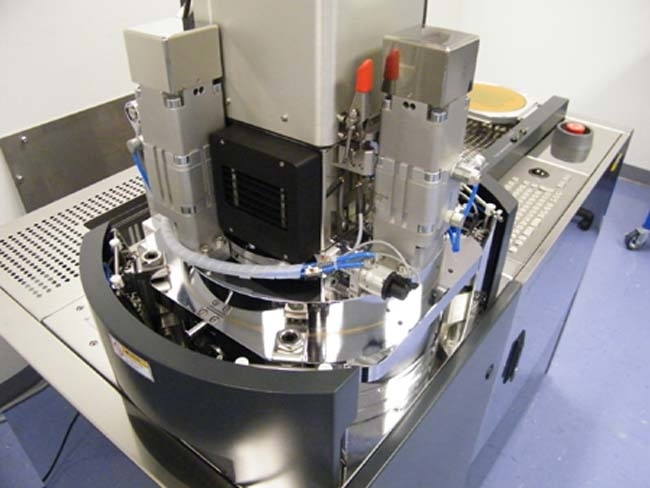

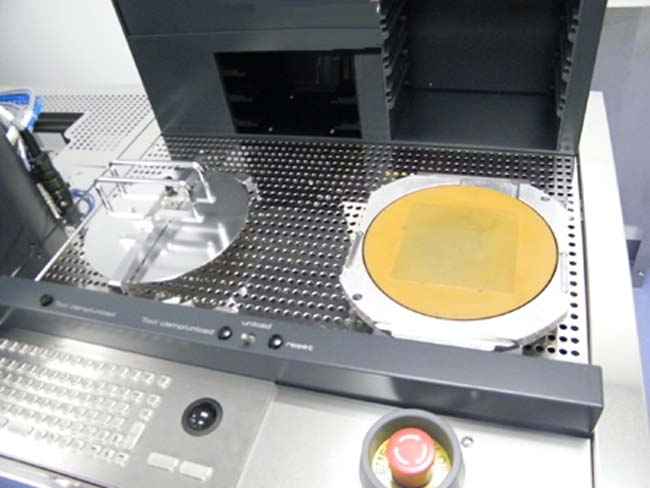

Used EVG / EV GROUP 520IS #9229813 for sale

URL successfully copied!

Tap to zoom

ID: 9229813

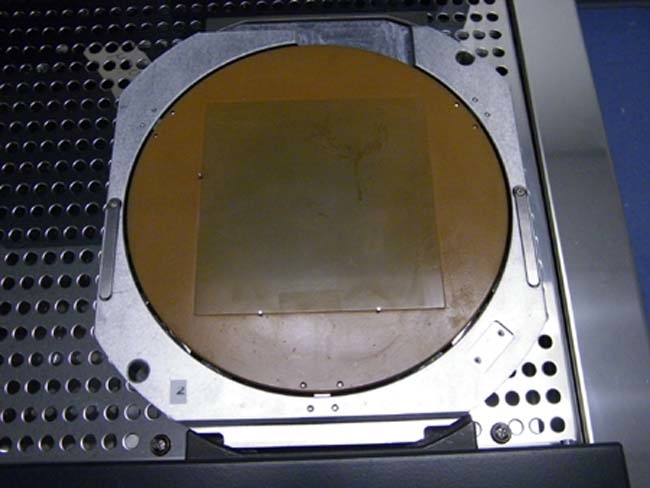

Wafer Size: 8"

Vintage: 2007

UV-NIL Bonder, 8"

UV Cured adhesive bonding / embossing in vacuum

High aspect ratio embossing and multiple de-embossing

Transparent cover with bellows for uniform contact force application up to 3.5 k N

Bond module:

Max over pressure: Atmosphere for contact less pressurization of pre bonded wafer pairs

Maximum contact force created by one atmosphere pressure differential (<14.5 psi)

Atmospheric capabilities down to 1 x 10^-1 mbar (7.5 x 10^-2 Torr)

Pump time capability: <1 min from 1000 to 5 mbar

Purge time capability: <10 sec from high vacuum to 1 bar

Heating capability on bottom side heater

UV-Light source

400 W Light source for UV-adhesive curing (Wavelength: 300-500 nm)

Operations manual and documentation included

2007 vintage.

EVG / EV GROUP 520IS is a high performance industrial wire and hybrid bonding equipment used for the precision placement of aluminum, copper, gold and silver wire bonding to devices such as semiconductor dies, connectors, capacitors and other electronic components. This bonding system was specifically designed to handle the challenges associated with large die bonding, as well as directing its own high-speed vision systems. The sleek, innovative design of EVG 520IS allows for easy and safe operation by the ergonomically designed single- joystick controller. EV GROUP 520 IS offers a variety of bonding modes, such as ball, wedge and thermosonically-controlled ball-collapse (TBCB) giving the flexibility for various wire bonding applications. The bond head offers a maximum speed of 7 meters per second, which combined with the powerful software allows for high-speed accuracy, reliability and repeatability. The operator can easily select a constant speed, or program a variety of speeds ranging from 0.1 to 7 meters per second. The software makes it simple to optimize the loop form for a specific material and component combination. The software allows real-time replication of the bond process with preview of the formation to ensure precision and accuracy. Additionally, EV GROUP 520IS offers a Teach-In feature with corrected loop and programmed parameters all stored in non-volatile memory. The integrated vision systems of 520 IS provide precise die placement and control over the wire size, length and intersection angle. The operator can easily preset the position and height for each component prior to the bonding process to ensure accuracy. The redesigned chuck unit of 520IS provides optimal handling and durability, with enhanced thermal performance compared to its predecessor. EVG / EV GROUP 520 IS offers full compatibility with various OEM parts manufacturers, making it a great choice for die-level bonding processes. This machine is cost-effective since it uses only one tool for wire bonding, and its compact design saves on space, providing an optimized working environment. Furthermore, EVG 520 IS is backed by a two year warranty to ensure quality craftsmanship and performance.

There are no reviews yet