Used ESEC TSUNAMI W3100 #9286421 for sale

URL successfully copied!

Tap to zoom

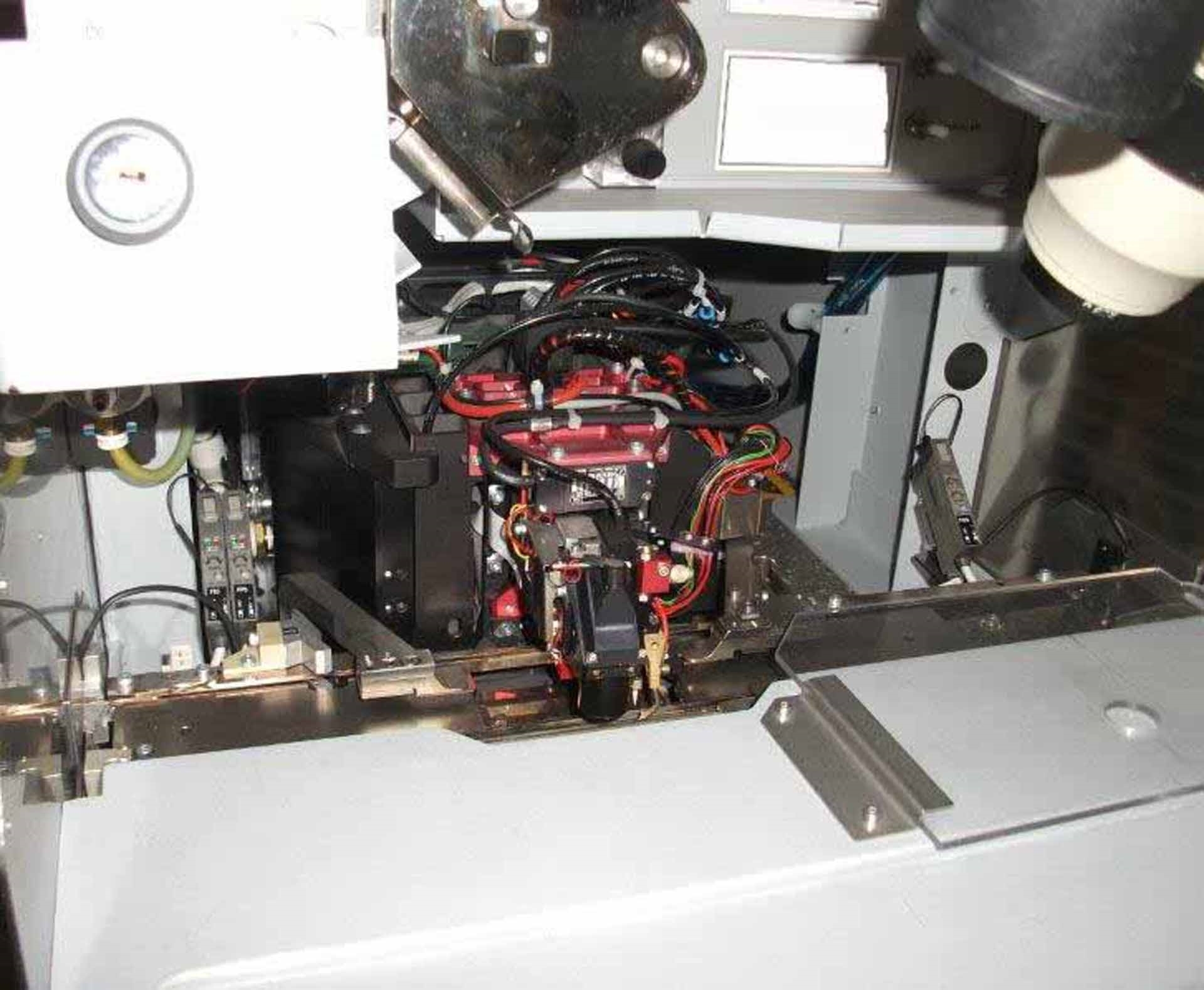

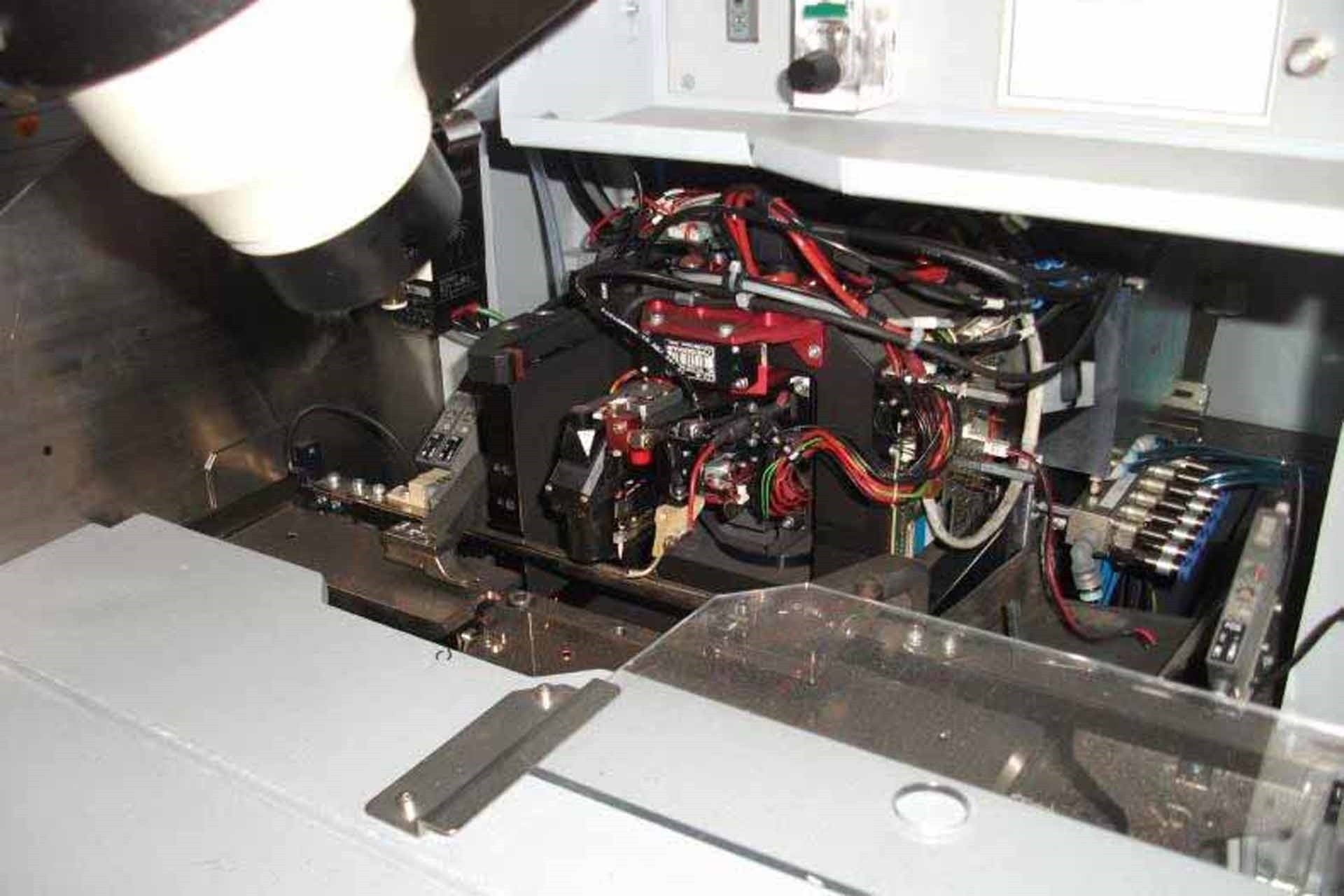

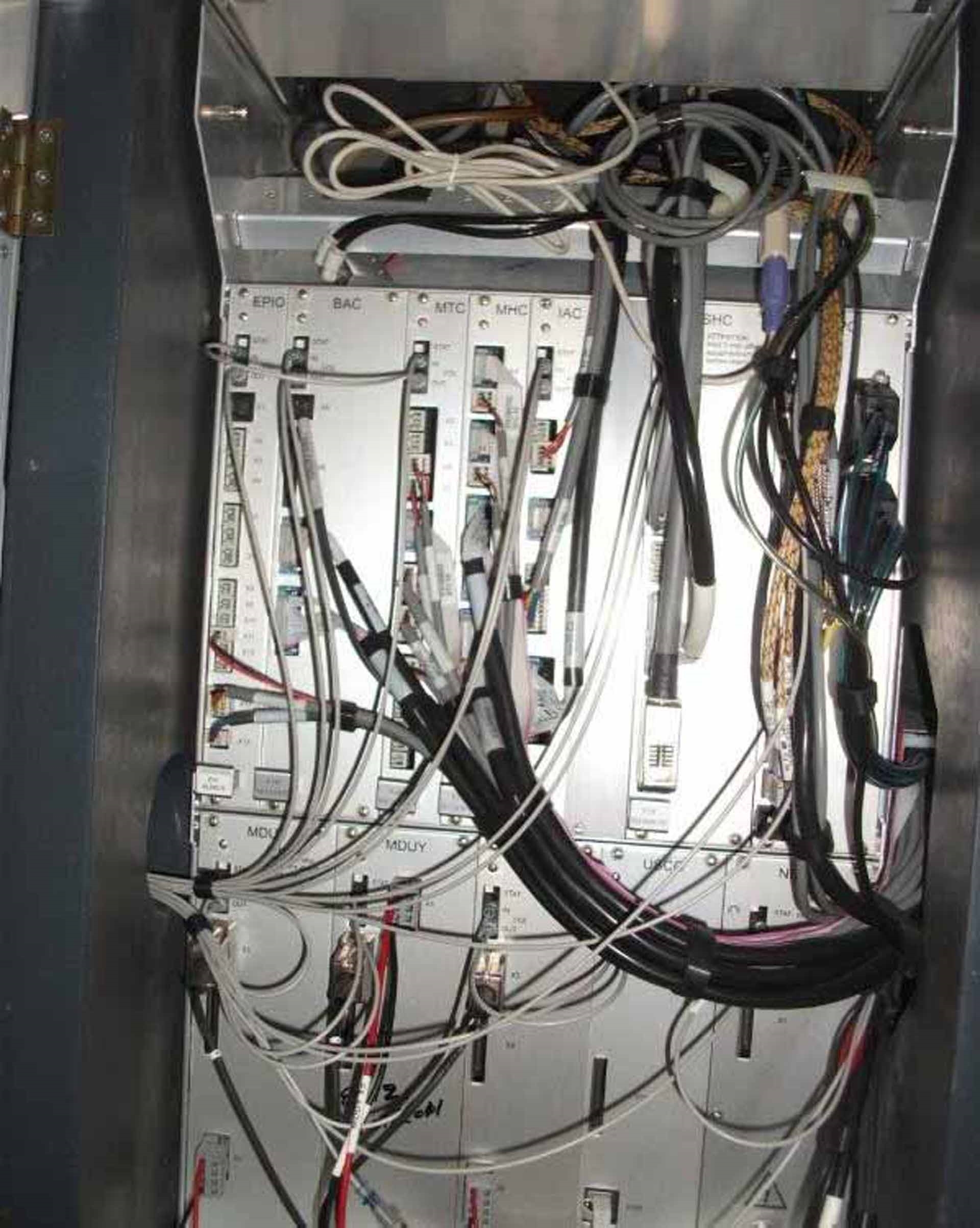

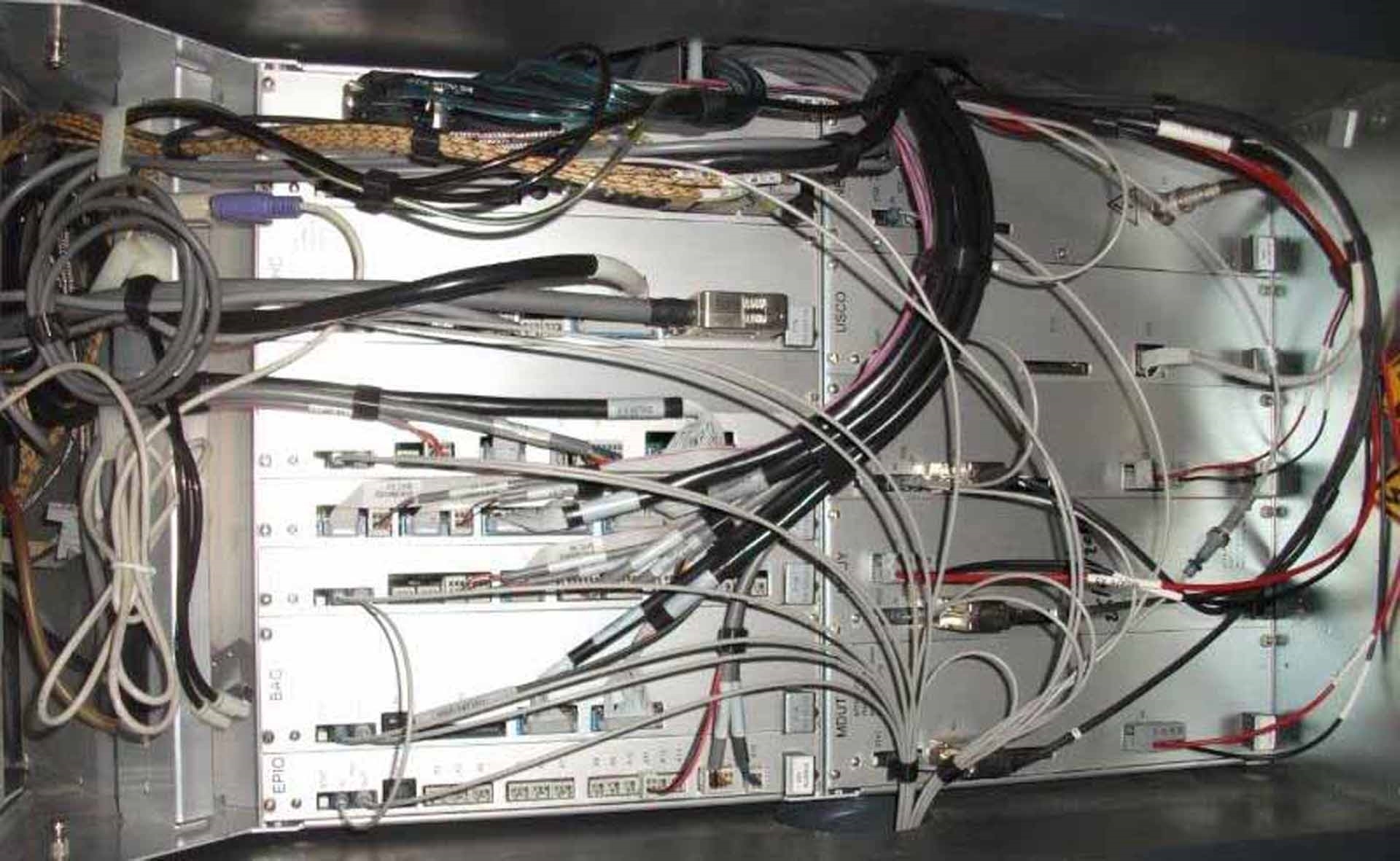

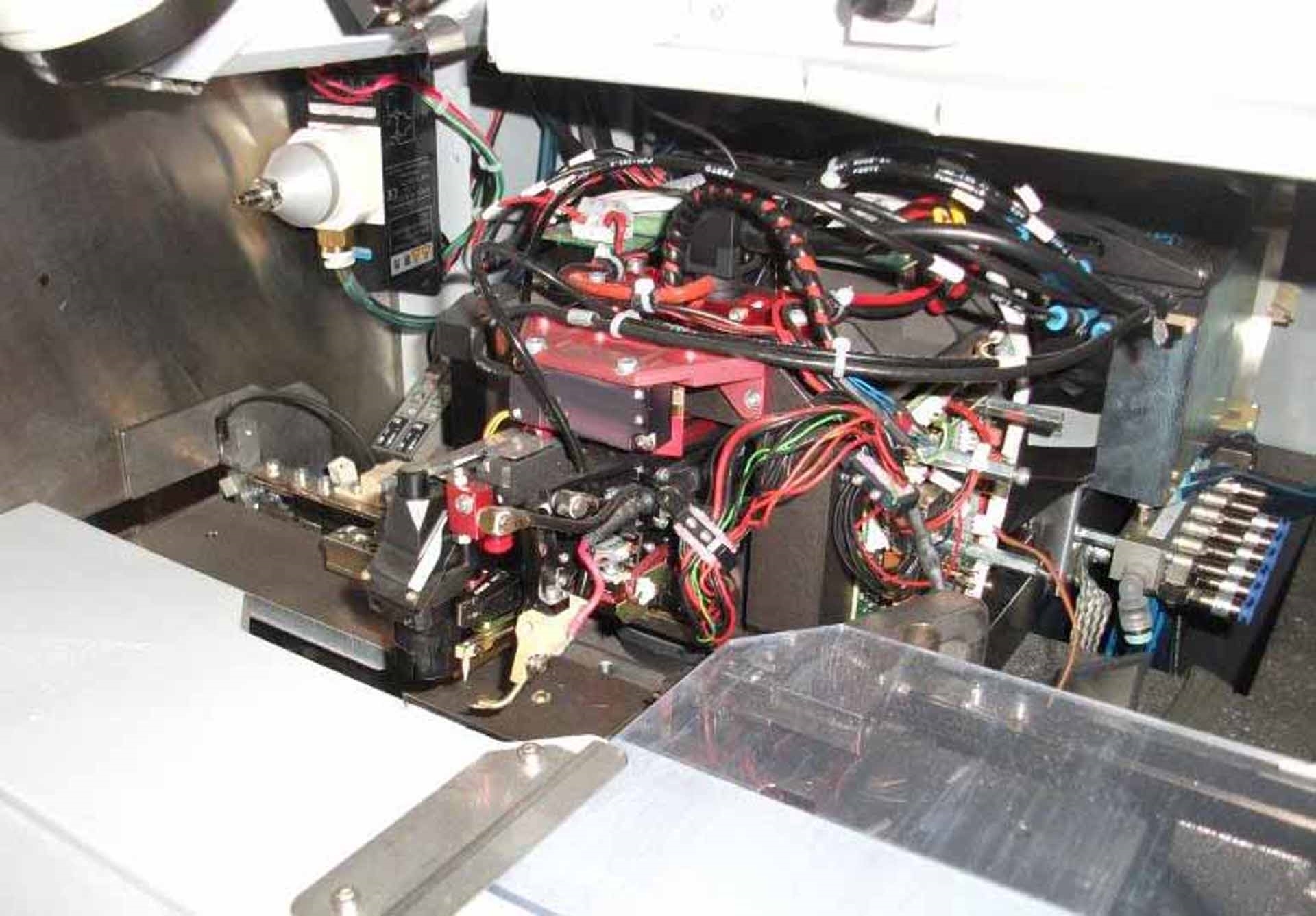

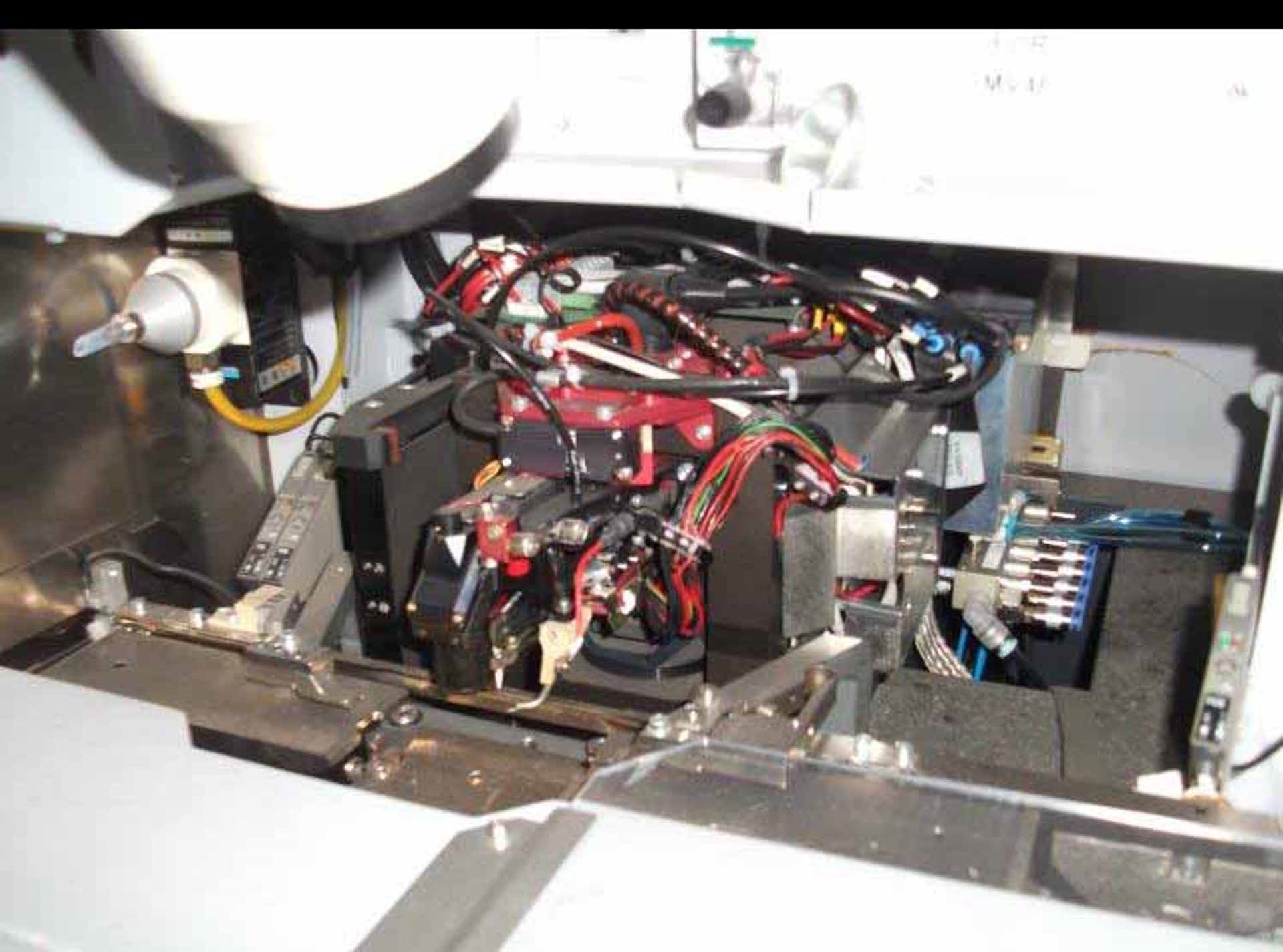

ESEC TSUNAMI W3100 is an automated bonder offering a reliable, high-speed solution for electronic board and assembly manufacturing. The machine is designed to provide secure, robust, and fast connections between component or boards. The unit uses an 12-axis robot arm to pick up and bond components to specific mating locations. W3100 is able to bond quickly and accurately with fine-pitch components, small-gnasher defects, and automated cleaning. It is also able to learn and store specialized paths for a variety of processes, as well as being able to handle components of any size. The use of coplanarity is employed to ensure repeatable and secure connections. The unit features user-friendly software that is simple to use and permits easy program creation and integration into various manufacturing processes. The software is modular for simple configuration when paired with multiple types of components. Additionally, ESEC TSUNAMI W3100 is capable of a wide variety of independent bond patterns and its integrated vision system is designed to provide reliable, repeatable results. The Tsunami W3100 has the capability to process a wide range of boards including high-density substrates and circuitry. A variety of die attach and IC bonding methods are available for customization, such as epoxy, polyimide, and gold wire bonding. In addition, this automated bonder features a user-replaceable drum feeder system that allows for the continuous operation of manufacturing lines with minimal downtime. To ensure quality and performance, the Tsunami ESEC TSUNAMI W3100 has been designed for highly reliable performance under extreme environmental conditions. This unit is also designed for long-term endurance with minimal maintenance requirements. Lastly, W3100 is RoHS and REACH compliant, making it an ideal choice for meeting regulatory standards in most countries.

There are no reviews yet