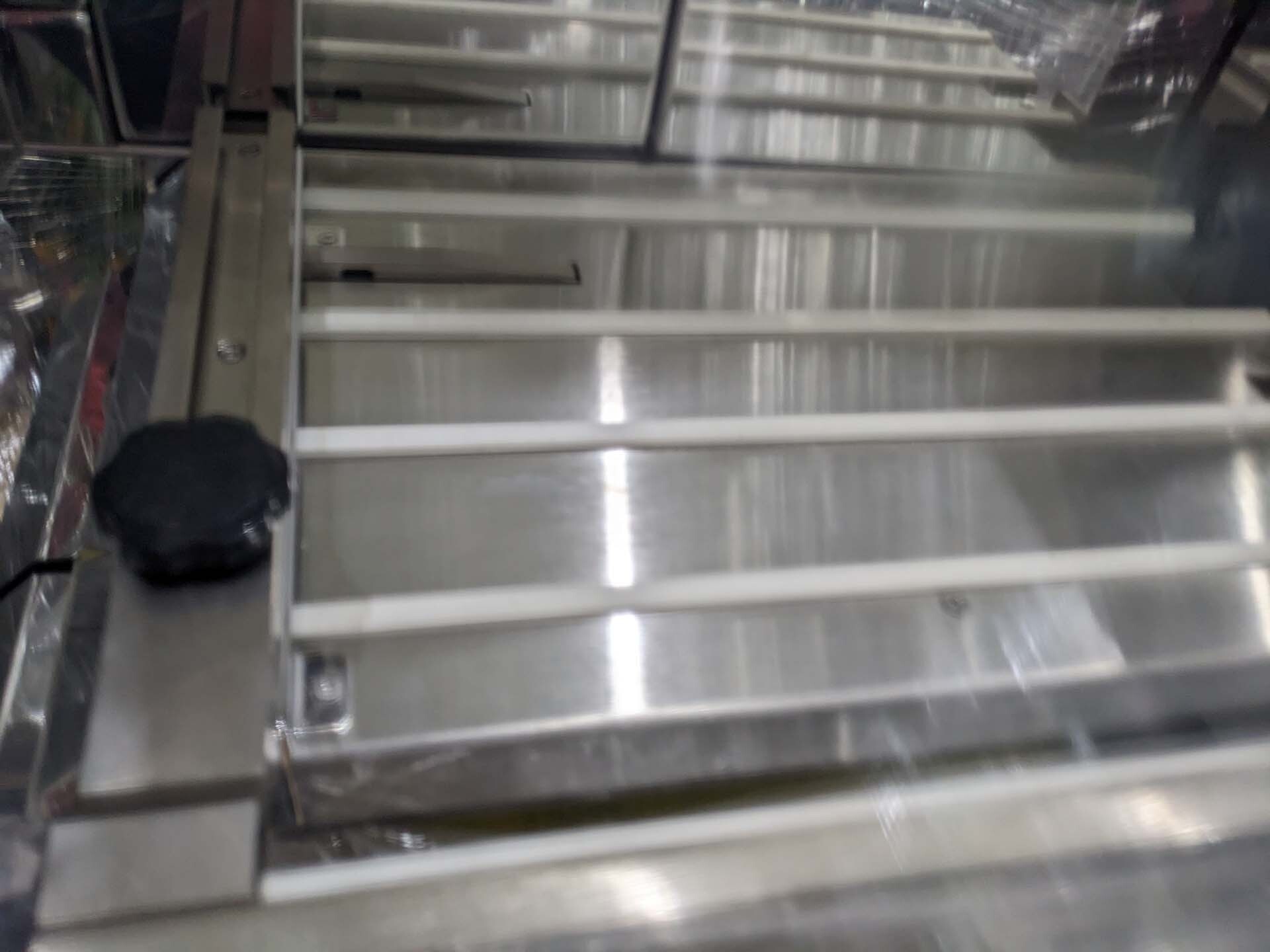

ASM ISLINDA is a bonder, a product of ASM assembly systems that is specifically designed for micro-electronics and laser machining applications. It utilizes a unique technology that combines laser micro-spot welding, electric spot and or seam welding to efficiently bond micro-components and opto-electronics. ISLINDA system is comprised of 3 essential components: the laser source, the weld head, and the power supply. The system is combined with an intelligent controller that allows manual and programmable welding operations. The weld head and laser source are all designed to provide consistent results, reducing down-time and ensuring optimal product quality. The laser source of ASM ISLINDA is equipped with a Diode or Fiber laser that produces energy in the form of light in the visible and infrared range of the spectrum. The laser beam is focused on a small spot of the work-piece that needs to be welded, creating a concentrated heat source specifically localized on that spot that will act as a melting point. The weld head is important in guiding the laser beam to the exact spot that needs welding. Depending on the type of weld being performed, a dynamic or static welding head can be used. The dynamic welding head is well-suited for applications requiring speed and accuracy, while static welding heads allows for an increased process time and with regular spacing of welded components. The power supply is responsible for delivering direct current at precise levels in order to control (evoke or exothermic) reactions for welding. It is equipped with an integrated full graphical user interface, with both manual and programmable welding processes, and wire heating capacity up to 10kA. The weld head and laser source of ISLINDA are water-cooled, which increases the life expectancy of the components and reduces consumption in terms of electricity. Overall, ASM ISLINDA is capable of handling a wide variety of micro-electronics and laser machining applications. Thanks to its unique technology, efficient and reliable bonding processes can be completed with precise accuracy. Its user-friendly advanced controller and intuitive user interface makes ISLINDA a valuable tool for any product development or manufacturing facility.

There are no reviews yet