Used EVG / EV GROUP Gemini #293651184 for sale

URL successfully copied!

Tap to zoom

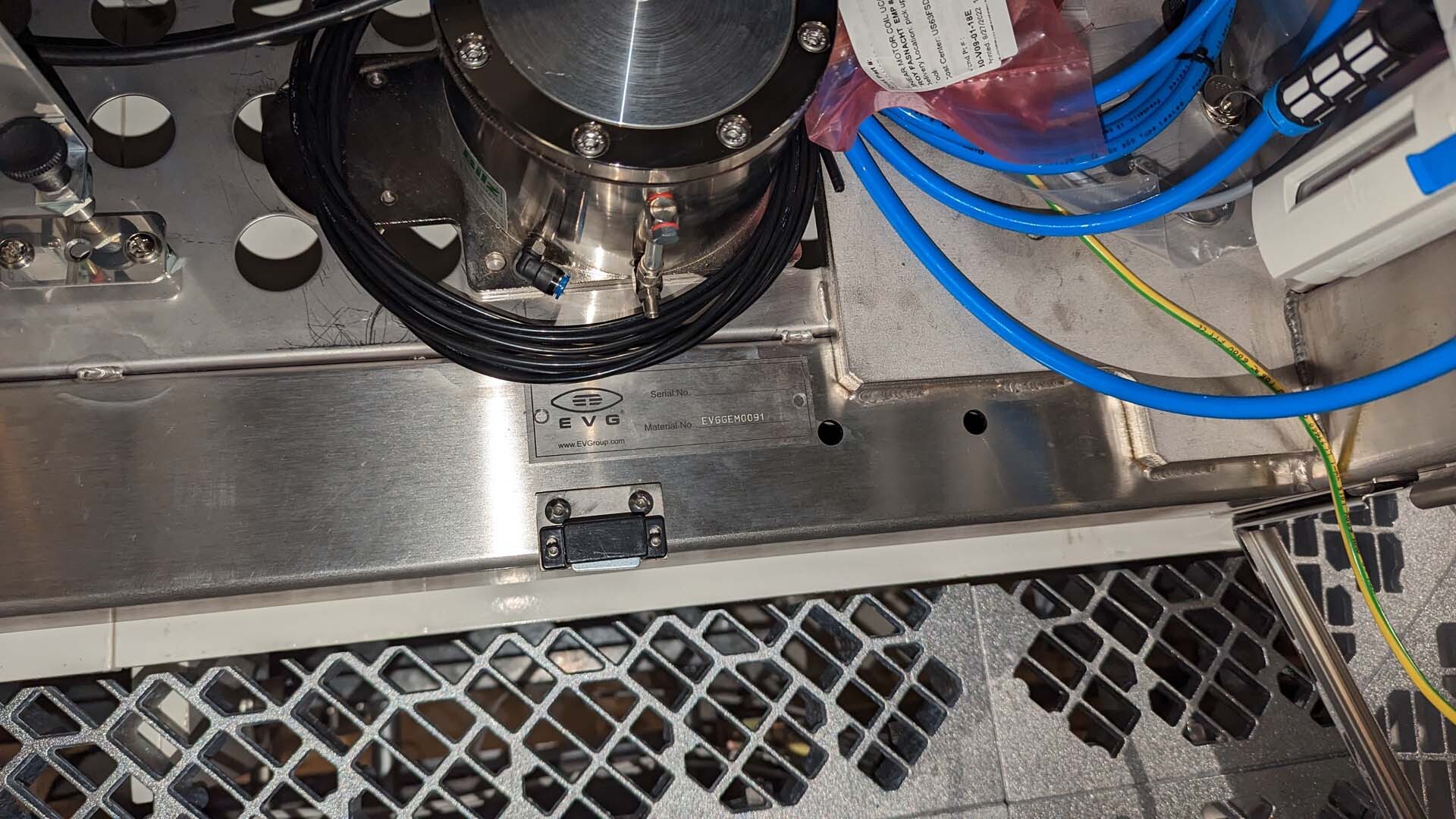

ID: 293651184

Wafer Size: 8"

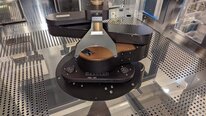

Vacuum bonder, 8"

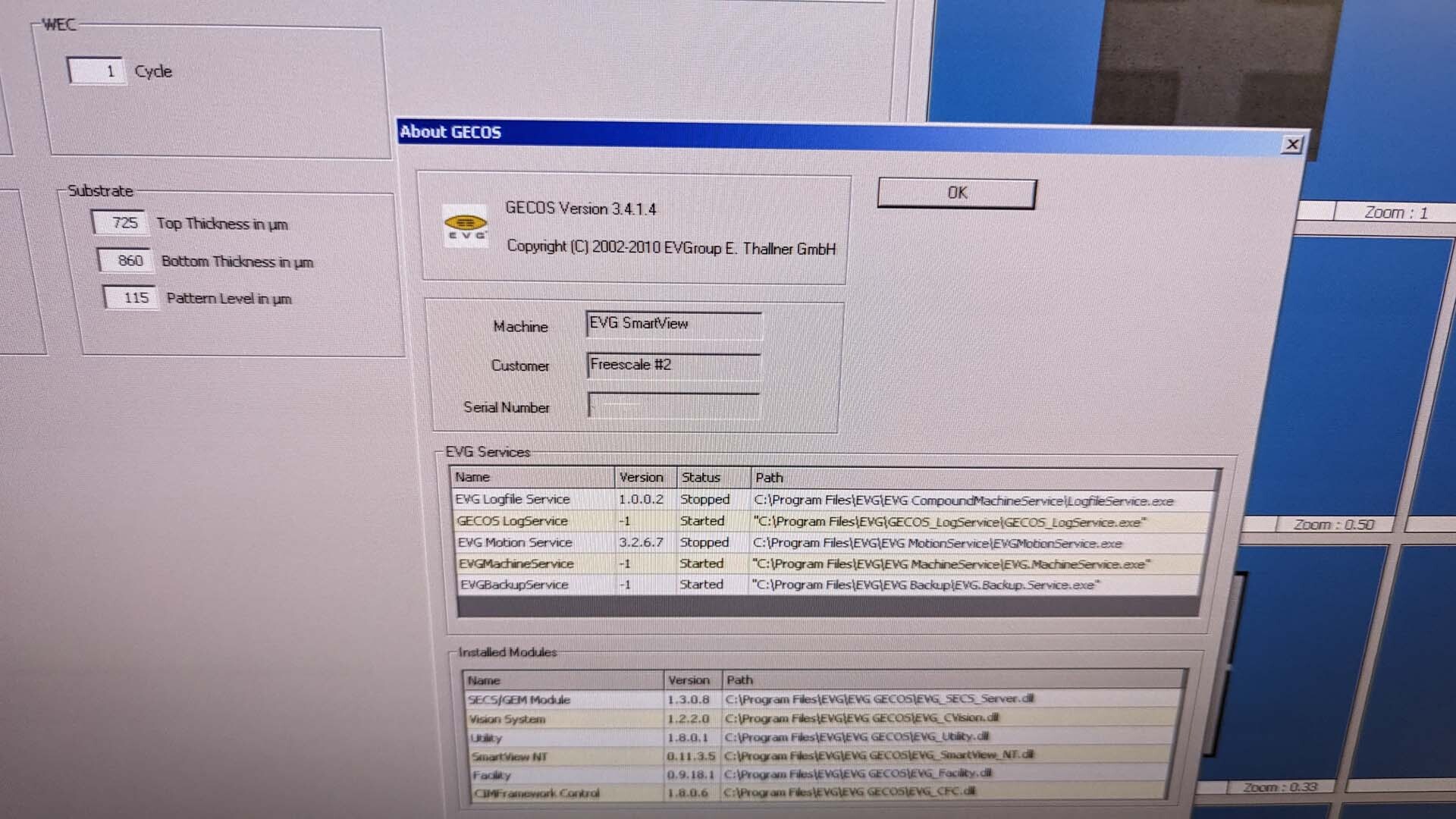

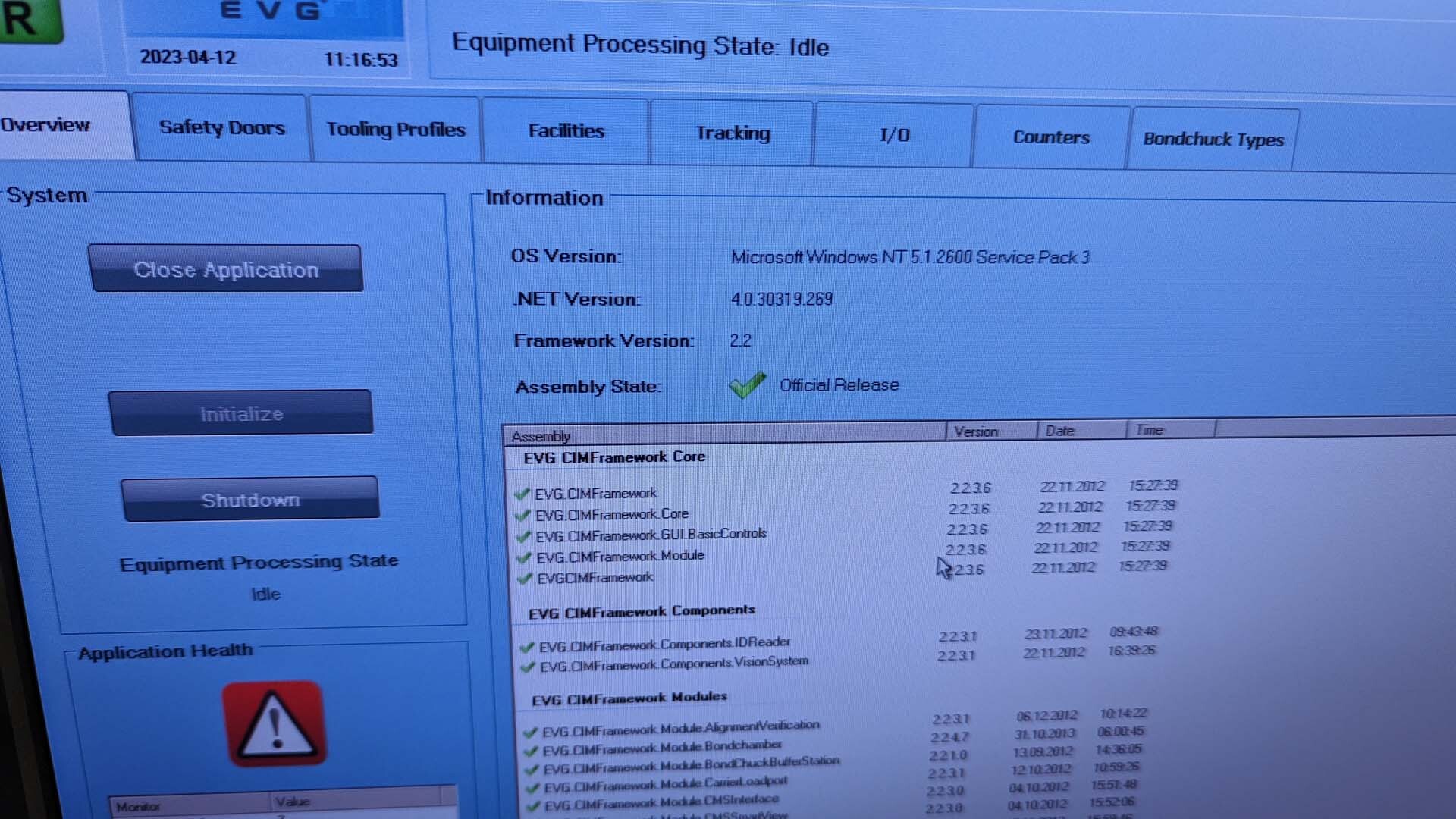

CIM: SECS II / GEM

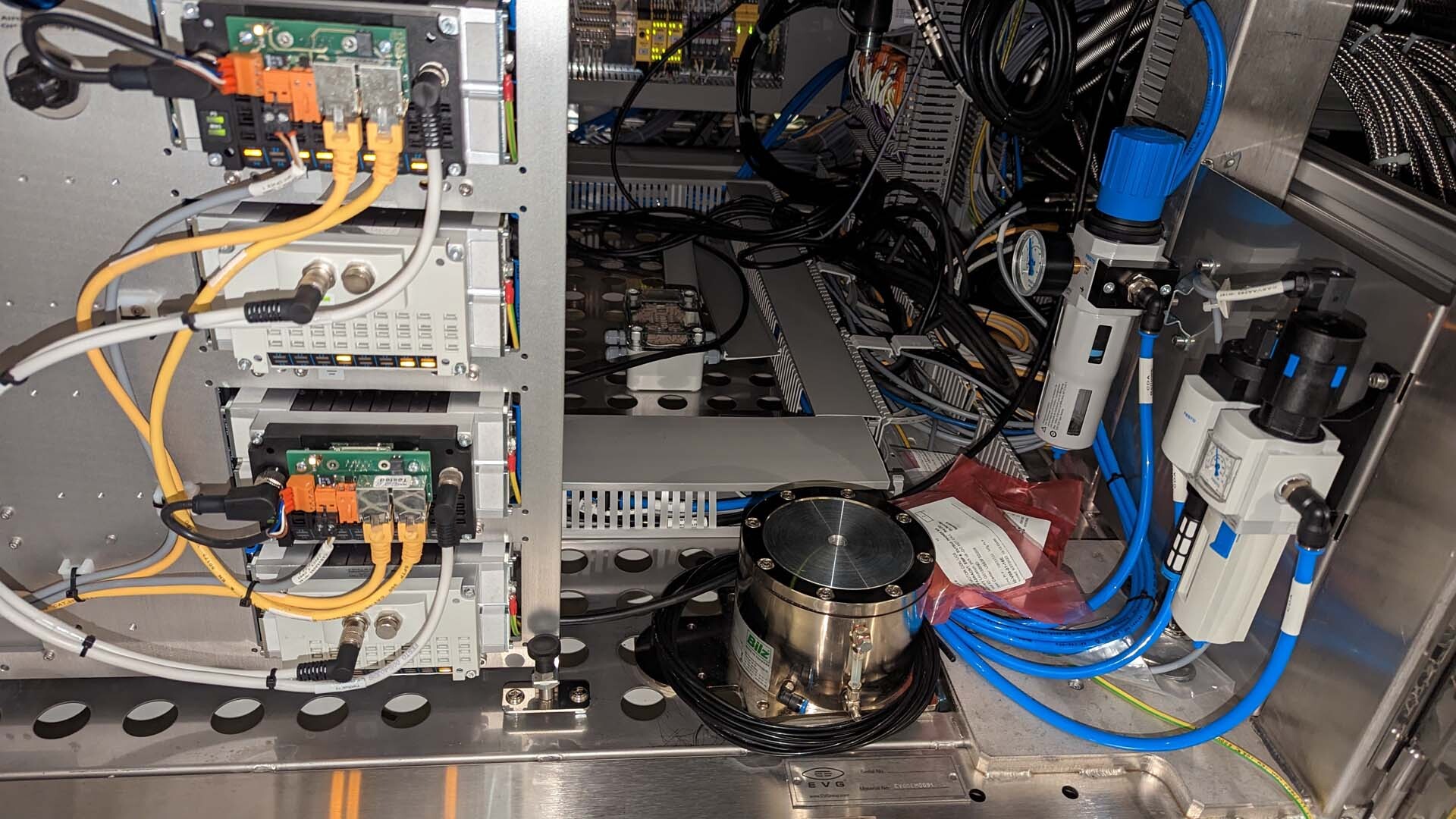

Solid State Drive (SSD)

Hard Disk Drive (HDD)

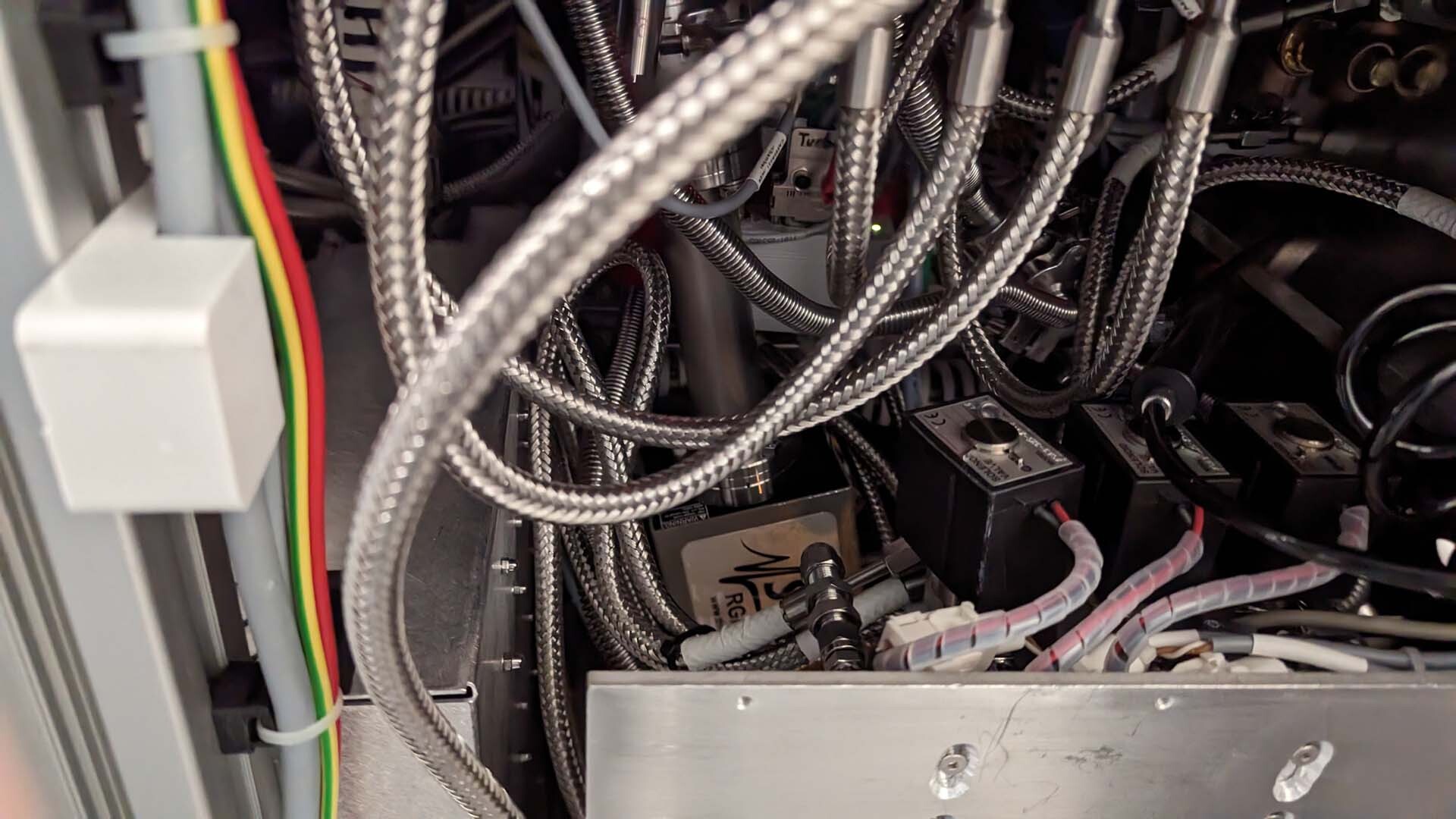

Control rack

Graphical user interface

DVD Backup system

Wafer ID Reader

CMO

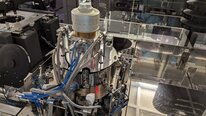

Turbo molecular pump with control unit

Turbo pump

Objective: 10x

Resolution: 3 N Steps

Gas backfill time: <10 sec

Purge connection

High resolution digital CCD Cameras

PC Control

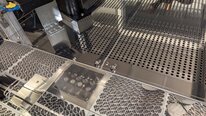

Oil-free roughing pump, capacity: 5.4 m³/h (50 Hz), 6.6 m³/h (60 Hz)

Ultimate chamber vacuum: 0.1 mbar

Purge gas:

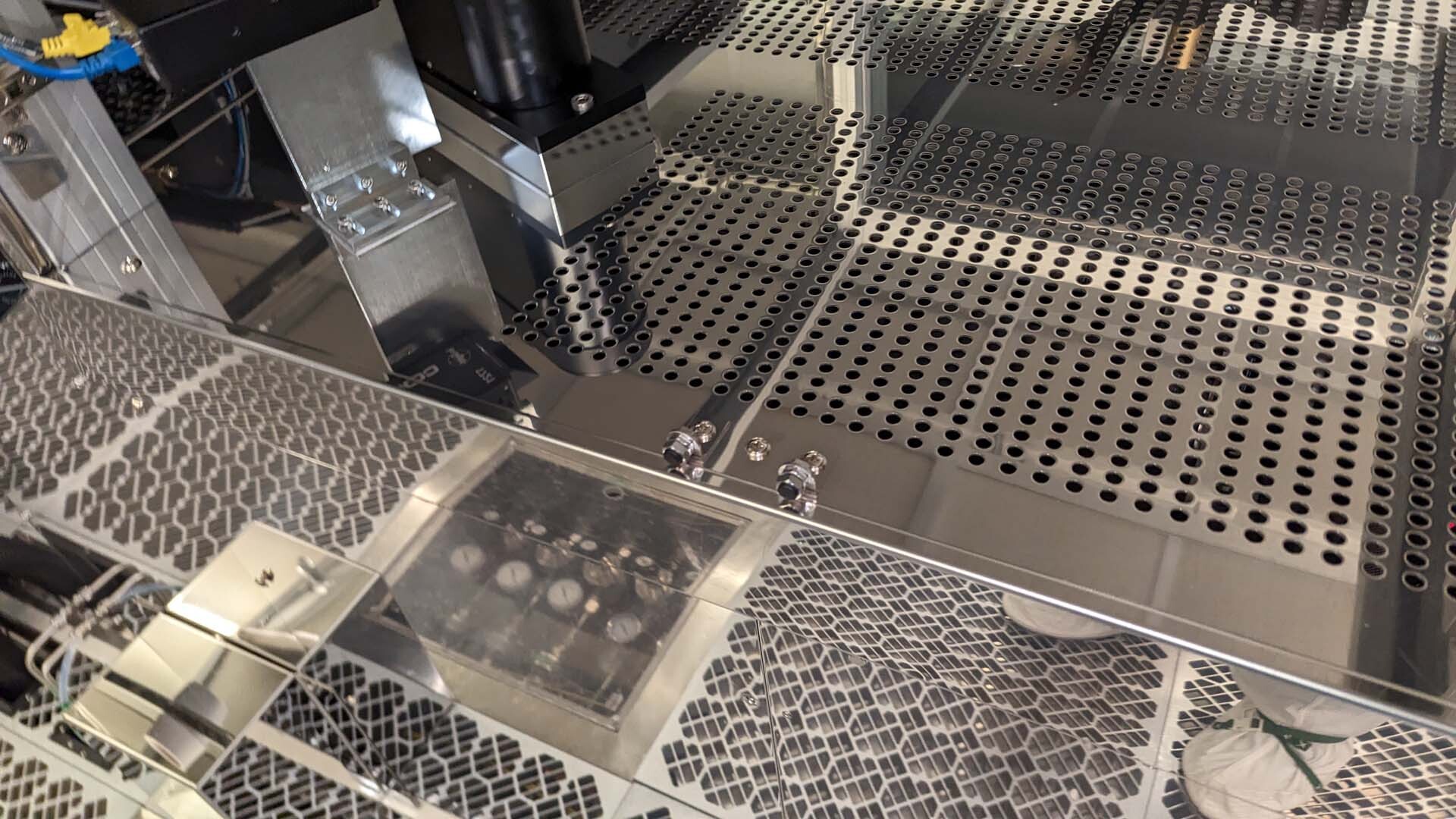

Mass Flow Controller (MFC)

Gases: N2, He, Ar, N2, H2

Analog pressure gauge

Range: 0-10 bar

Resolution: 0,2 bar

High purity pressure regulator

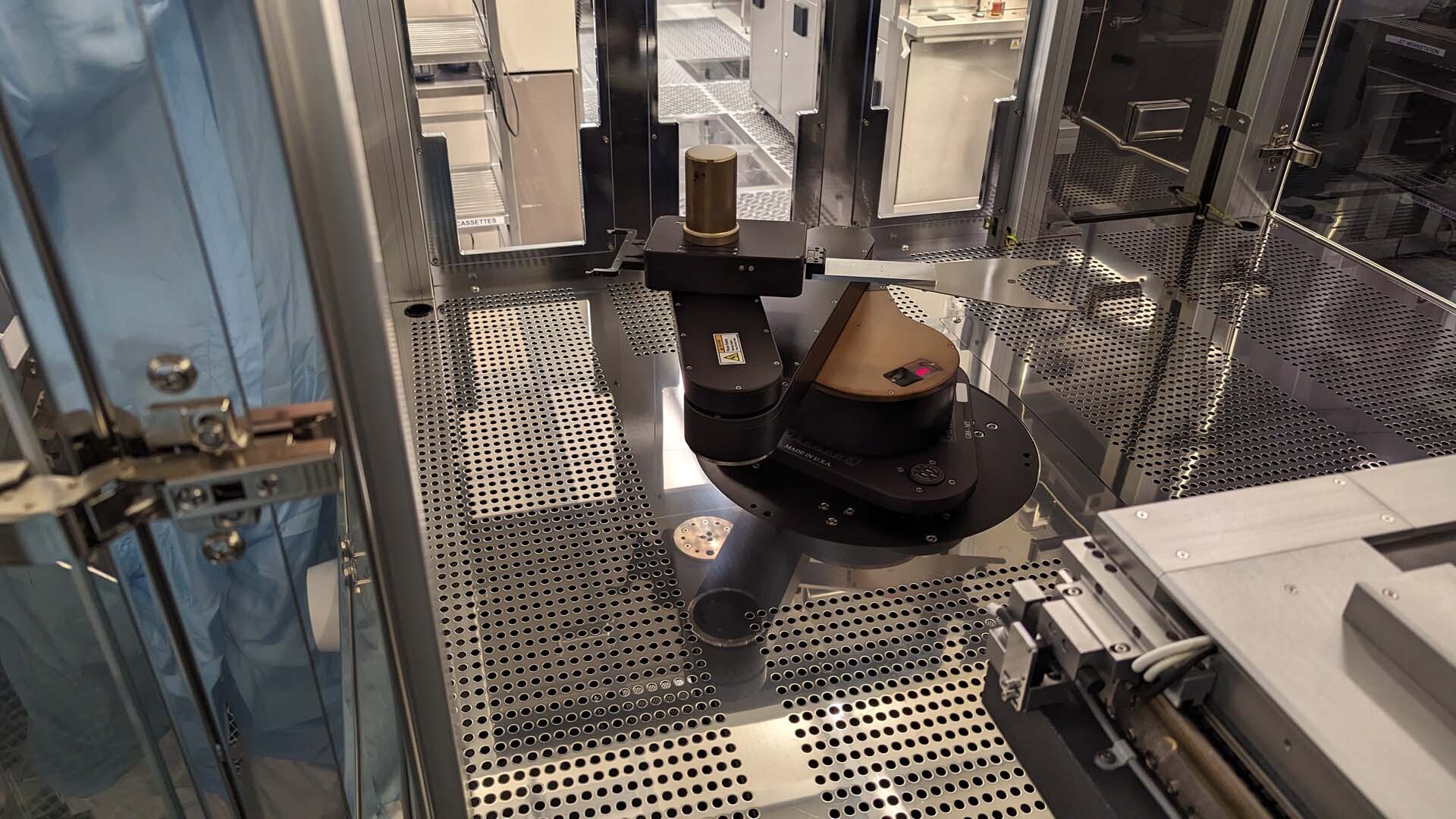

Alignment unit:

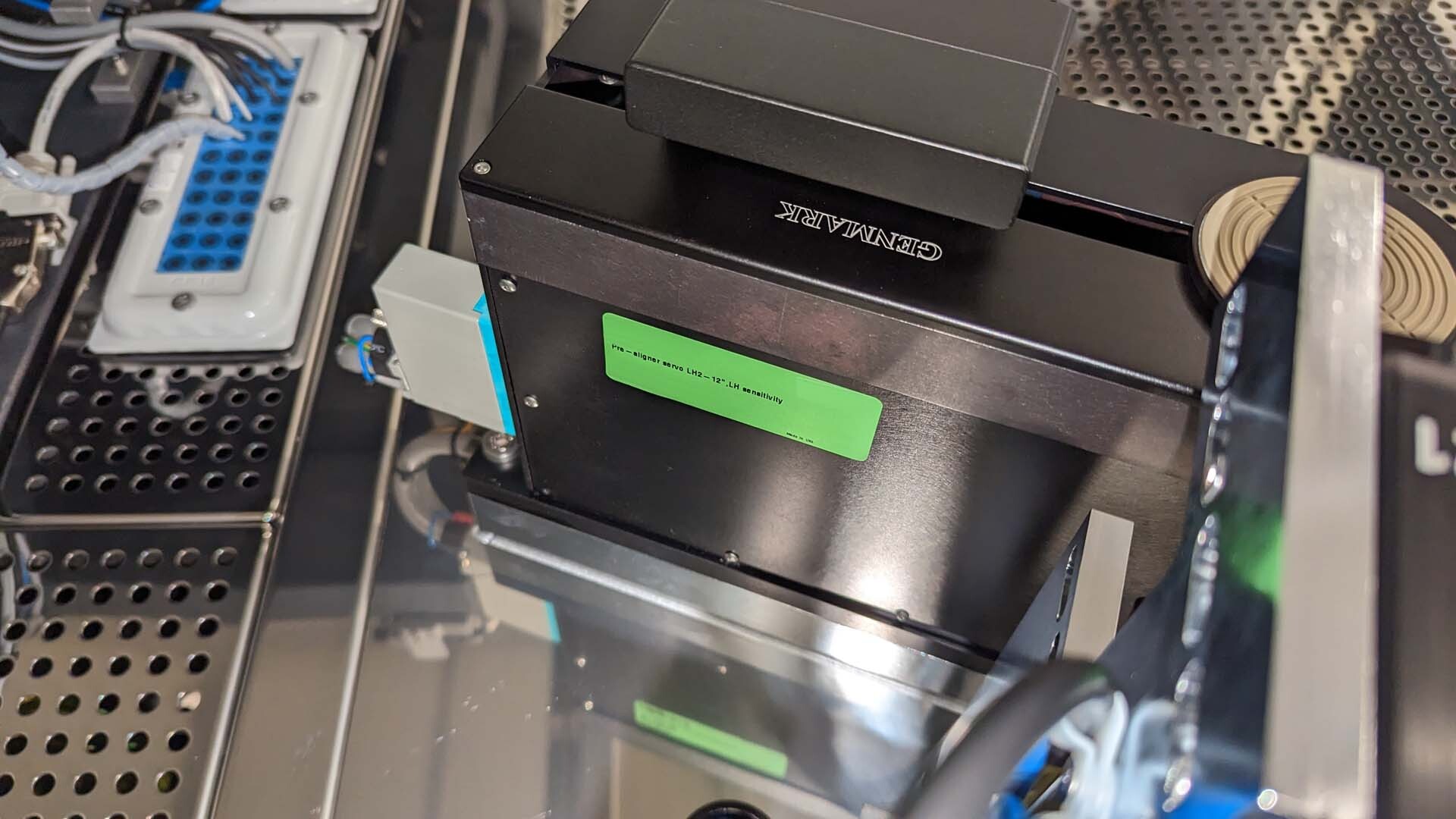

High resolution alignment stage with DC Servomotors

Top and bottom wafer chuck with position measurement system

Joystick control

(3) Spindle alignment stages

Measurement system

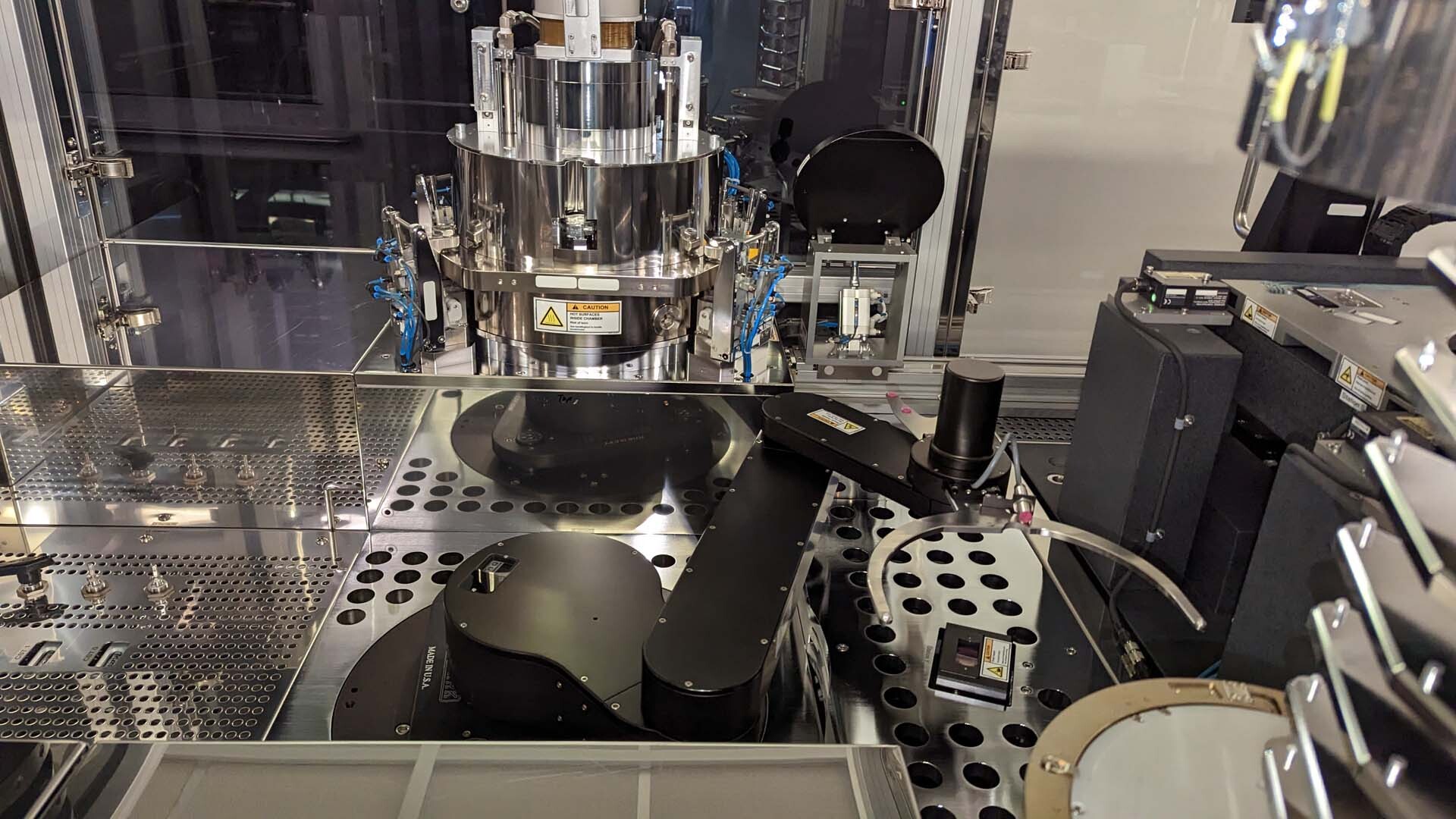

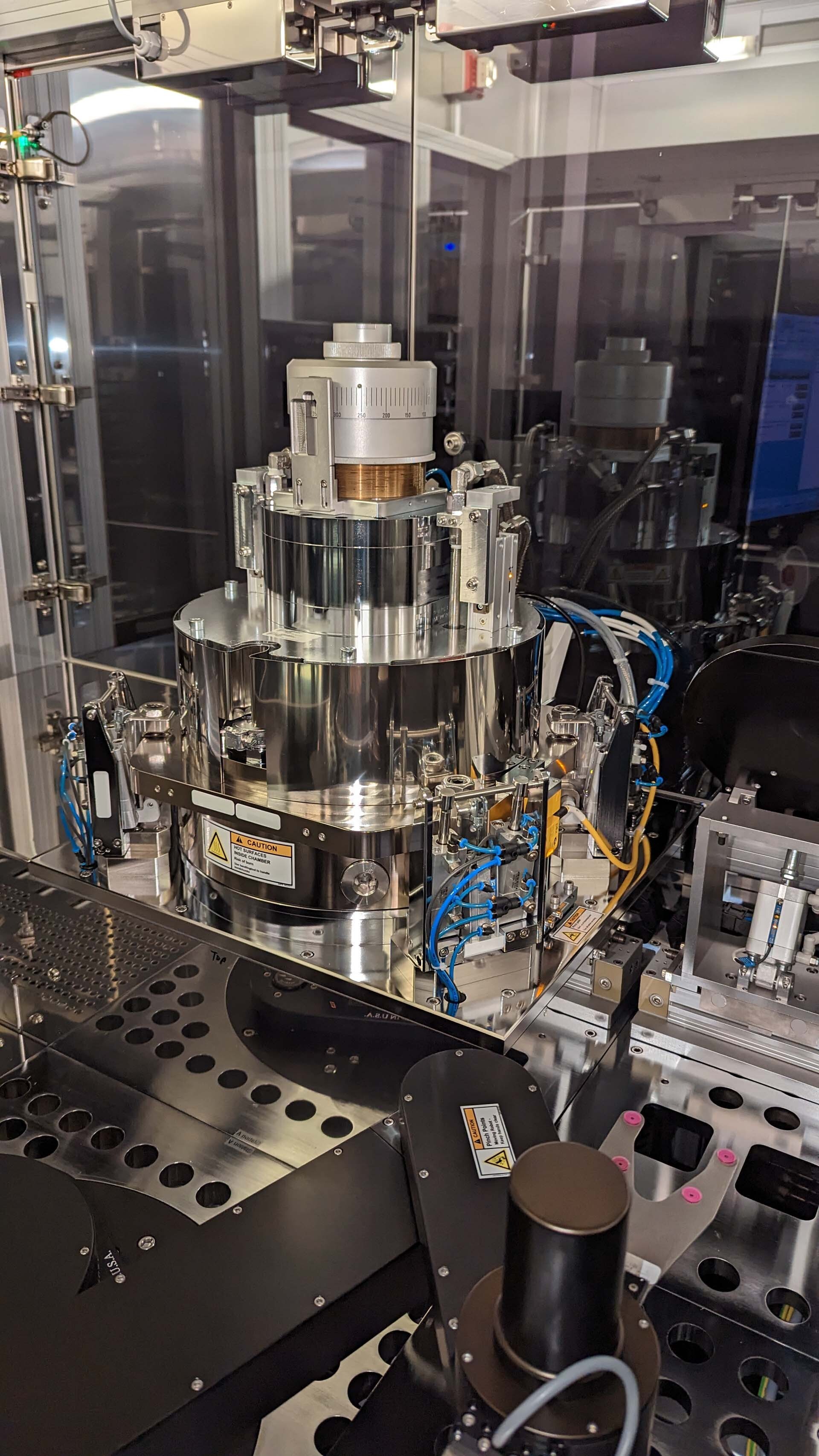

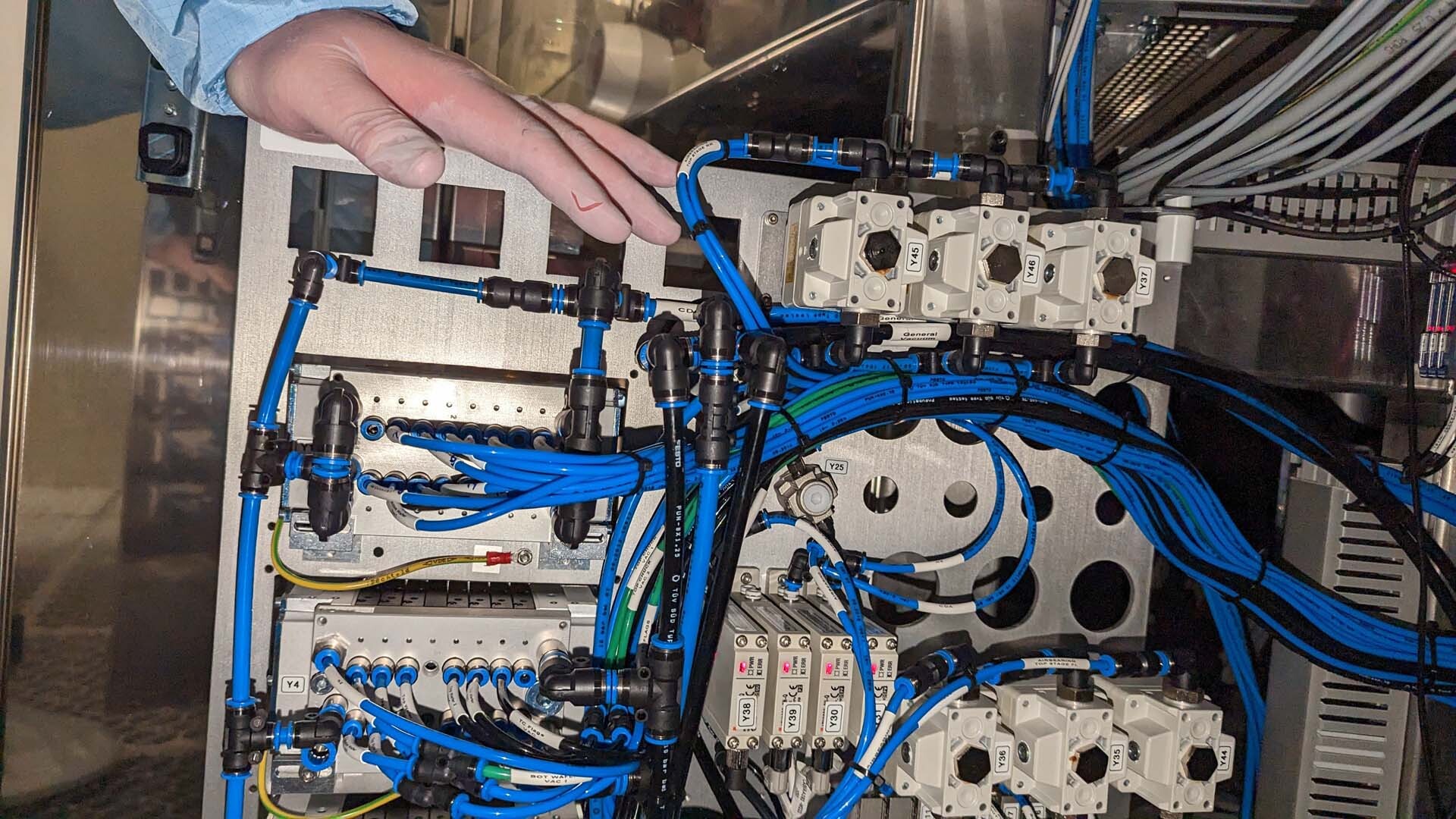

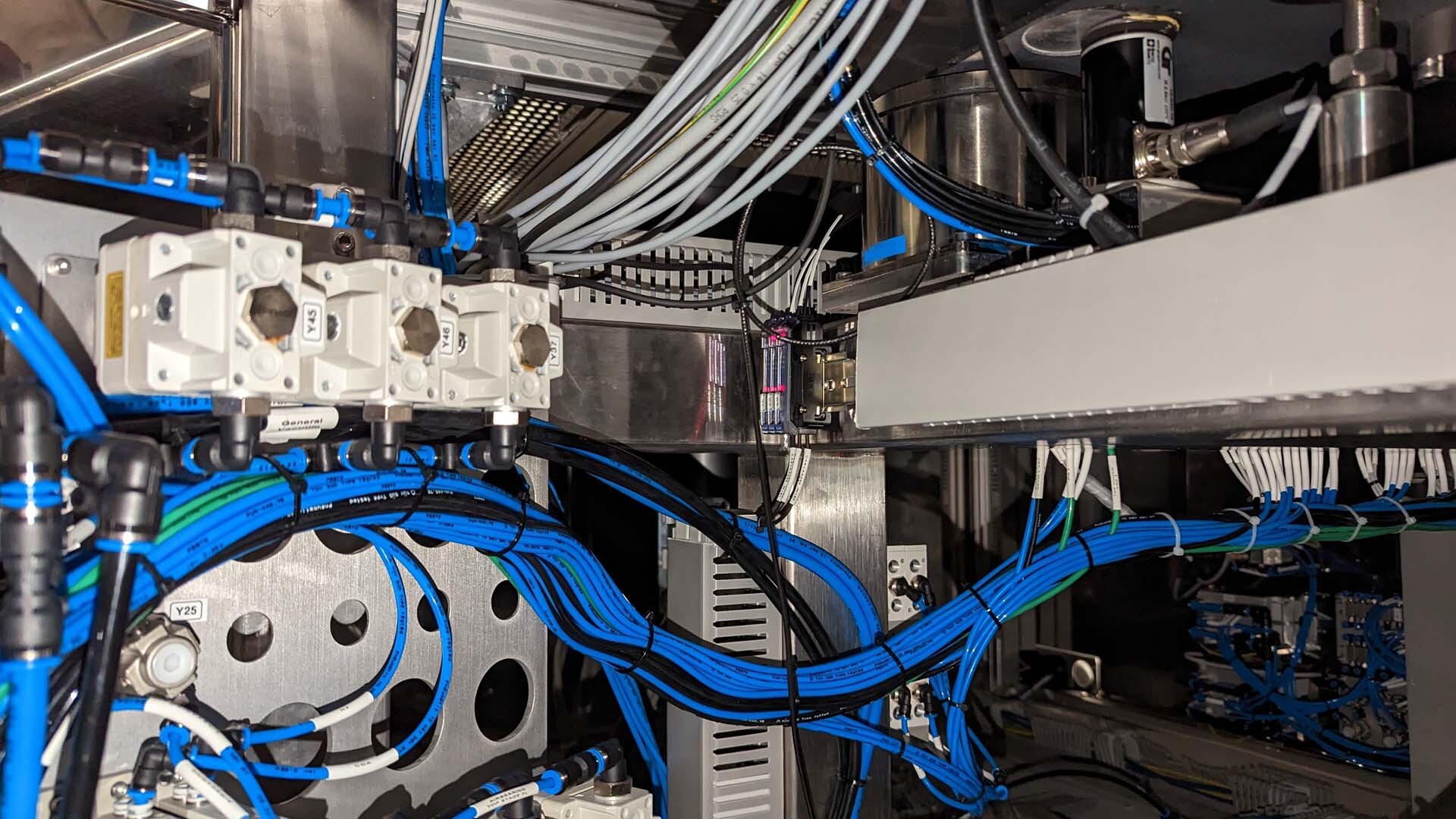

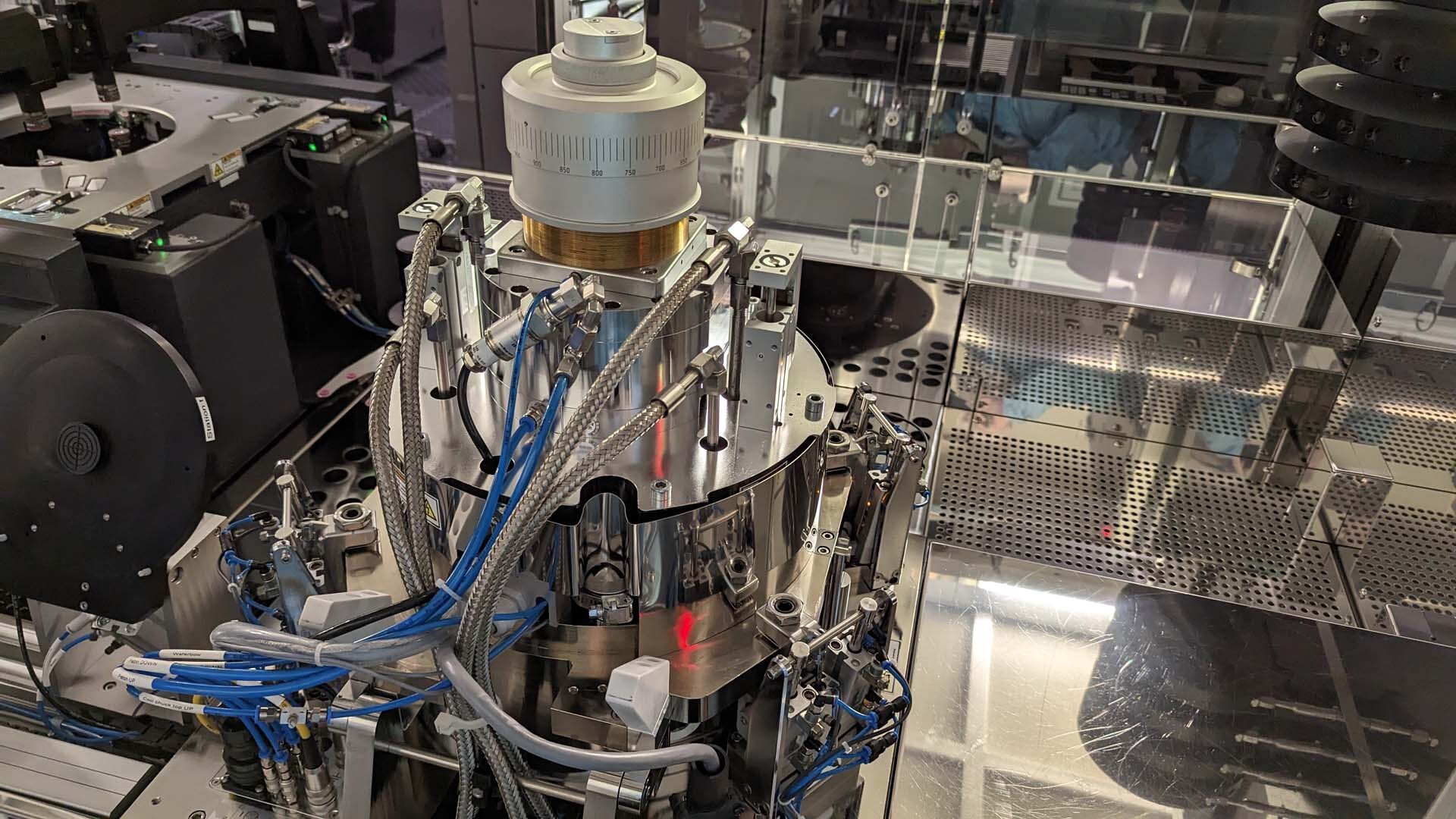

Bond module:

Bond chamber with top and bottom side heaters

Process: Up to 550°C and 3.5 kN

Pressure: 3 bar

Temperature controller

Electronic pressure regulator

Rapid cooling system

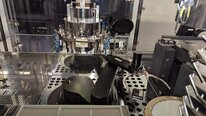

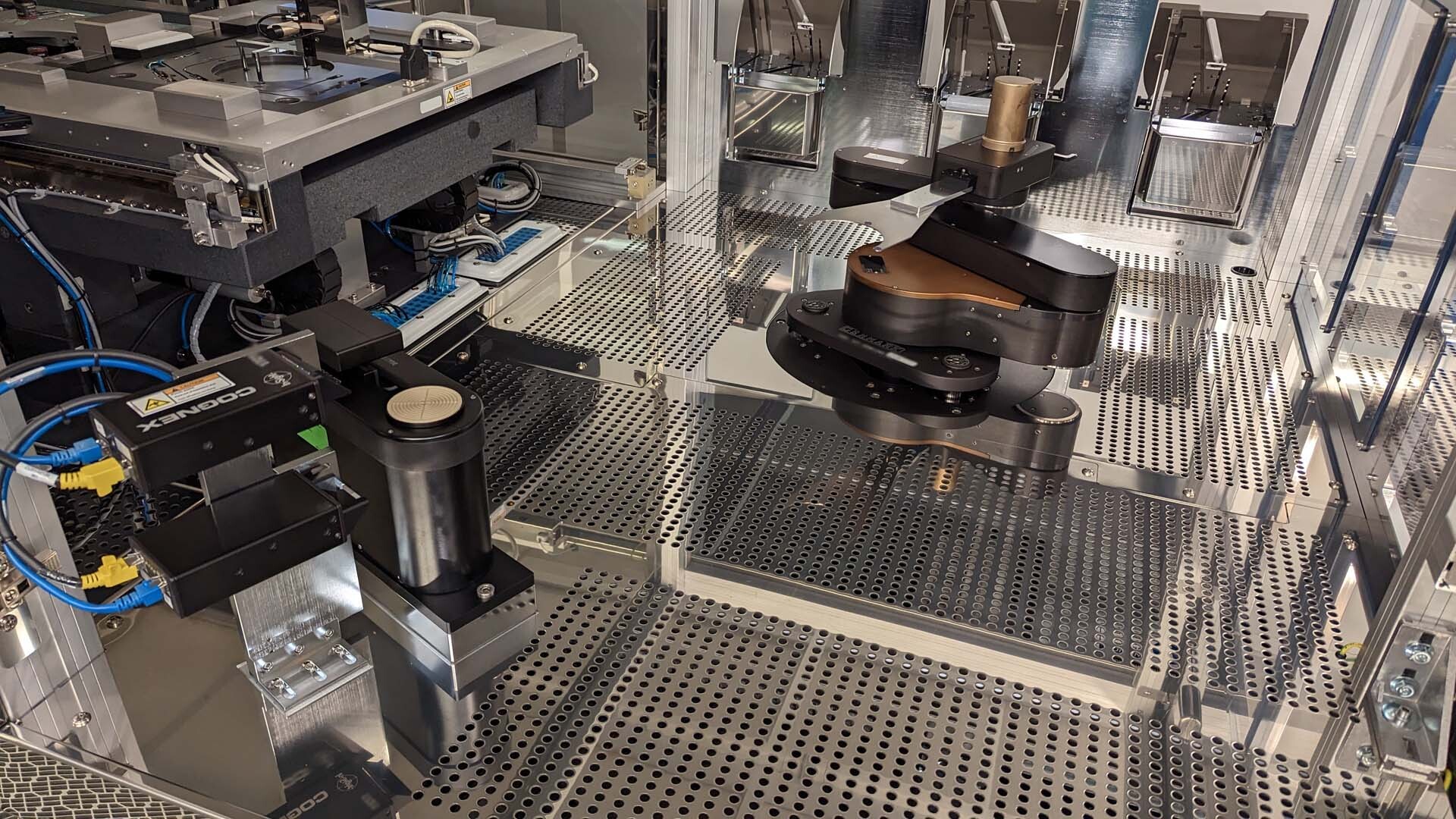

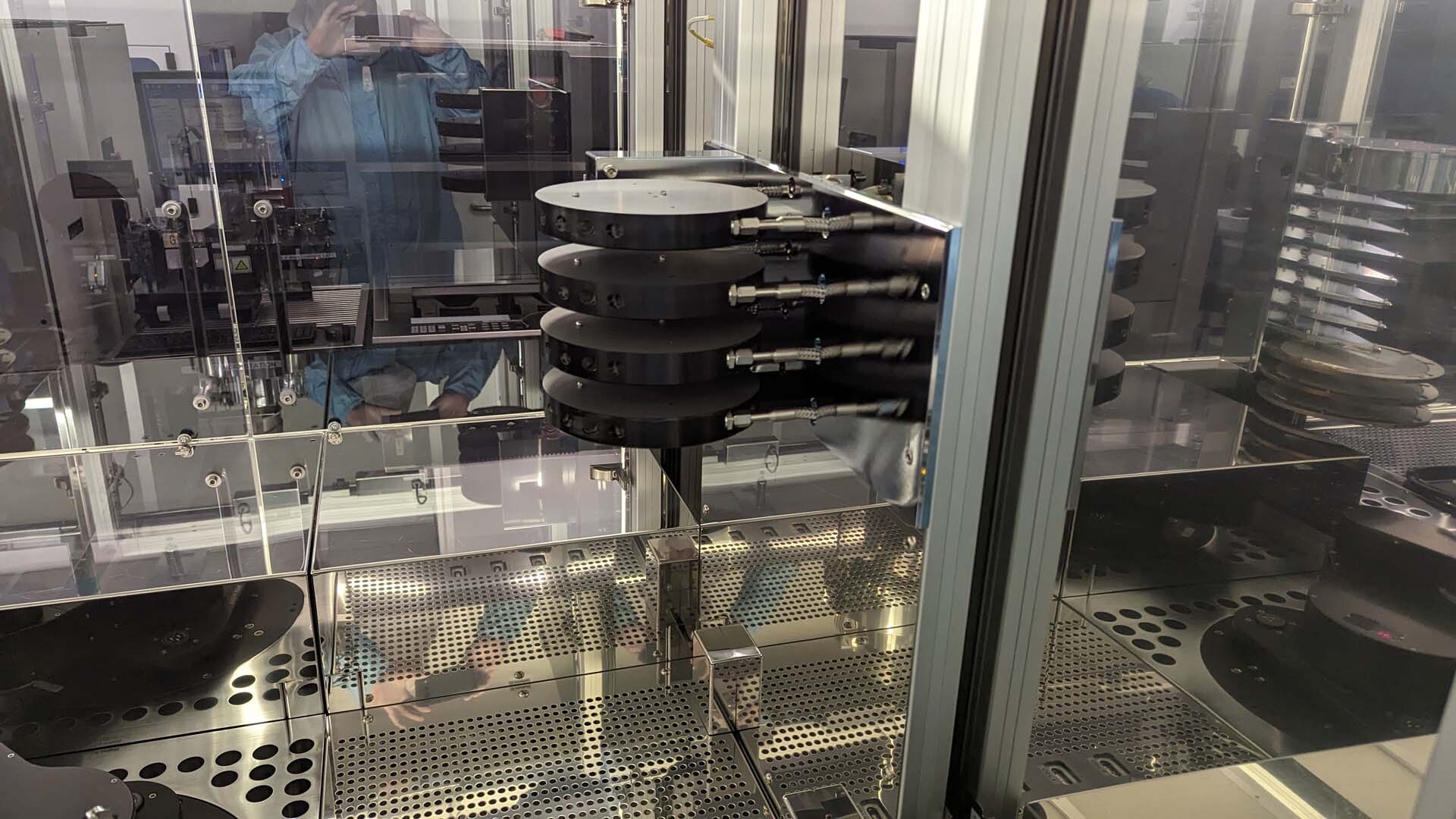

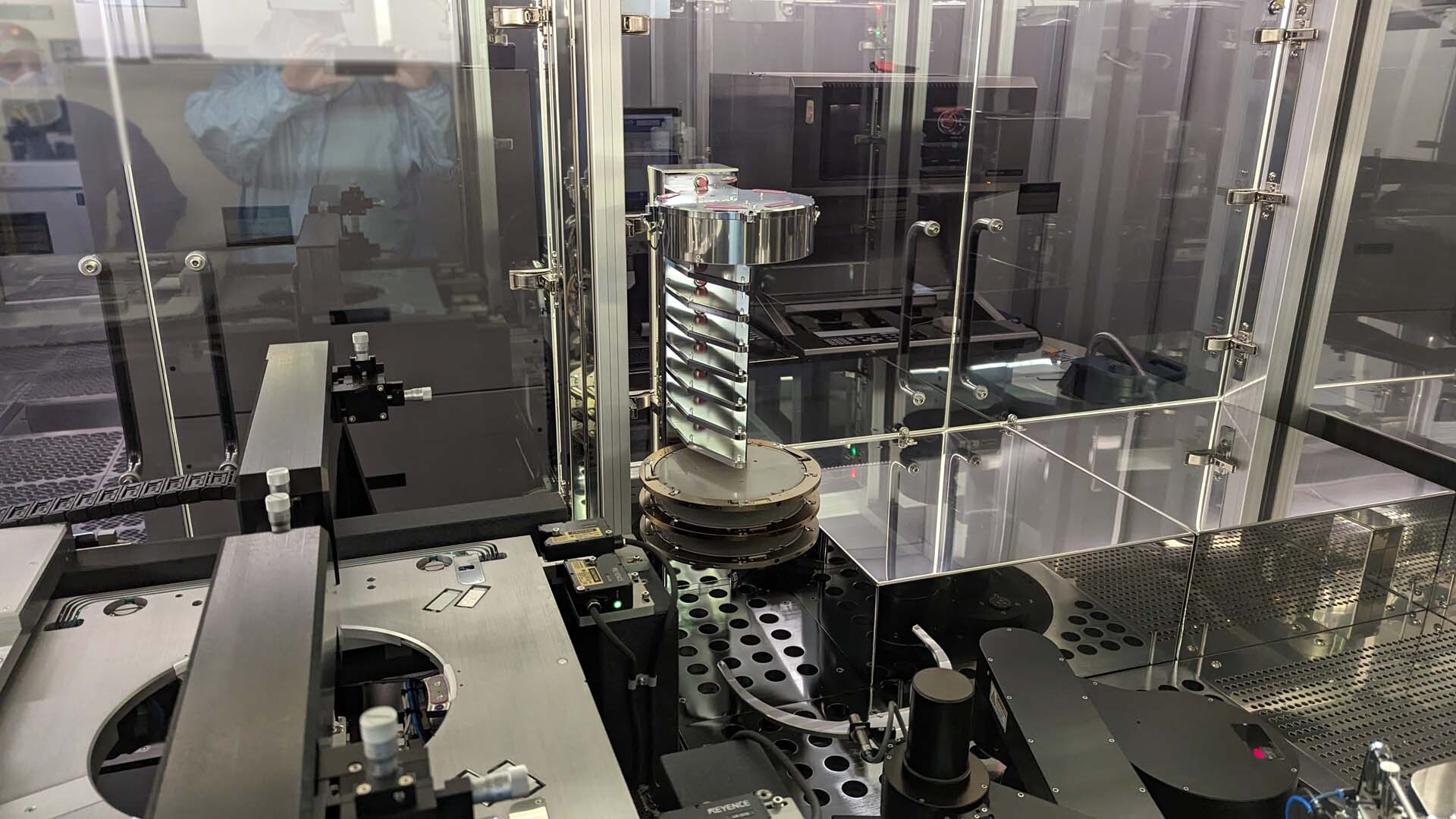

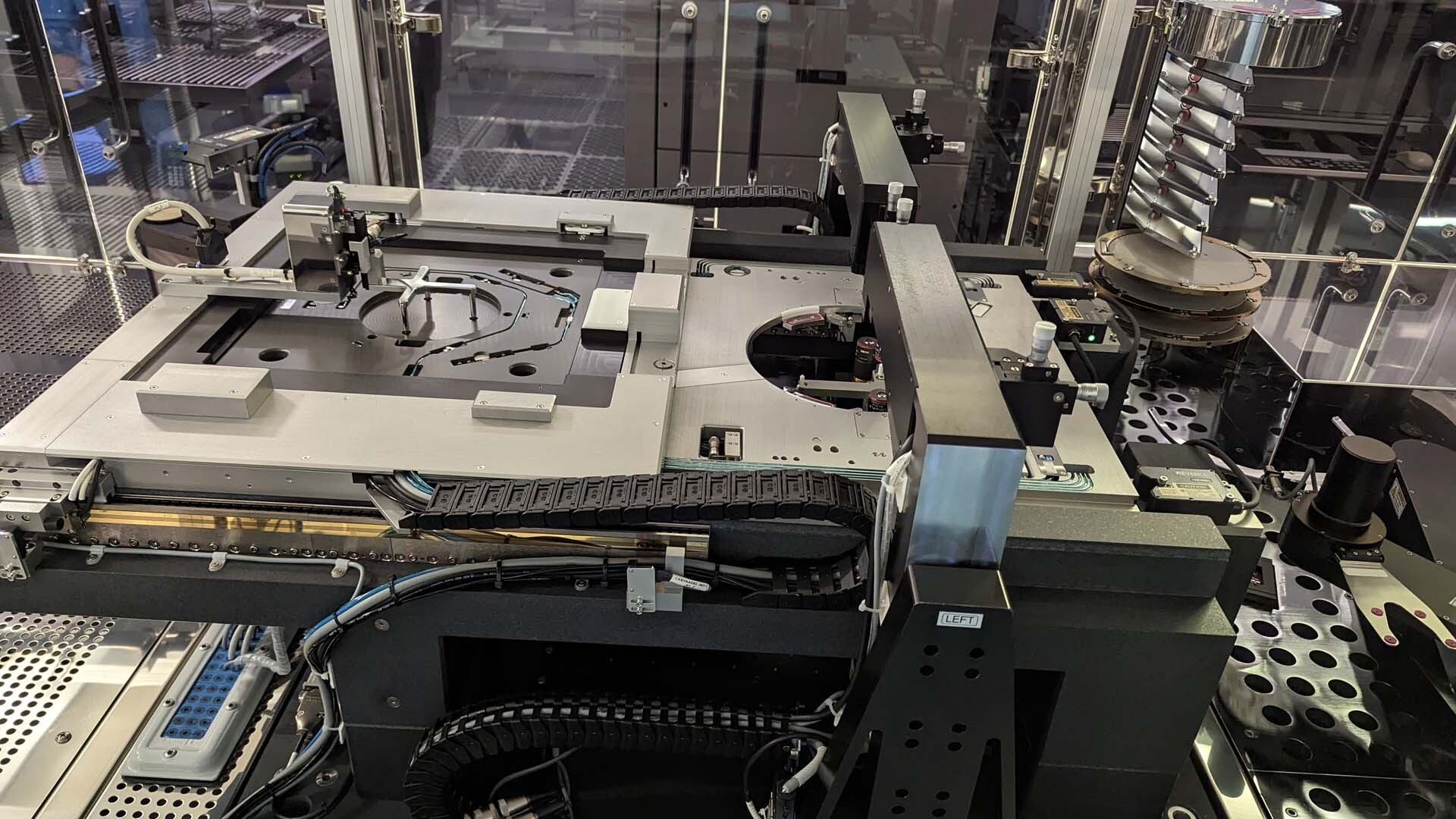

Ballroom substrate handling module

Bondchuck handling module

Linear transfer station

Ergo load cassette station

Scanning endeffektor for wafer handling robot unit

Bond chuck ID Tracking

Offline recorder

Operating system: Windows.

EVG / EV GROUP Gemini is a state-of-the-art precision bonding equipment designed for back-end and front-end applications in advanced packaging processes. EVG Gemini uses a high-speed wafer-handling robot and a rapid-turnaround gas delivery system to enable the rapid and efficient bonding of multiple die per waffle-pack. It is engineered for the semiconductor industry with particular attention to process repeatability, contamination control and low overall costs. The primary design feature of EV GROUP Gemini is its dual-column, monochromatic quartz optics. This setup provides extremely sharp film of light with a 10:1 depth-of-field ratio over a large working field. The light intensity is controlled by a combination of both UV and visible module shutters. The quartz optics also rapidly and accurately focus on both the top and bottom of the wafer or die, enabling full coverage and accurate alignment of the die or wafer. Gemini also includes a unique alignment unit with a unique, automated sensor mounted on a moving platform. This machine requires the user to input the desired alignment pattern for each die or wafer and the tool will automatically adjust the sensor to achieve the optimal alignment. This eliminates the need for manually adjusting the position of the die, leading to significant time and cost savings. The process head of EVG / EV GROUP Gemini also features a gas delivery asset that provides precise control of gas flow and pressure, as well as an optic head that is capable of rapidly exchanging optics on-the-fly, allowing the user to rapidly switch between different bonding and/or debonding processes. EVG Gemini is particularly well-suited for advanced packaging processes as it includes a pressure-controlled bonding chamber to eliminate air flow and potential contamination. The pressure control model also reduces process time, leading to faster throughput and improved yields. Overall, EV GROUP Gemini was designed for rapid testing, efficient process control and low cost of operation. It is the perfect choice for companies looking to improve their bonding processes and quickly reduce production costs.

There are no reviews yet