Used DAGE 2400 PC #58694 for sale

URL successfully copied!

Tap to zoom

ID: 58694

Shear / Pull Tester

Power Requirements: 110-120 VAC @ 5 A, 220-240 VAC @ 3.15 A

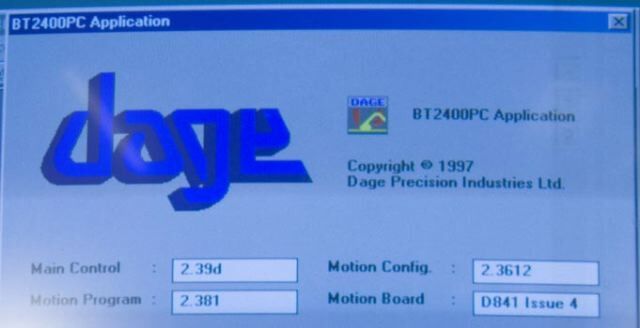

Dage BT2400PC Application 1997

Windows 98

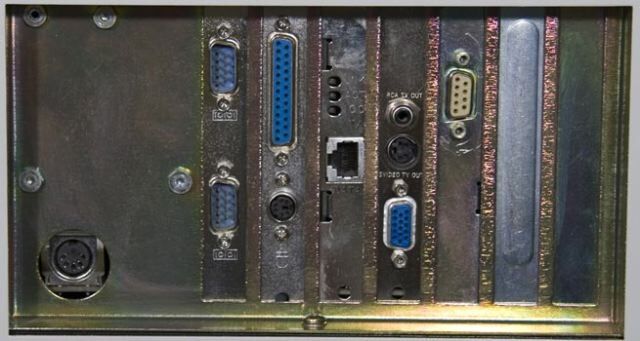

Fully configured tower style machine control computer

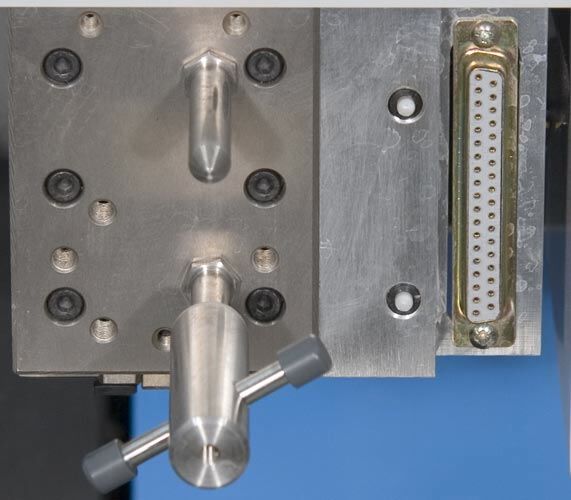

Supplied with a manually adjustable X-axis table.

This unit is a multi-function, semi-automatic test facility, offering extremely versatile destructive and non-destructive testing (NDT) or ball-bonds, and wire pull

Features:

Pentium motherboard installed versus standard EPROM board configuration

Windows 95 software interfaced to system hardware by motion control card

PC Monitor used versus typical LED-type display

Automatic Calibration and Linearity Checks

Advanced Load Cartridge Design

Mouse-driven operation for machine set-up, control and analysis operations

Floppy and hard drives include for introduction and storage of test configurations and results

Comprehensive range of analysis screens and test result files allow data analysis directly on the PC2400T. Information can be printed using standard Windows print options.

Results are automatically stored on the hard disk in CSV text file format and can be exported to floppy disk, RS232 port or directly to a factory mainframe via a network.

Quick release design ensures that change-over time between test functions is minimized

Applications include:

Ball shear

Aluminum wedge shear

Low force die shear

The system caters for these types of bond test using up to 5 kg force

Die shear using up to 100 kg force

Wire-pull testing using up to 10 kg force

Software/Configuration Versions:

Main Control: 2.39d

Motion Config: 2.3612

Motion Program: 2.381

Motion Board: D841 Issue 4

Cartridge included (Choice of one):

Model Number: 2400PC-BS5KG Ball Shear Cartridge for 5k grams

Model Number: 2400PC-WP100 Wire-Pull Cartridge for 100 grams

Specifications:

Z Axis Travel: 2.87"

Work Holder:

X Axis Travel: 1.0" manual adjustment, 0.9" motorized adjustment

Y Axis Travel: 0.9"

Maximum Test Force:

Z Axis: 10 kg

Y Axis: 100 kg

Minimum Detectable Load (From Software Version 2.20):

5% of currently selected test load range

(For destructive testing - 5% of the threshold parameter slider setting)

Work Area (Swing Round Tool): 8.5" minimum

Keypad: 4 x 4 matrix

Joystick: Self centering

Illumination: 20W Halogen lamp

Vacuum Base: 20" Hg minimum (supply to machine)

Sound Level:

Continuous A-weighted sound pressure at the workstation < 70 dB(A)

Die Shear Testing Specifications:

Measurement Accuracy: +/-0.5% of load cell rating

Test Mode: Destructive or Non-Destructive

Shear Mode: Automatic

Shear Direction: Y axis, front to back

Shear Tool (Standard): Tungsten carbide

Landing Speed (Programmable): 0 to 0.039" / s

Landing Force: 3g to 10g (depending on landing speed)

Shear Height:

Range: 0 to 0.019"

Resolution: 0.00025 mm

Accuracy (At Start of Test): +/-0.00025 mm

Accuracy (Though Test): +/-0.0005 mm

Shear Speed (Programmable Range): Cartridge dependent

Y Axis Travel During Shear Test: Cartridge dependent

Ball Shear Testing Specifications:

Measurement Accuracy: ±0.5% of load cell rating

Test Mode: Destructive or Non-Destructive

Shear Mode: Automatic

Shear Direction: Y axis, front to back

Shear Tool (Standard): Tungsten carbide

Landing Speed (Programmable): 0 to 0.039" / s

Landing Force: 3g to 10g (depending on landing speed)

Shear Height:

Range: 0 to 0.5 mm (0.019")

Resolution: 0.001 mm

Accuracy (At Start of Test): ±0.00025 mm

Accuracy (Through Test): ±0.0005 mm

Shear Speed (Programmable Range): Cartridge dependent

Y Axis Travel During Shear Test: Cartridge dependent

Pull Testing Specifications:

Measurement Accuracy: ±0.5% of load cell rating

Test Mode: Destructive or Non-Destructive

Pull Mode: Manual, Step back, or Autohook

Pull Direction: Z axis, vertical

Z Axis Stroke: 73 mm

Pull Tool (Standard): Hook or tweezer

Pull Speed (Programmable):

Range (up to 1kg rating): up to 5.0 mm/s

NDT Overshoot: 0.5% FSD.

DAGE 2400 PC is a precision ball and wedge bonder used widely in the semiconductor industry. It is capable of performing fine pitch and wire wedge bonding, as well as precise thermocompression welding. The equipment is capable of producing a wide range of bond sizes, with a maximum wire size of 0.0025 inches (25 μm). It is compatible with both copper and gold bond wires, allowing for the use of either material. The system's electronic settings can be adjusted easily, allowing the user to customize parameters such as bond time and current settings. DAGE 2400PC is also equipped with an Anti-Tilt Unit to reduce the chance of wire distortion during the bonding process. The machine is designed for use with a wide range of substrates. It is equipped with contact position sensors to ensure optimal alignment of components during the wire bond process. To further improve accuracy, the tool is equipped with a CCD camera, which can be used to precisely measure the bond and inspect it for reliability and quality. For operators, 2400 PC functions mainly through touch screen display. This allows the user to easily access a variety of options, including adjusting program settings, viewing bonding parameters and information regarding components, and operating the bonder. 2400PC also includes an alarm asset that can alert the user if a bonding error has occurred. This allows corrective action to be taken to prevent any further disruption to the operation. Also included is an auto-chuck model, which automates the process of picking up, positioning and ejecting components. This reduces cycle time and improves the overall output of the bonder. DAGE 2400 PC is a reliable, versatile and precise bonder. It can be used for a wide variety of tasks and is capable of producing reliable and consistent results. Its ease of use and ability to customize settings make it a great choice for semiconductor production.

There are no reviews yet