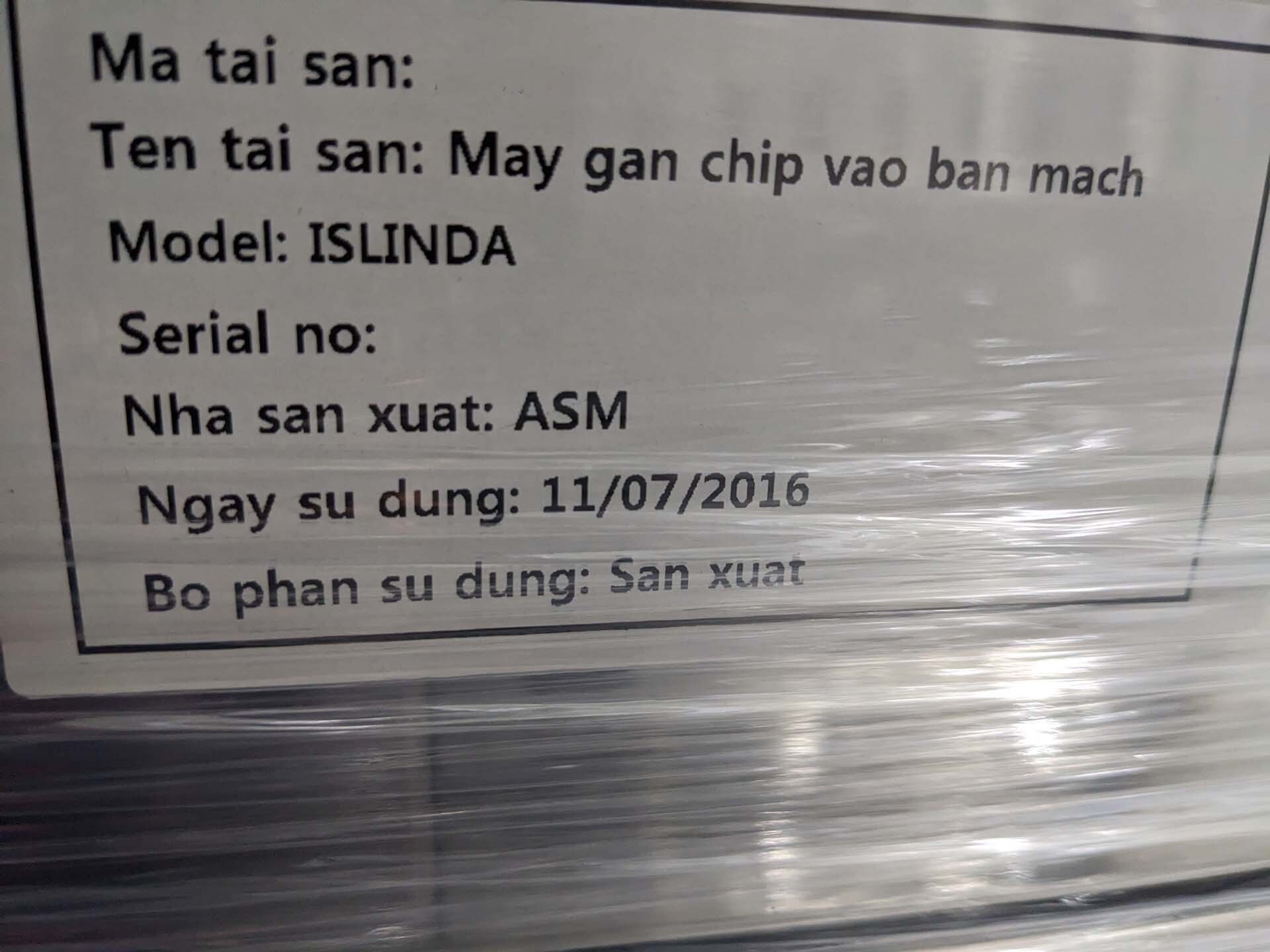

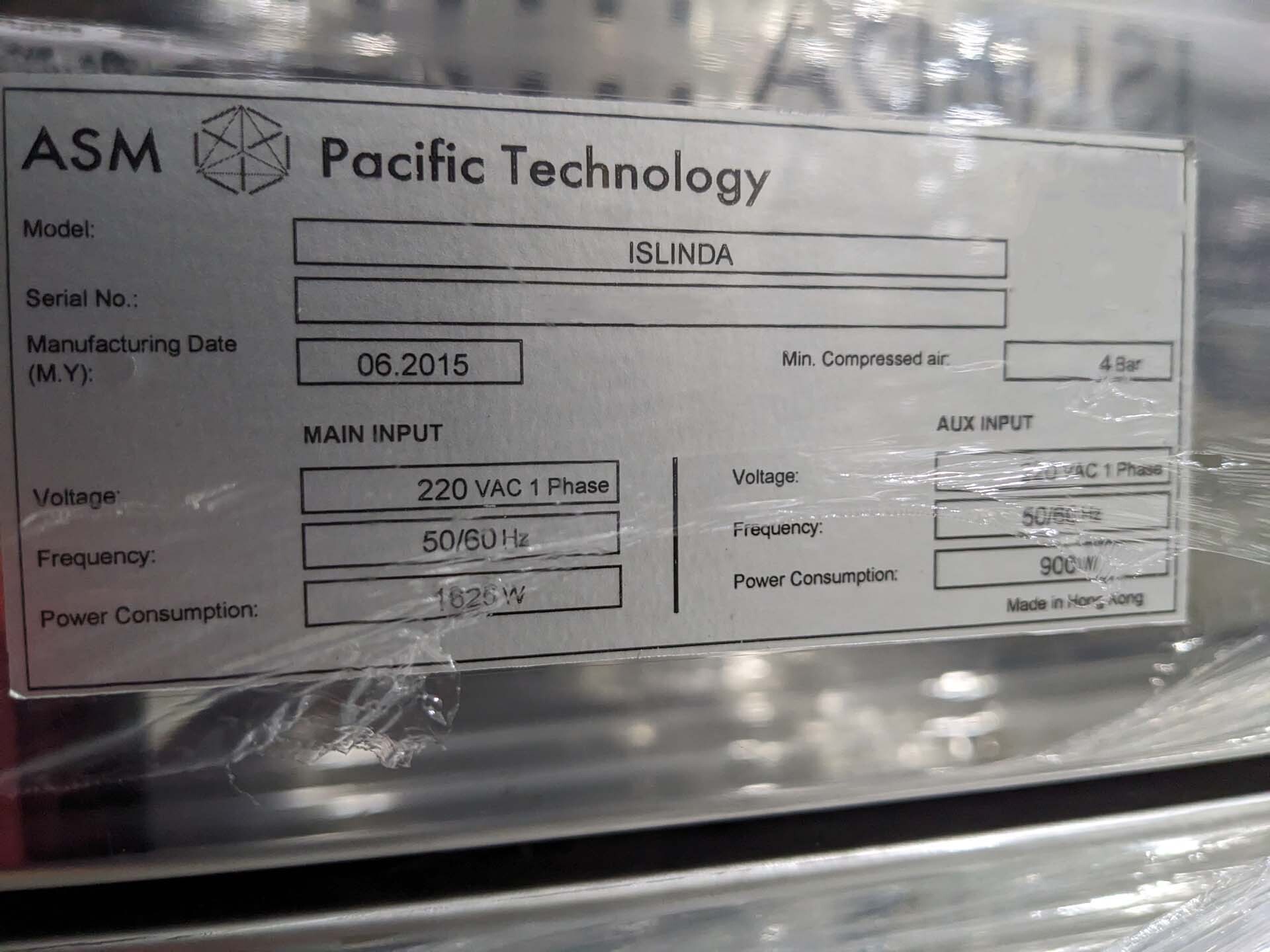

Used ASM ISLINDA #9401390 for sale

URL successfully copied!

Tap to zoom

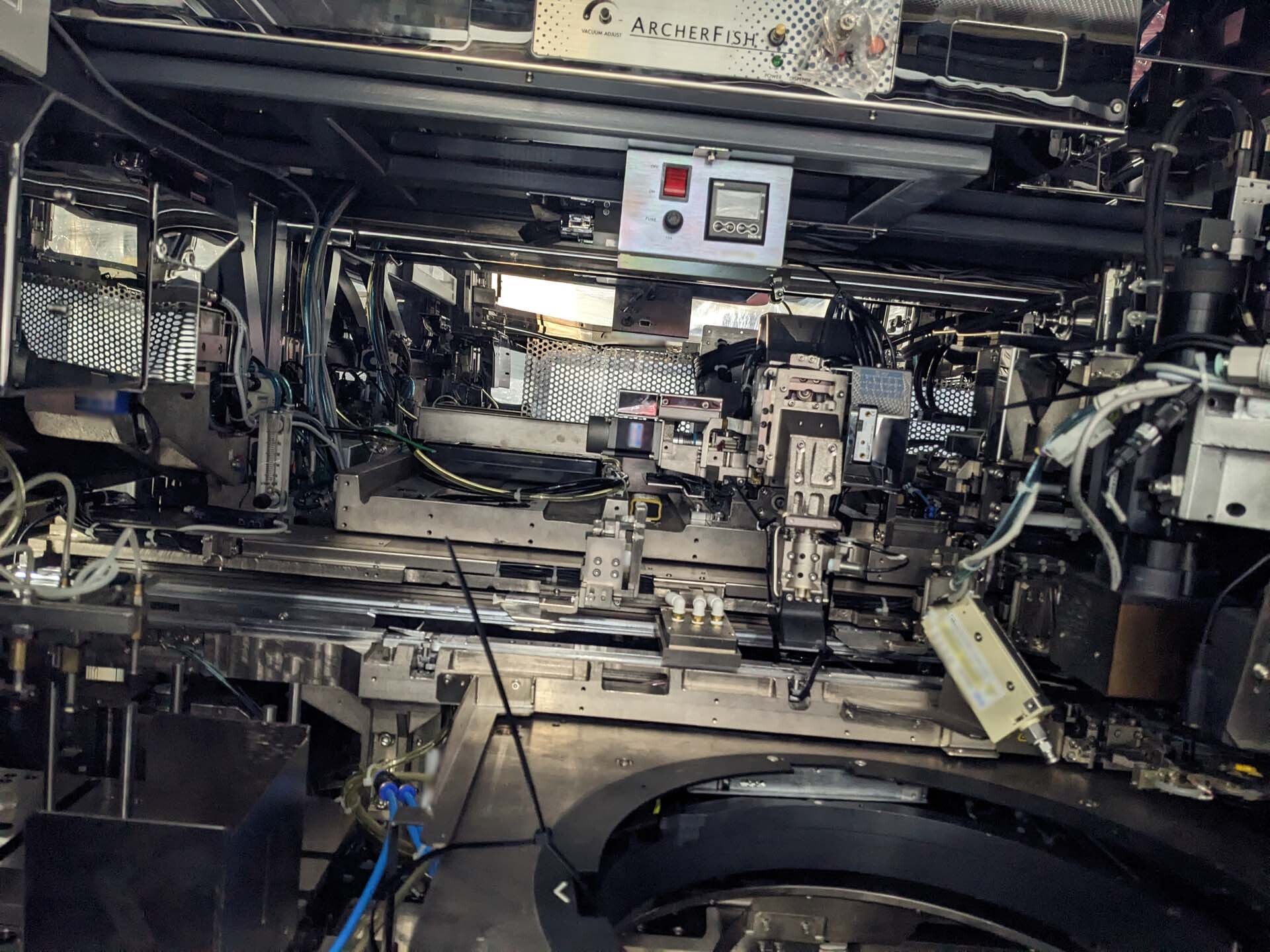

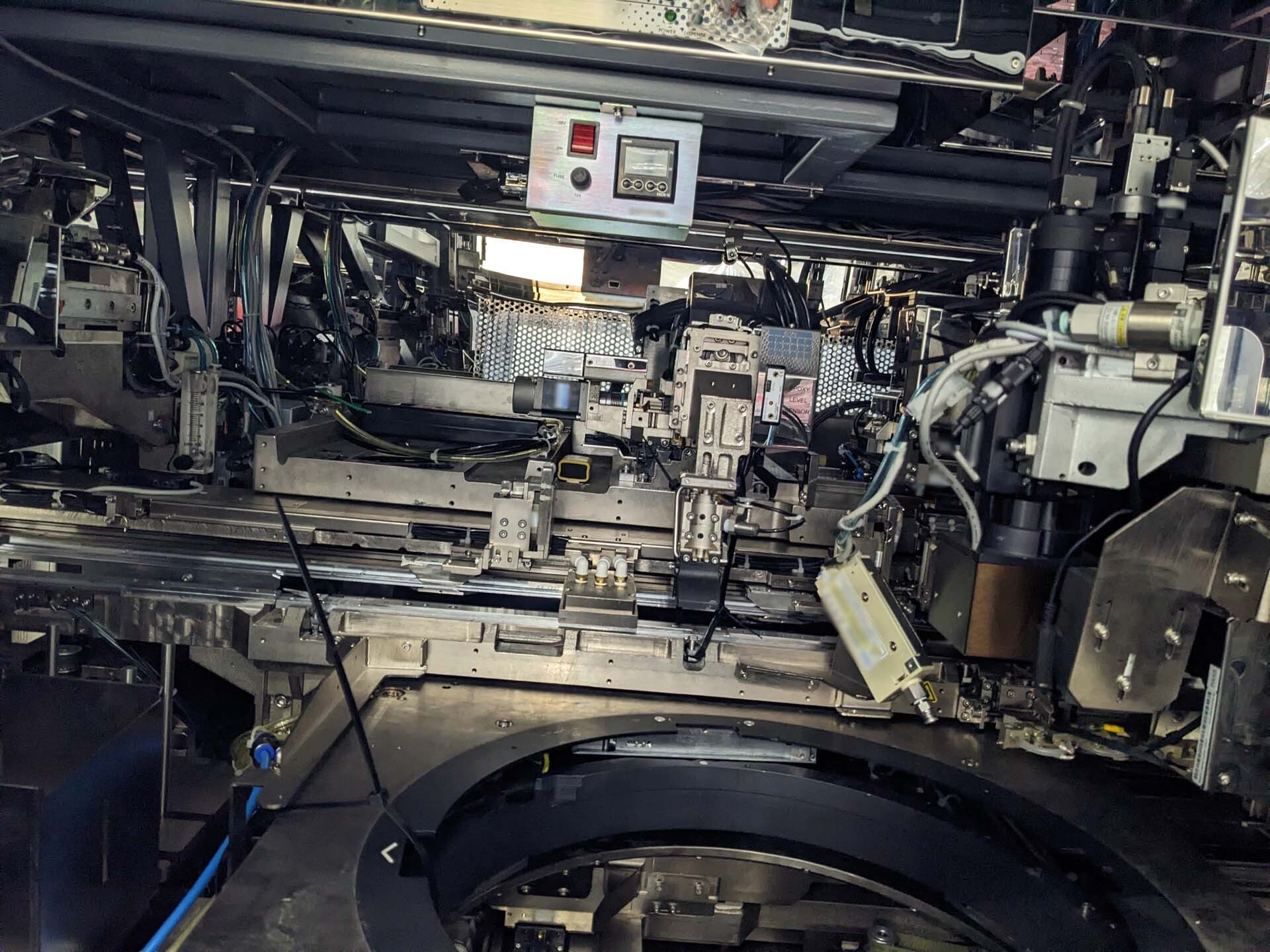

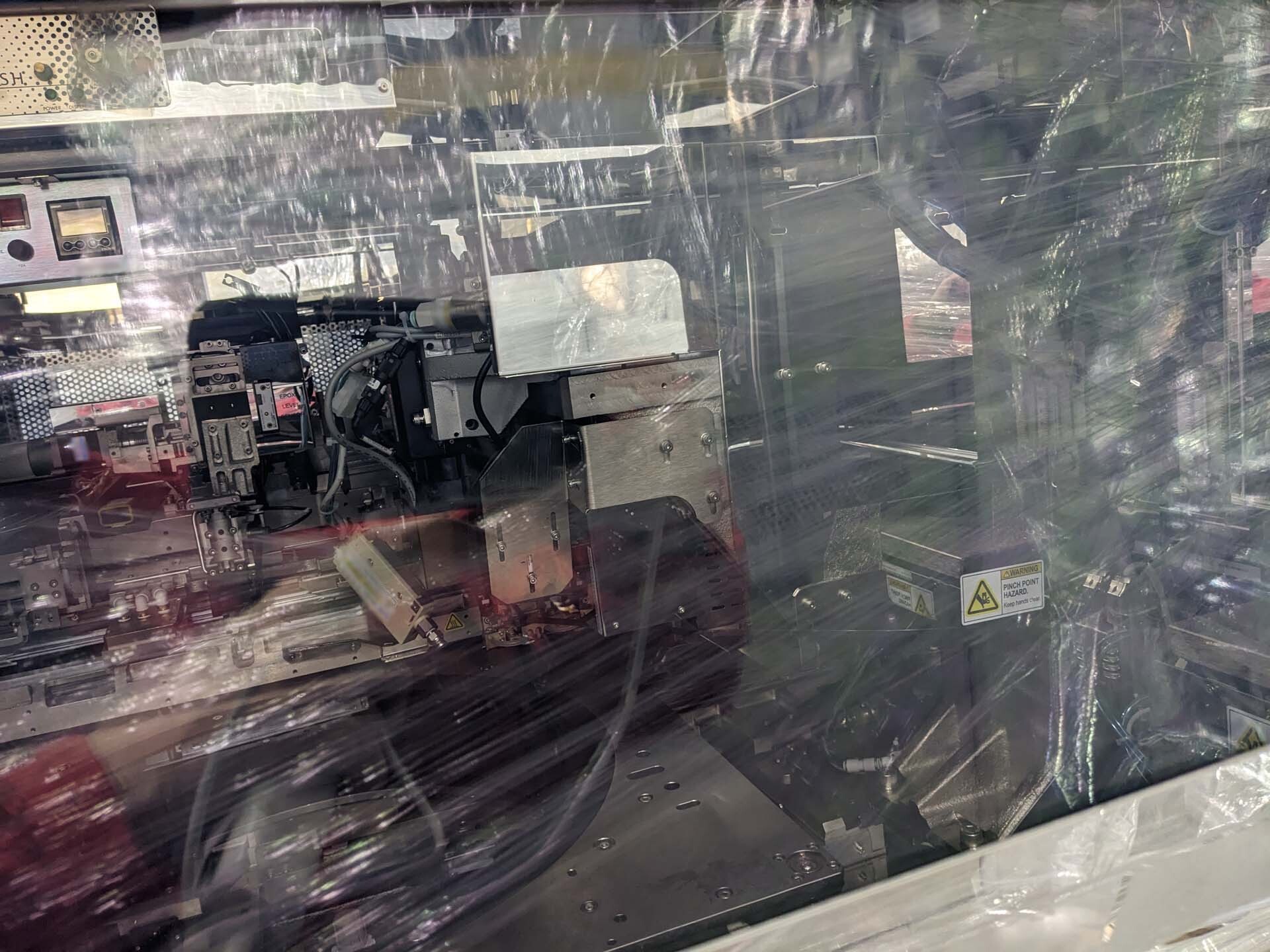

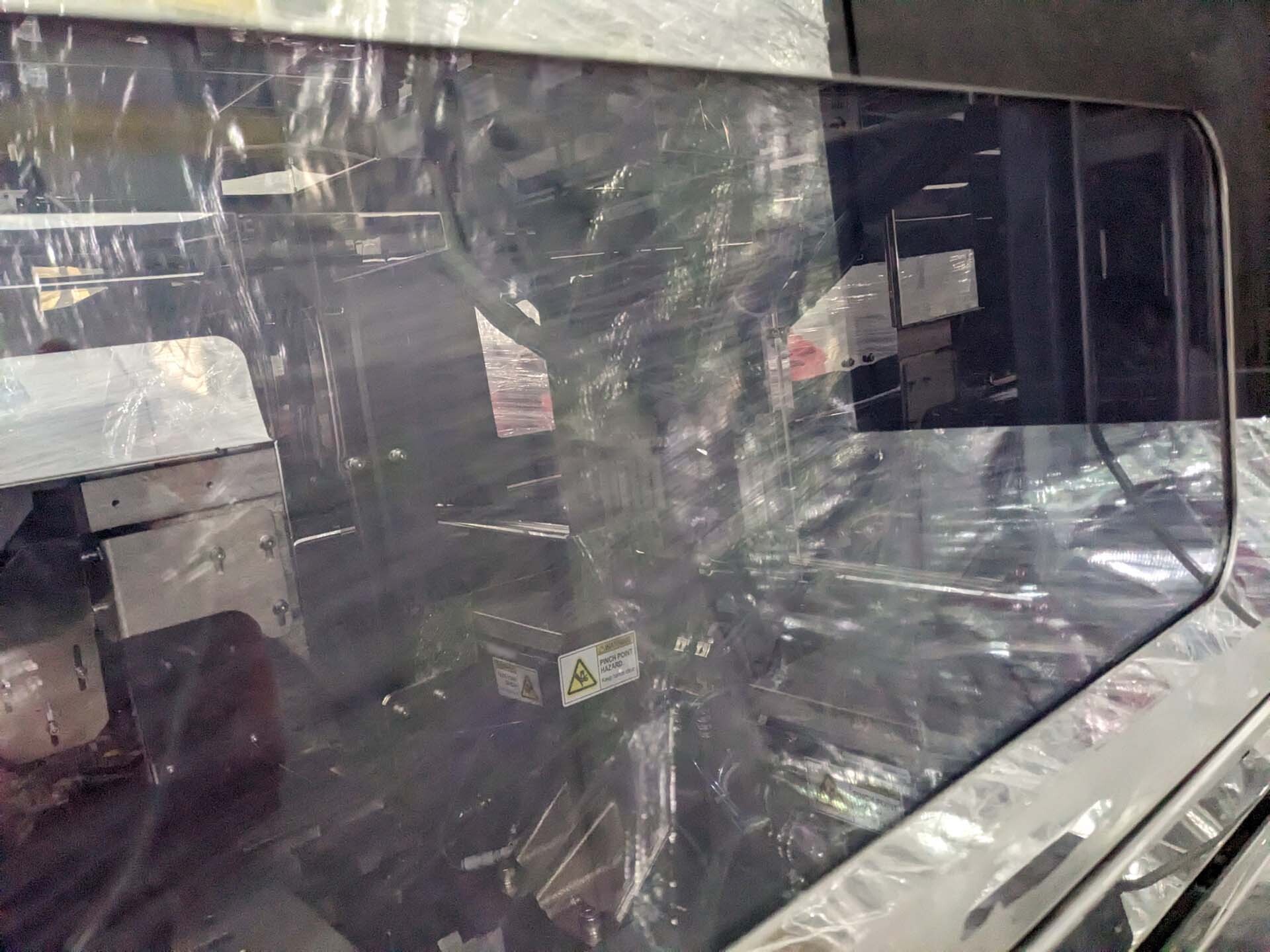

ASM ISLINDA is an automated bonding platform designed for the minimum size, highest throughput and reliable mass production of 3D containers, modules and boards. It provides superior speed, accuracy and repeatability for placement and bonding of components for 3D containers, modules and boards. ISLINDA combines screw connection and non-contact ultrasonic welding techniques to automate bonding with minimal operator intervention. The equipment comprises a compact module designed for precision placement of components within the complex space of a 3D module. The bonding technology utilises high-frequency ultrasonic energy and screw force to weld or assembly components with less heat, creating a perfect bond. This eliminates the need for additional process steps such as soldering. Components to be bonded are placed in a fixture on ASM ISLINDA's automatic carriage and the system wirelessly transfers data to the programmable controller. The controller enables two axes of motion, allowing the carriage to completely scan the 3D module and pick up components placed in it. Following this, the positioning head precisely aligns components, while the screw attachment technology applies the precise force required to secure the bond, while simultaneously maintaining a low heat transfer to the components, thus minimising distortion. ISLINDA Compact Unit also includes a vision-inspection machine to detect correctly placed components and wires before the bonding process takes place. This saves time in production and avoids unnecessary waste, ensuring only components that have been correctly positioned are bonded. The vision tool provides high-resolution video analysis, allowing the asset to perform a precise 3D visual datum mapping, using calibration data provided by the operator. Overall, ASM ISLINDA automated bonding platform provides a fast, reliable and high-quality solution for 3D container and module production. It significantly increases production throughput and accuracy and has a low downtime, with minimal operator intervention. This makes it one of the most cost-effective and reliable options for bonding and assembly requirements.

There are no reviews yet