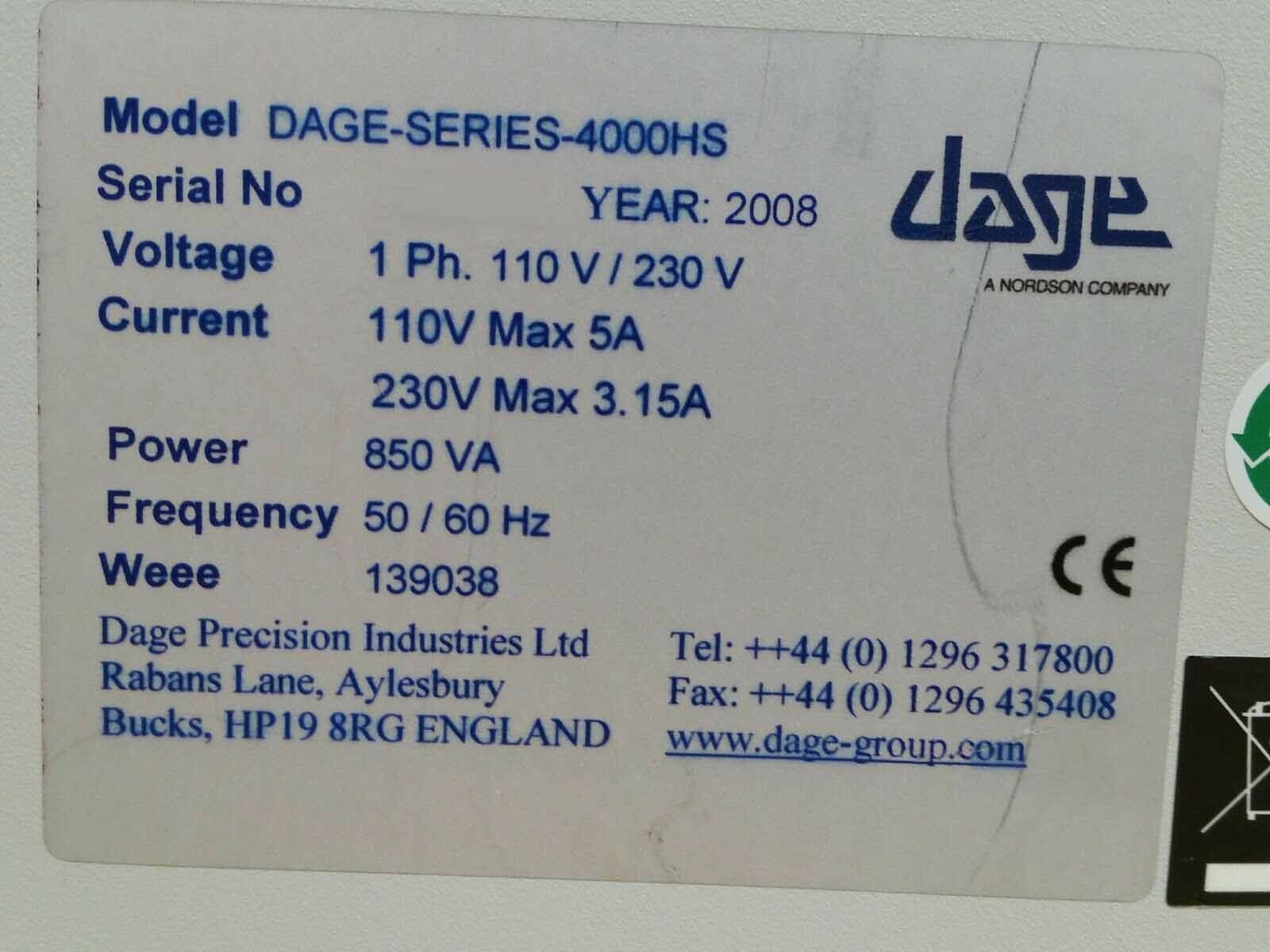

Used DAGE 4000HS #9291950 for sale

URL successfully copied!

Tap to zoom

ID: 9291950

Vintage: 2008

Wire bond tester, parts system

With LEICA GZ6

VGA / SVGA LCD Flat panel display, 17"

Vacuum supply

Hg Plastic pipe: 500 mm

Pneumatic supply: 4 bar, 6 mm

Dry air pipe

X, Y Axis accuracy: ±10 microns over 50 mm

X, Y Axis repeatability: ±5 microns over 50 mm

X, Y Axis resolution: <1 micron

X, Y Axis maximum speed: 2 mm/second

Y Axis maximum force: 100 kg

X Axis maximum force: 5 kg

Z Axis travel: 65 mm

Z Axis accuracy over full travel: ±10 micron

Z Axis accuracy over 2 mm: ±2 micron

Z Axis resolution: ±0.125 micron

Z Axis maximum speed: 7 mm/second

Z Axis maximum test speed: 5 mm/second

Z Axis maximum force: 10 kg pull at 5 mm/second

Workholder working envelope:

X: 220 mm

Y: 220 mm

Z: 50 mm

Missing parts

Power supply: 100/110 V, 220/240 VAC, 50/60 Hz, Single phase

2008 vintage.

DAGE 4000HS is a state-of-the-art advanced ball bonder equipment designed for high-volume production. The system features a high-performance, high-speed bonding head and motor-controlled tilt press that offers maximum flexibility to meet a wide array of customer requirements. With the ability to support up to four independent bonding heads, this unit is custom-engineered for superior multi-bond performance and greater throughput. The superior bonding features include high-precision composite motion control, advanced wire pull technologies, and a more powerful head design. DAGE 4000 HS is the ideal solution for manufacturing high-precision, complex devices with the highest capacity and speed. The advanced dual-pump tilt press of 4000HS allows operators to achieve the exact bond pull force and desired bond angle for best wire pull results. The advanced motion control machine of the tilt press offers the highest accuracy and most stable control throughout the full tilt range. Along with the high-speed bonding head, this tilt press enables the tool to bond a wide variety of wire sizes including 0.025 - 0.030 inch (0.63 - 0.76 mm). The superior bond pull speeds available on this asset ensure that high-volume production speeds of up to 40x faster than manual bonding can be achieved. 4000 HS also includes bond gap monitoring, component and motion control compensation, and high-speed wire pre-feed and post-feed capabilities. All of these features allow the model to produce a consistent, high-quality bond to each device while reducing the potential for reject errors. Additionally, the equipment provides a comprehensive suite of diagnostics and self-test capabilities to ensure that the system is always running at peak performance. DAGE 4000HS is uniquely designed for robustness and reliability in high-volume production environments. It is constructed from durable materials and components that are designed to withstand the rigors of high-volume production. This ensures that the unit will continue running efficiently with minimal maintenance, reducing downtime and increasing productivity. The machine also offers built-in health monitoring and auto-diagnostic features to quickly identify and alleviate problems before they become costly problems. DAGE 4000 HS is the ideal choice for high-volume manufacturing of precision engineered devices. With its high flexibility, superior performance, and advanced features, it provides manufacturers with the ultimate tool to meet their production demands.

There are no reviews yet