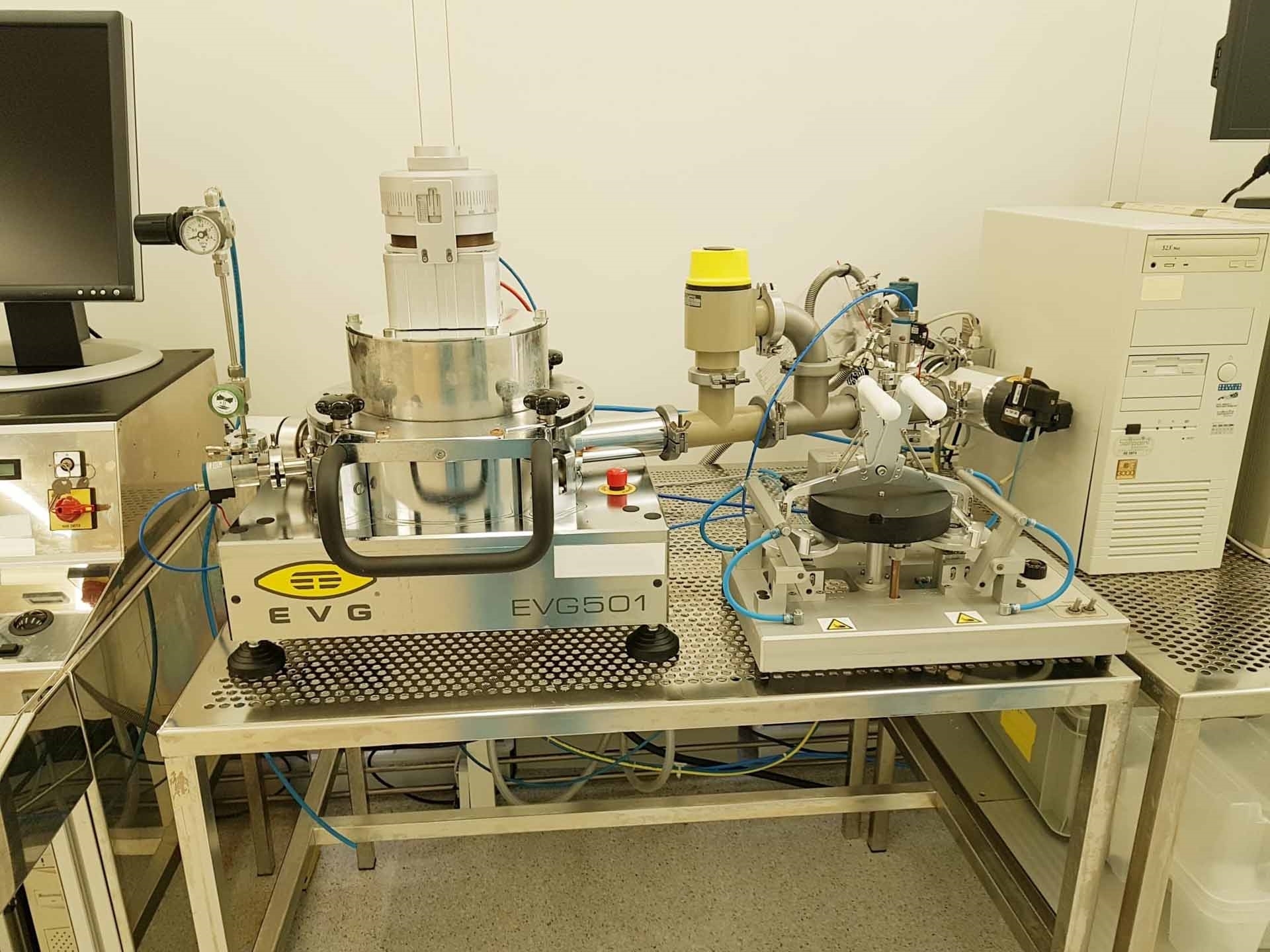

Used EVG / EV GROUP 501 #9256745 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

EVG / EV GROUP 501 is an amorphous-substrate, mid-range precision wafer bonder. It is designed for medium-power flip-chip, stacked die, optical die-attach, and assembly applications. The unique design of EVG 501 ensures a sealed processing chamber, allowing bonded substrates to be processed at atmospheric pressure. The locally adjustable heat-zone configuration accelerates processing efficiency and reduces thermal distortions. Heating elements are adjusted to temperature levels with an accuracy of 0.1°C. This ensures precise positional accuracy and repeatability for maximum yield. EV GROUP 501 is designed for flexibility, containing a number of versatile features including programmable multi-axis motion, multi-standoff settings, and 4-point cassette grippers for substrate holding. Its built-in cold-pedestal and lift module options provide easy tooling and fixture changes. The bond head also features a fine-pitch actuator equipment that allows for precise placement of components. For precise processing control, the bonder is equipped with a 78-point electronic optical microscope and 0.1 μm encoders for each of its six axes. It also provides for accurate temperature control. Temperature, pressure, and particle control parameters are monitored and stored in the bonder's data logging system for repeatable processes. 501 contains a host of user-friendly software and hardware features. EVG BondTube™ software provides fully automated workflows and convenient user interfaces for set-up, testing, and monitoring of process runs. Additionally, its real-time control unit makes autonomous improvements during process runs. EVG / EV GROUP 501 minimizes particle contamination, enabling users to ensure highly reliable and clean bonded substrates. It is certified for Class 10 (ISO/EC/EN 61340-5-1) clean room operation and features an efficient pump machine that handles up to 500 liters/min of process gas. For added convenience and cost savings, the bonder is equipped with optional connection to a lightweight droplet deionization (LDI) deionizing filter and a self-monitoring flow meter and alarm. With both power and nitridation options, users can achieve well-aligned, high-quality bond lines for both new and repeat jobs. Overall, EVG 501 is an advanced yet cost-effective wafer bonder that provides users with highly precise processing control and reliable substrate bonding.

There are no reviews yet