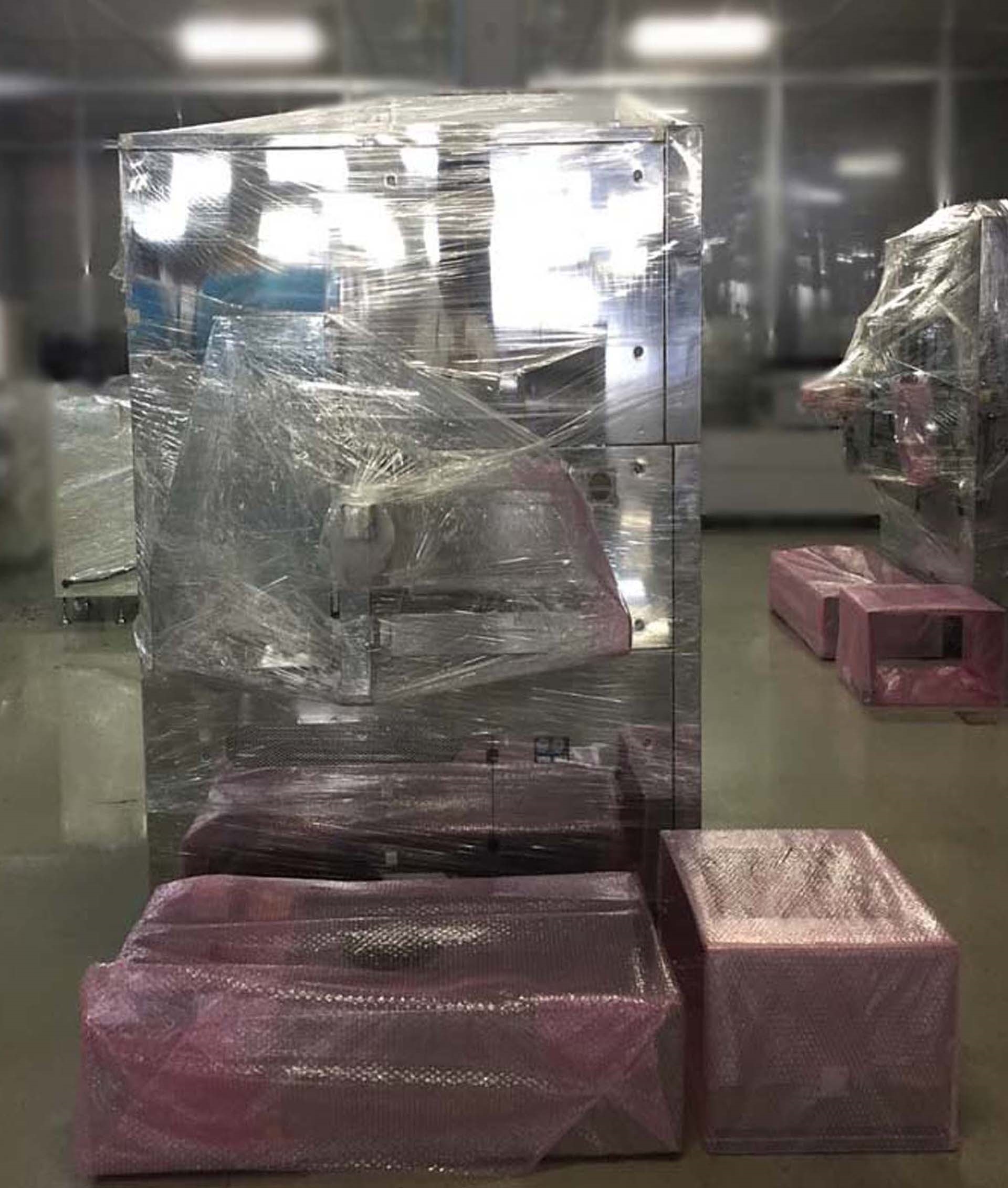

Used ASM ISLINDA #9229670 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ASM ISLINDA is a fully automated bonder for use in semiconductor and electronics packaging. It is ideal for performing wire bonding, die attaching, and chip encapsulation processes. ISLINDA is equipped with advanced monitoring and control capabilities. It has a user-friendly touchscreen GUI with a high level of process control. Its vision systems enable precise tasks such as die alignment and bond positioning. The equipment can also detect wire positioning and wire bond types. Furthermore, it includes functions to diagnose wire bonding issues and monitor process progress. ASM ISLINDA is designed to be highly scalable and it has the ability to easily switch between processing phases of different types and sizes, enabling its users to work on small and large components. This scalability of ISLINDA allows for increased accuracy and production efficiency. Furthermore, its robot driven technology eliminates the need for manual wiring, resulting in a clean and reliable environment for modern electronics assembly. The system drives thermocompression and thermal compression bonding. It has servo-controlled alignment stations to precisely position the die and wire before bond formation. Additionally, it fits a variety of thermocompression tools for different wire bonding needs. Its high-speed bonding capabilities enable higher throughput from batch to batch. ASM ISLINDA also includes advanced monitoring and safety systems to protect its users. It has a patented temperature-monitoring unit for heating tools, and an EM/RF compatibility machine to measure the emissions levels from the equipment. This ensures safety of personnel and electronic components. In conclusion, ISLINDA is a powerful automated tool for semiconductor and electronics packaging. It is highly scalable and offers advanced monitoring and safety features. It fits a variety of bonding methods and can handle any size of component. Furthermore, its high-speed bonder capabilities makes it ideal for working on modern electronics assembly.

There are no reviews yet