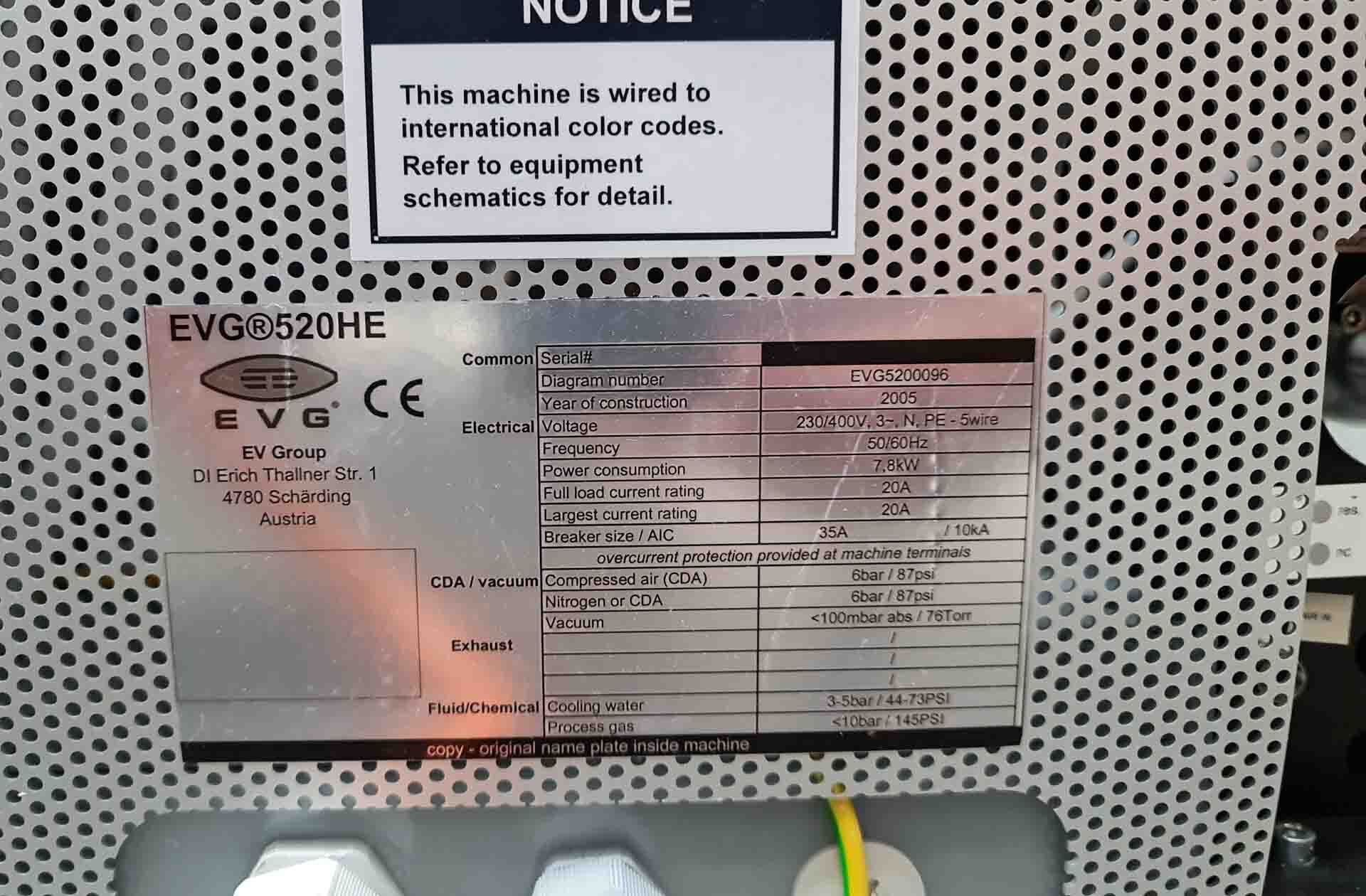

Used EVG / EV GROUP 520HE #293667074 for sale

URL successfully copied!

Tap to zoom

ID: 293667074

Vintage: 2005

Sealer

Standard process chamber

Control unit

PC

Handling tool for unloading of hot tools

Cooling station:

Unloading mechanism

Storage area

Process chamber:

Standard bond

Embossing chamber

Bottom side heater, 8"

High pressure cover with top side heater

Double sided heating: Up to 350°C

Atmospheric capability: 0.1 mbar (1 x 10^-3 mbar (7.5 x 10^-4 Torr] with optional turbo molecular pump)

Purge time: < 10 sec from high vacuum to 1 bar

Pressure: 3 bars

Hydraulic unit: 40 kN (9000 lbf)

Hydraulic piston assembly

Hydraulic pressure converter with gauge

Cover clamps

Stainless steel cover

(3) De-embossing pins for parallel and angular stamp lift-off

De-embossing force parallel: 120N, angular: 40N

De-embossing temperature: <200°C

Temperature controllers

Electronic pressure regulator

Valve controller

Dry roughing pump with connectors and valves

Operating system: Windows

2005 vintage.

EVG / EV GROUP 520HE is a wafer bonder, or die bonder, designed for efficient micro-electronic packaging. It is part of the range of EASY evaporator systems from EVG (EV GROUP) and offers a high-yield, reliable bonding process for the miniaturization of electronic assemblies. EVG 520HE is a fully automated bonder for applications ranging from flip chip, ball-grid array, or MEMS assembly to wire bonding / gold ball bonding. It has a modular design so users can customize their bonders as needed and it is suitable for prototyping, production, and R&D. Its robust mechanics ensure precision and accuracy, allowing it to work with a wide range of materials. EV GROUP 520 HE combines existing features such as variable-force and free-float bonding, an integrated vision system with 4-way alignment, and an electrical monitor system, to provide the highest yields and fastest cycle times. EV GROUP 520HE’s mechanical stage is equipped with an adjustable and steerable lower blade and a stable bonding platform with a minimum movement of just 0.1 µm. This ensures precise dispersion of small and delicate adhesive beads for small and fine chips. The axis setup and computer software are fully integrated, allowing up to six axes of movement for greater accuracy and higher yields. 520 HE is designed to be user-friendly and its controls can be customized based on profile to provide simplified operation and maximum productivity. In addition, dedicated software supports profile flexibility and accuracy with precise, repeatable motion. An intuitive graphical user interface allows easy and quick programming of complex bonding strategies. EVG / EV GROUP 520 HE has been used successfully for a wide range of applications, such as advanced packaging, flip-chip, and wafer-level packaging. With its reliable, accurate, and precise performance, it is an ideal choice for applications that require reliable and repeatable bonds. It is also extremely durable, providing a long life for reliable production and optimized yields.

There are no reviews yet