Used DAGE 4000 #9409425 for sale

URL successfully copied!

Tap to zoom

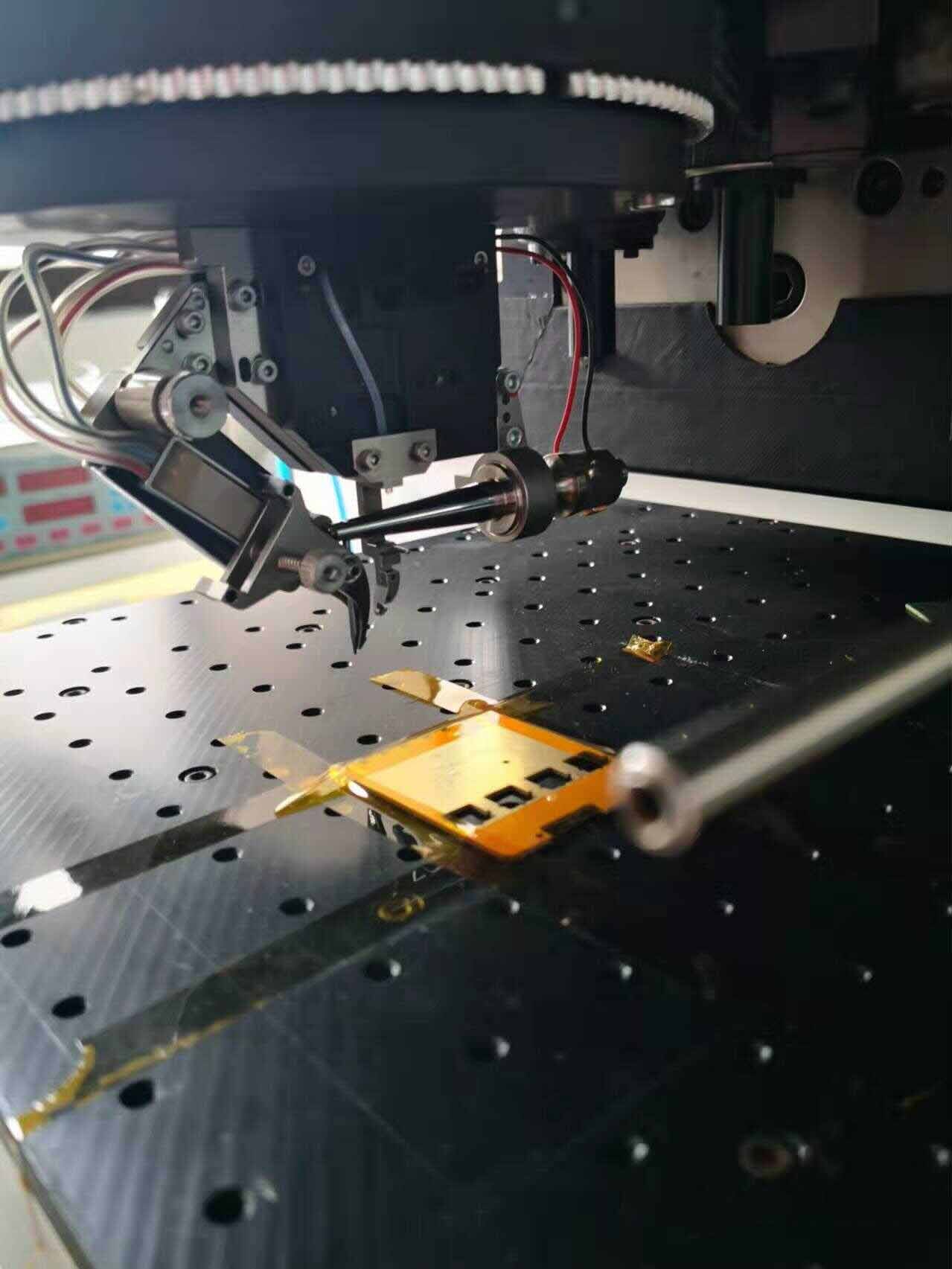

DAGE 4000 is a high quality, versatile second generation die bonding tool for the assembly of devices such as sensors, capacitors and thin-film hybrids. It has a rugged manual alignment equipment that measures just 9" x 17.7" and is capable of working with components up to 12 x 12 mm and an accuracy of ±2.5 μm. It can also perform eutectic dieattach, epoxy dieattach, soldering and Wave Solder processes. The operator can achieve accuracy of ± 2.5 μm XY alignment and ± 0.5° angular alignment. In addition, the return system which provides "lift and reclamp" at the end of every join cycle allows for subsequent die-bonding and soldering operations. The unit is capable of working with a variety of materials, including gold, silver, copper, aluminium, and alloys such as W305 and HT, as well as IC die in a range of package formats. For more advanced applications, 4000 is available with optional extras such as a range of wafer chucks, manual and automatic image recognition, vision for inspection and alignment, and rotary axes for improved access and flexibility. The machine's modular construction allows for easy expansion and can also function in combination with third party equipment. It requires a temperature controlled environment and a 3-phase power input of 230V, 50/60Hz and 4KW to operate. DAGE 4000 has a mechanical resolution of 0.1 micron, while the die bonding head has a radial speed range of 0.007 - 200mm/s. The machine can be purchased with up to four simultaneous bonding heads to enable multiple die-bond cycles to be performed at once, which further increases speed, throughput and productivity. The tool provides an intuitive, easy-to-use interface, allowing all users to work in a safe and effective manner. In addition, a range of accessories including cameras and software tools are also available. Overall, 4000 is a powerful, versatile, accurate and easy-to-use die bonding tool that has been designed to meet the needs of both the semiconductor and device production market for those seeking large volume, high efficiency, repeatability and accuracy.

There are no reviews yet