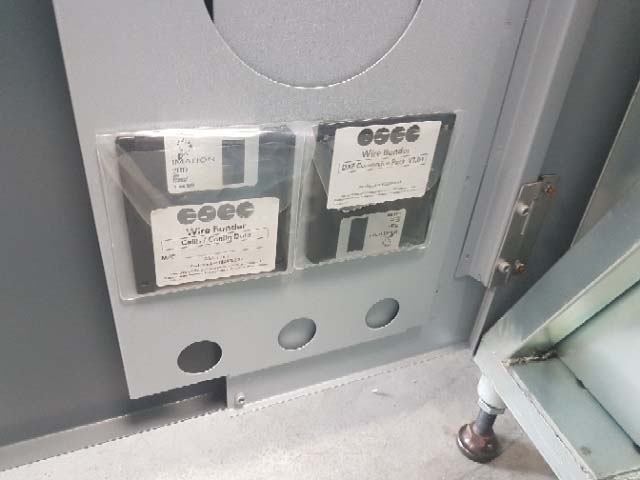

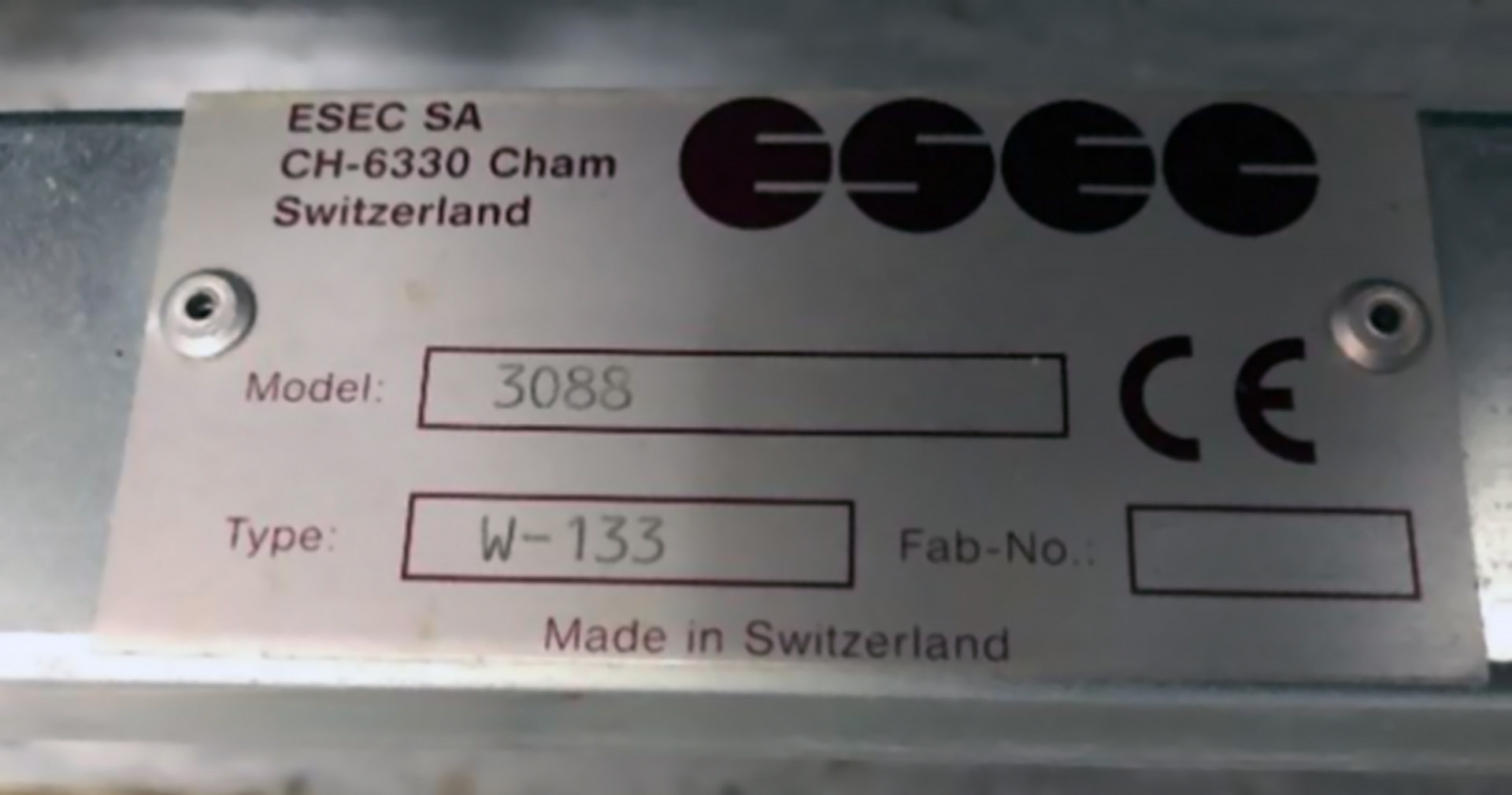

Used ESEC 3088 #9257962 for sale

URL successfully copied!

Tap to zoom

ID: 9257962

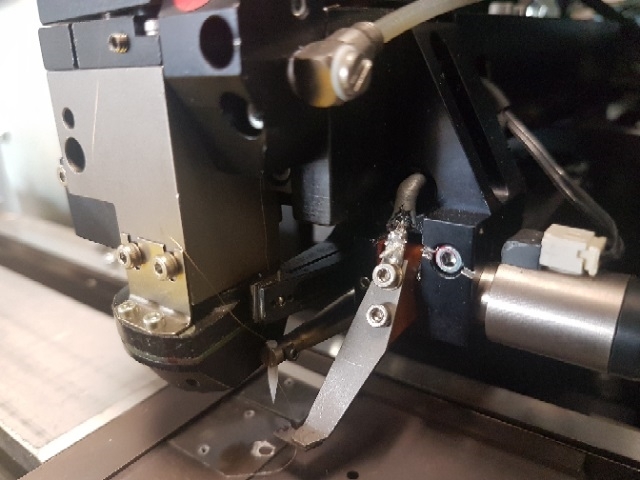

Gold ball wire bonder, parts system

Type: W-133

OLYMPUS SZ 30 Microscope.

ESEC 3088 is a range of bonders designed manufactured by GE Inspection Technologies. It is primarily used for sealing, bonding and forming complex electronic components on Printed Circuit Board (PCB) assemblies. 3088 bonders are a highly advanced, automated equipment, that offer superior convenience, control and precision, compared to traditional soldering. At the core of ESEC 3088 bonding system is its precision robotic arm which is designed to move around 360 degrees to create accurate, repeatable joints using a range of techniques. The robot arm can bond solderballs, ribbon cables, wires, and connectors to create complex assemblies. An Electron Beam (EB) welding option can be added to the robot arm for even more precise welding and brazing applications. 3088 also has a range of integrated software solutions for joint verification and production control. The machine comes with a user-friendly GUI which helps manage processes and materials, as well as supply chain tracking and traceability. ESEC 3088 bonders incorporate a vision unit to help maximize production quality. The vision machine includes lasers, cameras and fatigue-resistant lighting, that are designed to measure how joints are joining up by recognizing dry joints, bridging, force control, and polarity. The vision tool can generate alerts when incorrect joining conditions are detected, and allow operators to adjust process parameters in real-time. 3088 offers a number of additional features for process optimization. It is designed with built-in sensors that measure and monitor temperature, pressure, and current throughout the bonding process. It also has a patented medium frequency inverter which helps to minimize energy consumption. And finally, it has a highly sophisticated closed-loop control asset which ensures precise positioning of components on the assembly during bonding. In conclusion, ESEC 3088 is a high-precision, automated bonder designed for the manufacture of electronic components on printed circuit boards. It delivers superior convenience, control and precision compared to traditional soldering, and a range of features designed to help optimize processes and improve production quality.

There are no reviews yet