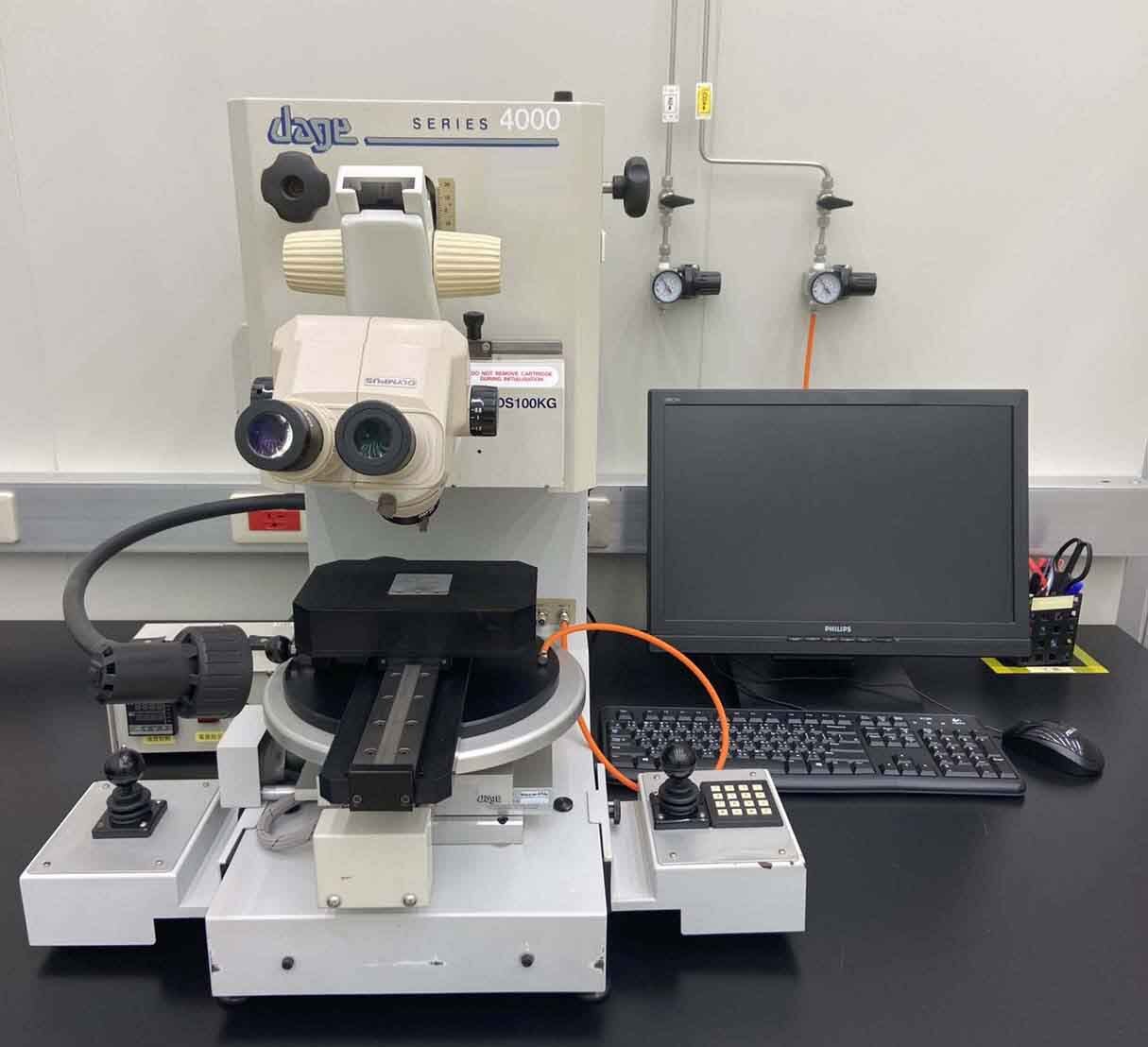

Used DAGE 4000 PXY #9375691 for sale

URL successfully copied!

Tap to zoom

DAGE 4000 PXY is an advanced bonder featuring precision wire loop presses and the latest in bonding technology. It is capable of producing high-performance die-attach and other delicate bonding activities with both speed and accuracy. DAGE 4000PXY can bond materials such as leadframe, ceramic and plastic, without compromising the integrity of the bond or material due to its state-of-the-art wire looping equipment. This makes it ideal for a variety of applications in the bonded assemblies and precision circuit assembly. The wire loop presses feature an enhanced operator interface that allows the operators to have complete control over the bonding loop shape, pressure, loop size and height, and wire tension. The integrated PID control loop ensures accuracy and repeatability of the wire loop press. The press also features large force capabilities to adapt to a wide range of products, allowing it to effectively manage a variety of bonding challenges. 4000 PXY also includes a fully automated vision categorization and component recognition system, allowing it to quickly identify and select components. This technology allows the device to quickly and accurately recognize component types and sizes, allowing it to quickly and precisely attach the component to the circuit board. In addition, the vision unit is integrated into the controls, allowing the device to automatically adjust standard behaviors to be more specific and precise to each job. 4000PXY is also fitted with a variety of cooling systems, allowing it to effectively manage its Bondhead's temperature, ensuring the most optimized operational conditions for its activities. This cooling machine also ensures that the bondhead temperature is maintained within predetermined limits, protecting the product being bonded from thermal overload. DAGE 4000 PXY is a highly dependable and precise bonder, perfect for a variety of circuiting and component-attachment tasks. Its integrated vision categorization and cooling systems allow it to accurately bond components and to ensure product integrity. This makes it a great choice for bonders in the precision circuit assembly and die-attach bonding fields.

There are no reviews yet