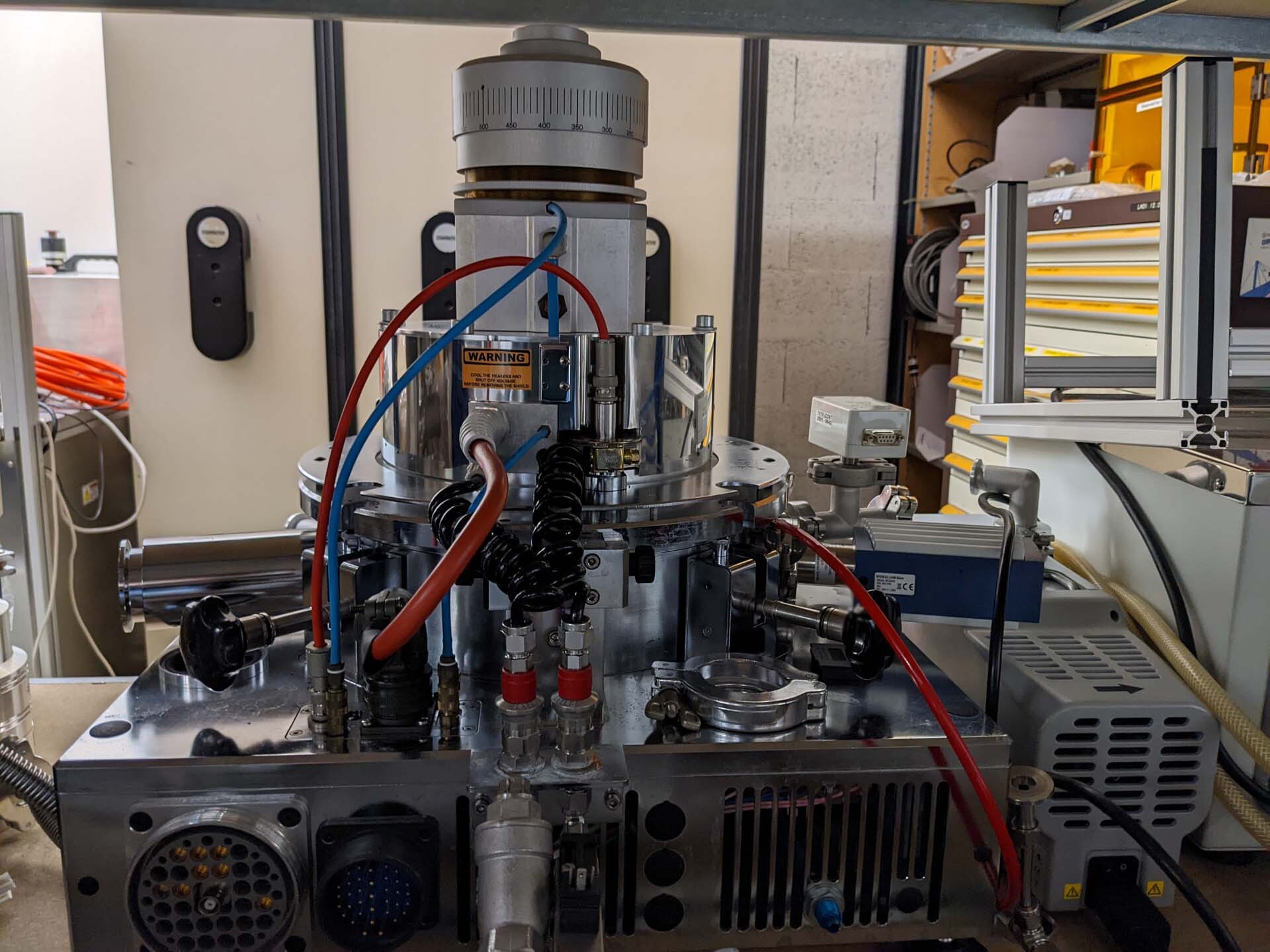

Used EVG / EV GROUP 501 #293605315 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

EVG / EV GROUP 501 is an automated wafer bonder designed to bond multiple and/or single dies to substrates in a controlled, safe, and repeatable manner. It is a fully automated solution for die-to-substrate bonding and offers a wide range of features and capabilities, including wafer stacking and back-grinding capabilities. EVG 501 is built for production capacities and is ideal for the development of 3D-ICs, MEMs, microfluidic devices, and other complex microelectronic structures and systems. EV GROUP 501 utilizes the latest in high-accuracy die-to-substrate and wafer-to-substrate alignment technology in combination with robust and reliable bond metrology. This ensures reliable and repeatable process results and minimized bonding times. Its proprietary imaging algorithms optimize the accuracy of alignment, even in challenging process conditions. The equipment offers excellent precision and fine control of the bonding process parameters, including pressure, temperature, and time. The algorithm-based design enables optimal pressure distributions, force responses, and velocity control during the bonding process. The system accommodates a wide range of wafer sizes and substrate thicknesses, including thin wafers and 6-mil foil substrates. The automated bonding process includes a complete environmental control setup for temperature, humidity, and cleanliness, as well as an integrated camera unit for high-resolution imaging. The integrated vision machine enables positionindependent operation, allowing for larger bondfields and faster production rates. The tool is also equipped with a powerful and intuitive software interface that allows for easy setup and monitoring of process variables. 501 has a robust, ergonomic design with a built-in cooling asset, making it suitable for use in both cleanroom and production floor environments. The model is designed with the latest safety standards and provides secured access levels to protect confidential data. The equipment is also equipped with numerous user-friendly features, such as advanced teaching and programming, wafer registration, and in-process diagnostics for improved quality control. Overall, EVG / EV GROUP 501 is an ideal high-precision, automated wafer bonder that provides an economical, efficient, and reliable solution for die-to-substrate and wafer-to-substrate bonding. It offers fast and repeatable bonding cycles, reduce cost, and high yields. The system is robust, ergonomic, and equipped with numerous advanced features and capabilities, making it an ideal choice for high-volume production and/or advanced microelectronic applications.

There are no reviews yet