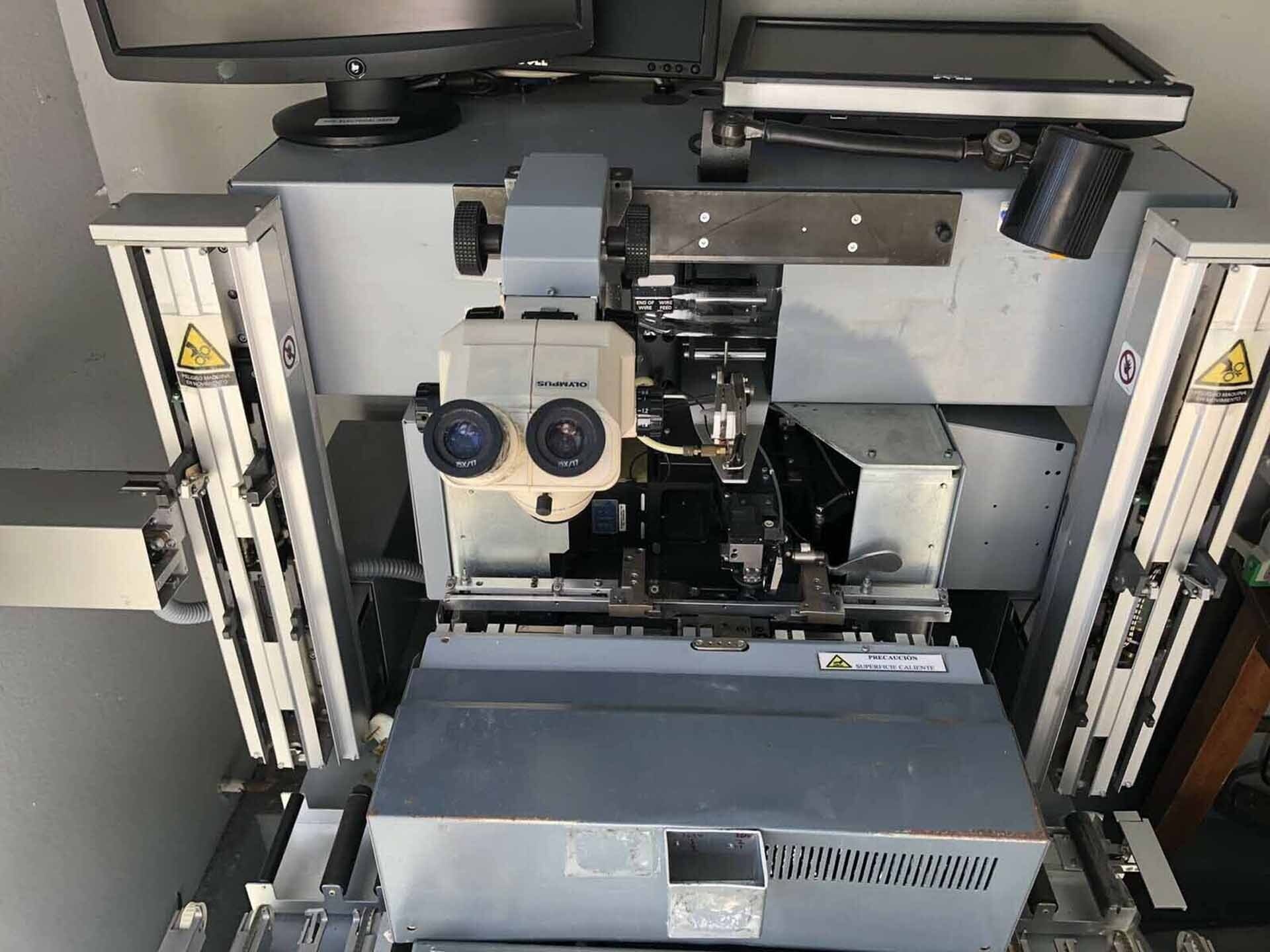

Used ESEC 3088 #9315827 for sale

URL successfully copied!

Tap to zoom

ID: 9315827

Vintage: 2000

Wire bonder

Type: W133

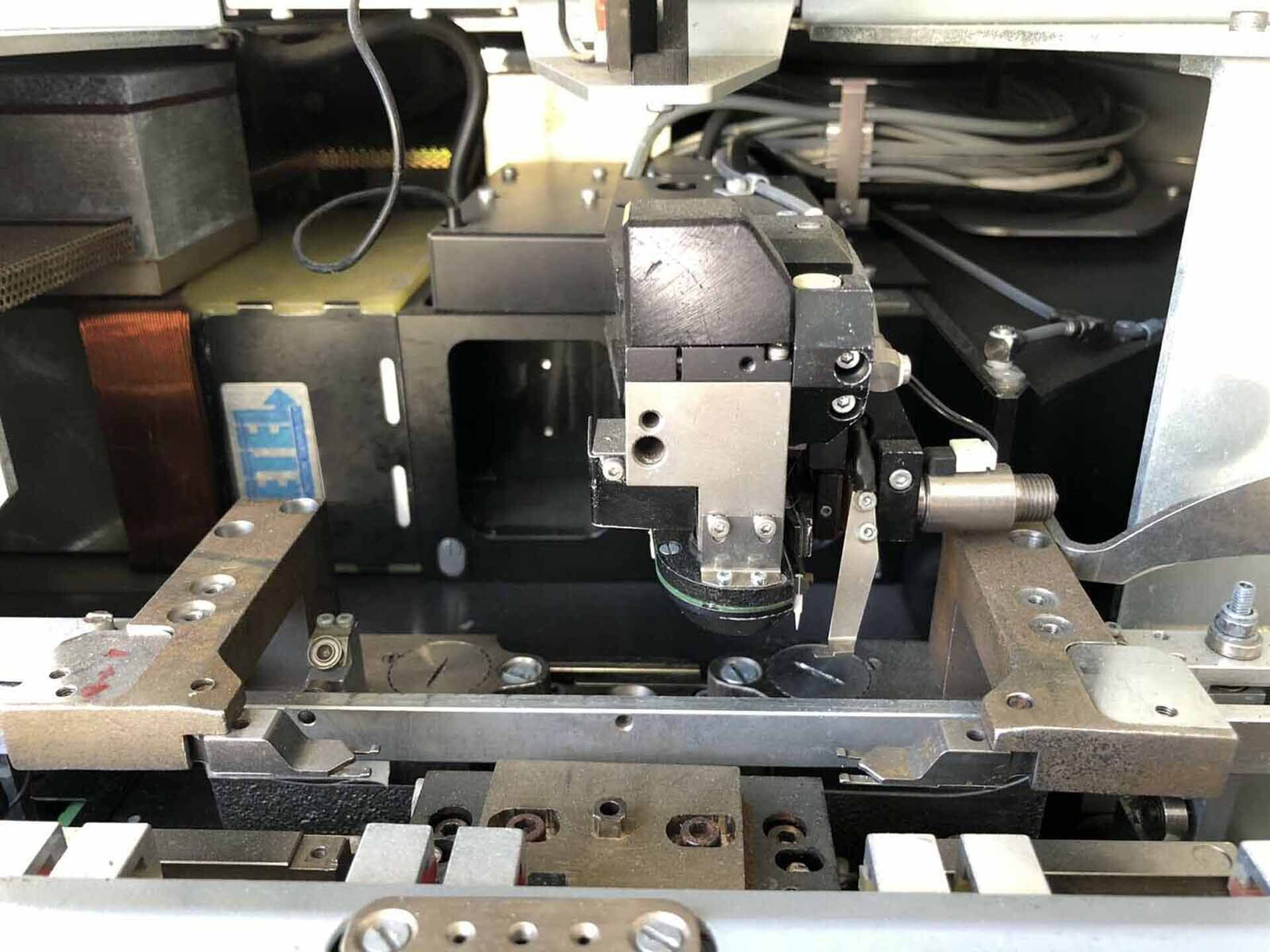

Ultrasonic frequency: 130 kHz

Cu-kit with movable electrode

Sprint UPH: (10) Wires/second

Maximum bonding area: 52 x 70 mm

Process zone temperature: Ambient to 300°C

Various looping profiles

Gold wire: 17.5 - 50 µm Diameter

Copper wire: 17.5 - 25 µm Diameter

2000 vintage.

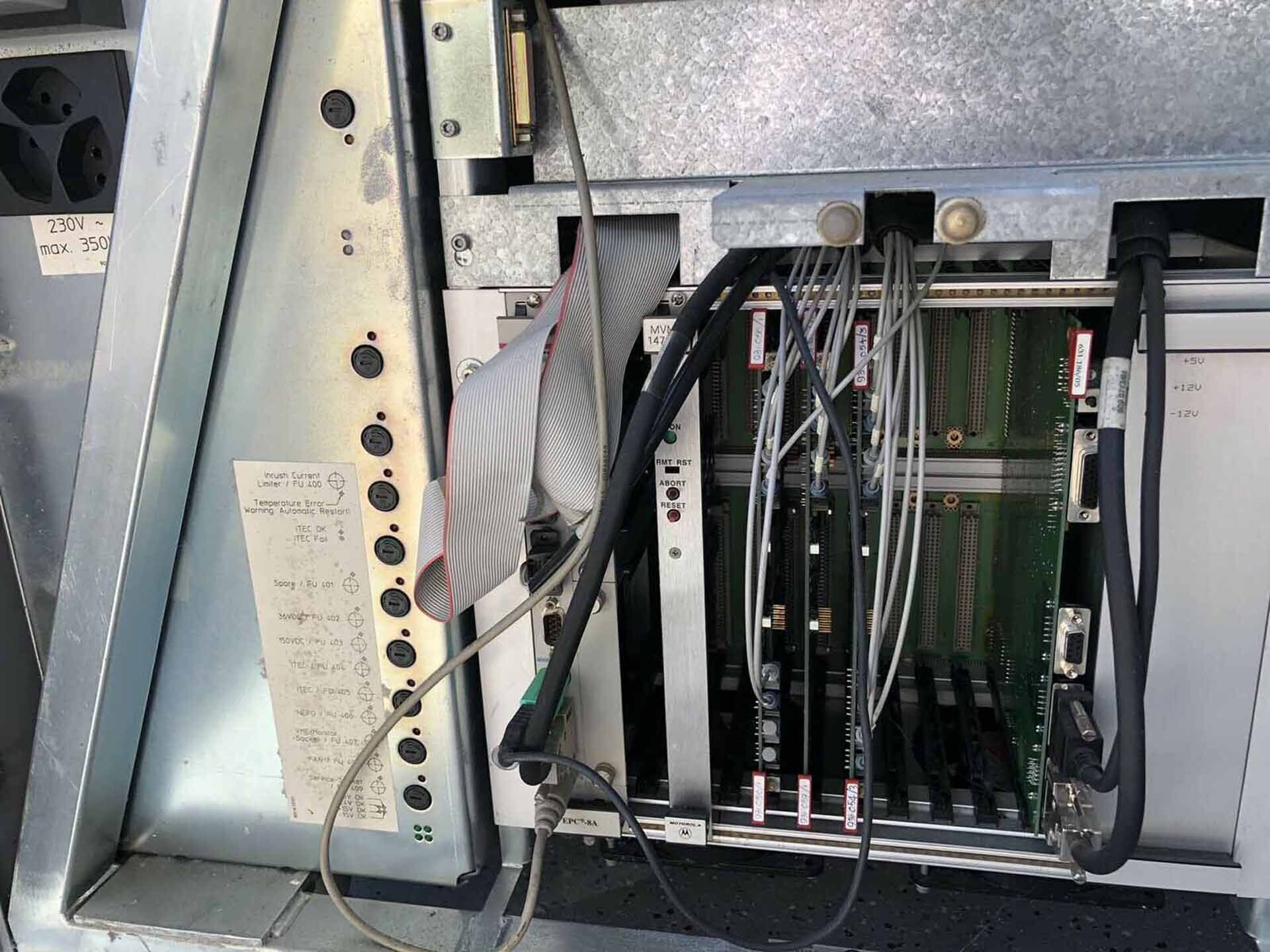

ESEC 3088 bonding machine is a versatile and reliable soldering and die bonding equipment, designed and manufactured by ESEC, Inc. This system comes with an advanced touch screen graphical user interface (GUI) that makes it simple to use and program. Its intuitive programming capabilities allow the operator to quickly get up to speed with its operations and programming abilities. 3088 consists of a three-axis stage, a laser scanning unit, and an integrated controller. The automated three-axis stage gives the operator an ergonomic platform to align the assemblies and geometry for accurate process results. The integrated laser scanning machine makes precise alignment and positioning possible within the working area for accurate positioning and process results. The three-axis stage is supported by a motor driven tool that provides for increased speed and accuracy during the process of component placement. This is also an important factor in determining the overall quality and repeatability of the process. The primary features of ESEC 3088 include an integrated process controller that allows the operator to access and reconfigure the machine, or to define and change specific solder and die bond process parameters. This process control asset is very user friendly, with a wide variety of programming and setup options available through the touch screen GUI. The machine can also be expanded with optional accessories, including vision systems, electro-chemical decapsulation systems, and resistive heating plates for use in various bonding scenarios. 3088 is capable of performing a wide variety of process tasks. It is primarily used for the bonding of small electronic components and assemblies. The flexible and accurate process parameters, integrated laser scanner, and precise three-axis stage allow the operator to easily and precisely place components into position and bond them accurately. This model also features a variety of other functions such as automatic inspection, vision inspection, and monitor recording. ESEC 3088 is designed to improve component bonding speed and accuracy and provide an overall result that is as close as possible to the design specifications.

There are no reviews yet